Life Science Optics

Microscope objectives are the heart of an imaging system. Objectives not only dictate image formation, but their design is critical for optimizing illumination uniformity and camera selection to maximize resolution and system throughput. Objectives maximize fluorescence signal collection from the sample and minimize wavefront distortions through the optical path, thereby enabling accurate image representation of the samples while maximizing sensitivity and accuracy. However, most off-the-shelf objectives available and in use today limit imaging throughput. This is because objectives are generally optimized for illumination and imaging performance near the center of the field of view (FOV), and color correction may be limited for specific applications.

Another limitation is the difficulty to precisely quantify or model the actual performance of available off-the-shelf objectives that are designed to work with specific tube lenses. Optical modeling of the objective and tube lens combination is needed to achieve optimal optical system design for throughput and cost. Overall, commercial objectives generally exhibit high performance variability and thermal sensitivity, failing to meet today’s demanding instrument repeatability requirements for quantitative imaging applications.

By specifically addressing your requirements, our custom optical designs reduce your overall system complexity and minimize cost while significantly improving performance compared to off-the-shelf objective solutions.

We combine advanced optical design and manufacturing technology with decades of experience in critical applications, and our global manufacturing and engineering support are ready to take you from first designs to ongoing marketplace success.

Optical Assemblies

Multi-element objective and tube lens assemblies, custom-designed, precision-crafted, and tested to meet your exact performance requirements.

Illumination Solutions

Fully integrated illumination engines with custom-engineered beam-shaping and calibrated to deliver the light precisely where and how you need it.

Optomechanical Assemblies

Fully assembled optical units, mounted and calibrated to perform in your product.

Complete Optical Systems

Complete photonic solutions, from the light source to the detector, ready to plug into your instrument.

