Fluidics

Reduce air bubble and dissolved gas interference in your fluidic system and improve the analysis result quality with IDEX Health & Science degassers.

Dissolved gases in reagent lines can lead to bubble formation, disrupting analysis results and causing errors in fluidic systems. IDEX Health & Science inline degassing modules efficiently remove dissolved gases from a variety of fluids, ensuring optimal fluidic performance for your instrument. The fully swept flow design of our degassers ensures minimal hydrodynamic impact; dissolved gas level can be conveniently controlled through our adjustable vacuum pumps / vacuum degasser systems.

Improve analysis result quality

Inert materials offer chemical compatibility across a broad range of buffers and reagents

Simple integration

Get started on your degasser project and access degasser resources.

*Required field

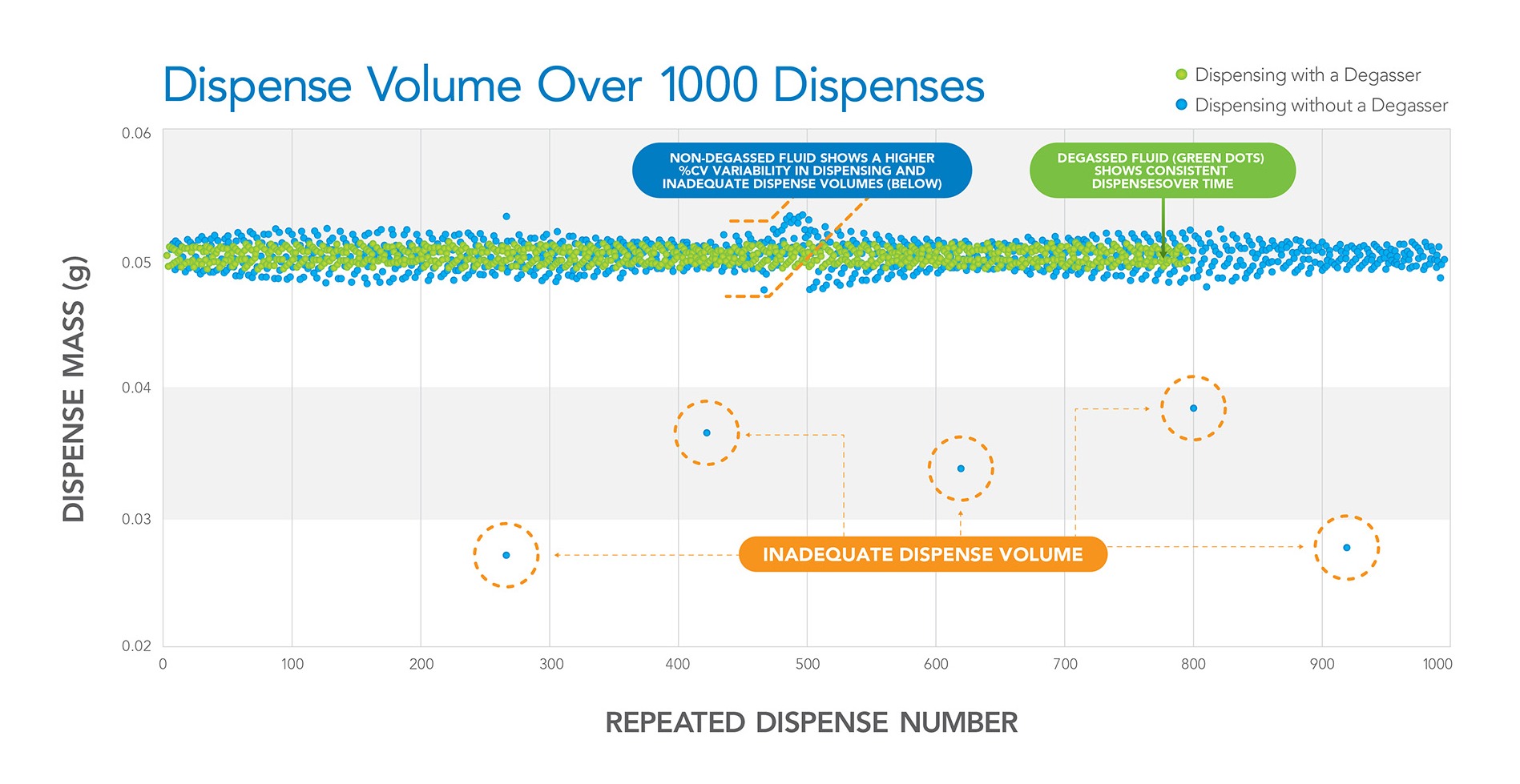

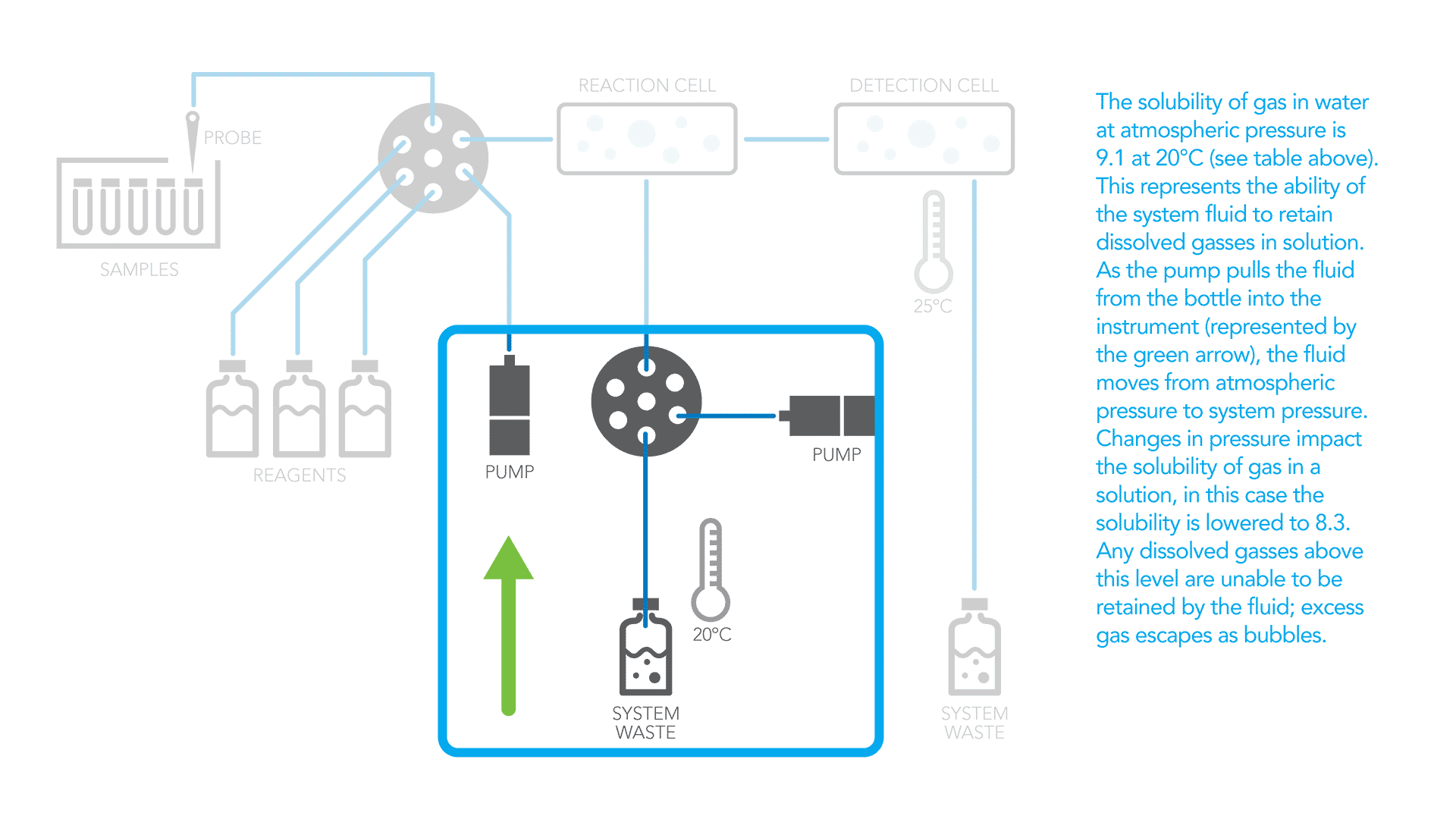

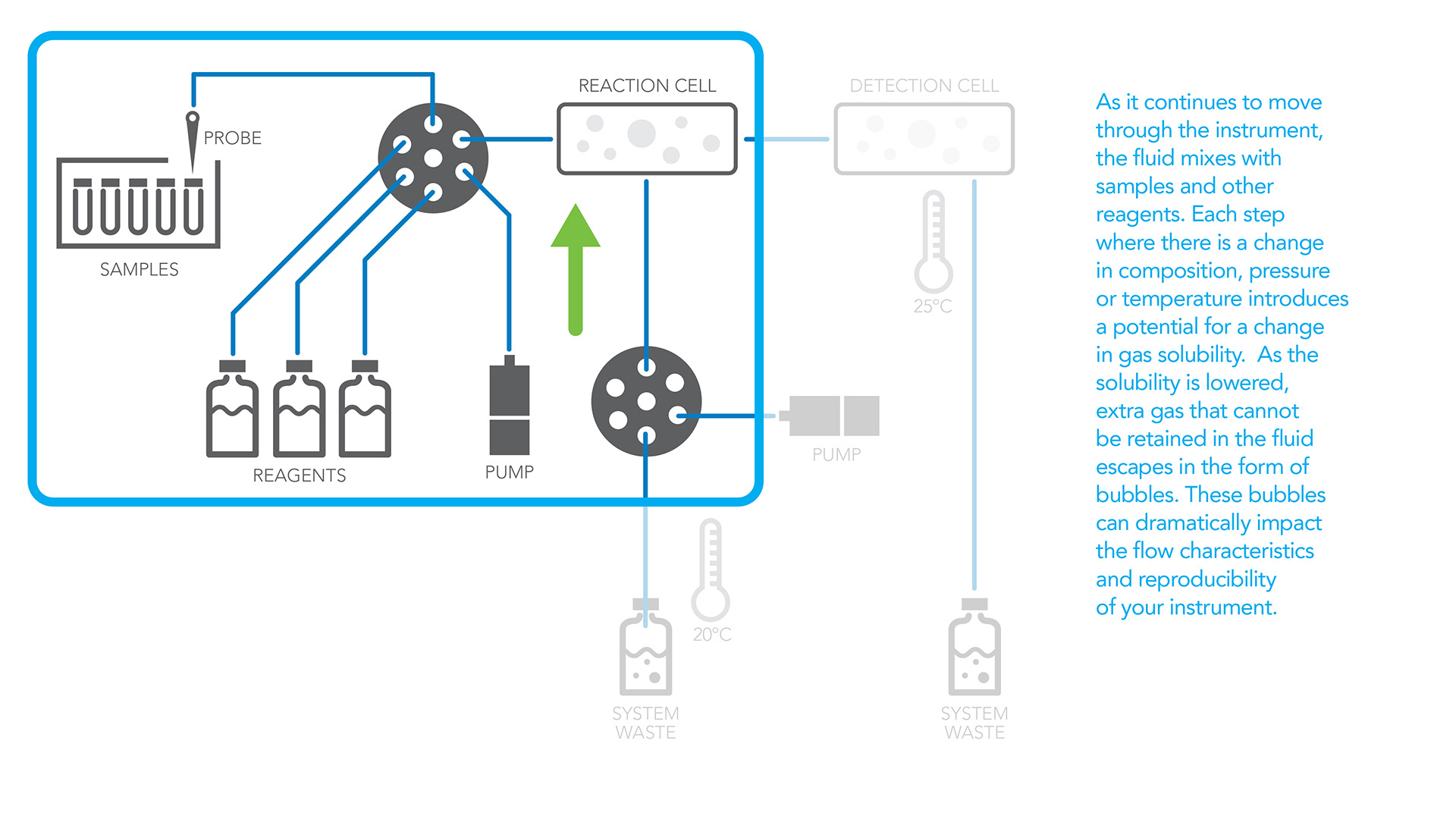