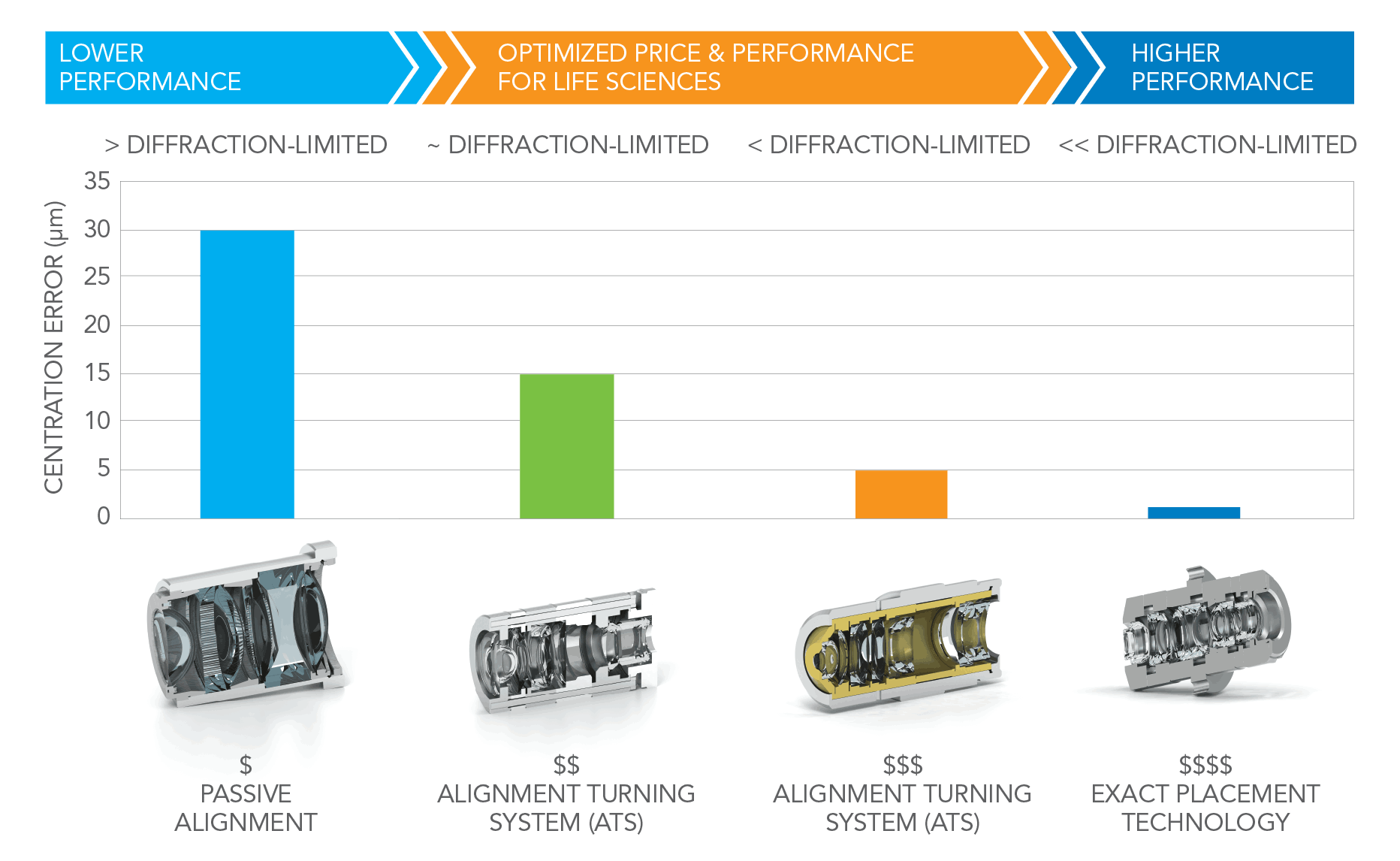

At IDEX Health & Science we recognize our customer’s unique needs of each optical system, and we develop custom design and manufacturing solutions that optimize price and performance.

We use state-of-the-art manufacturing techniques and processes, along with the most advanced measuring metrology tools and vertically integrated production capabilities. The result is a robust and reliable product, with superior and consistent system-level performance from prototypes to high volume production.

By working closely with our customers, we have routinely completed challenging projects successfully, meeting aggressive timelines and cost constraints, and delivered optimal solutions for the most demanding applications for high-throughput and high-resolution subcellular imaging in life science and medical instrumentation.

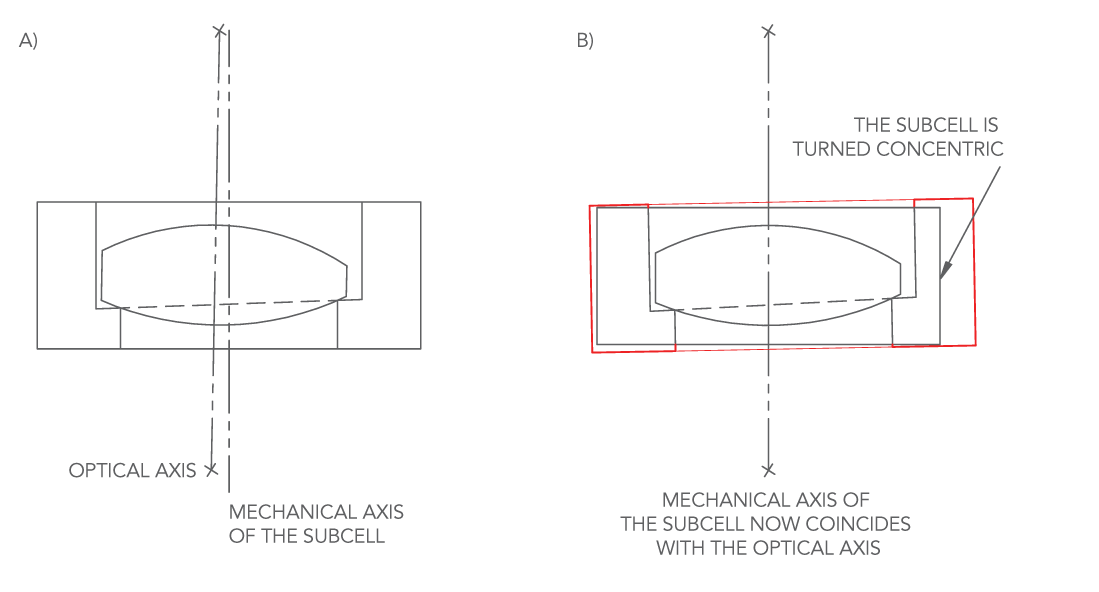

A) The optical axis of the mounted lens is determined,

B) The subcell is trimmed to final size with its outer diameter aligned parallel to the optical axis.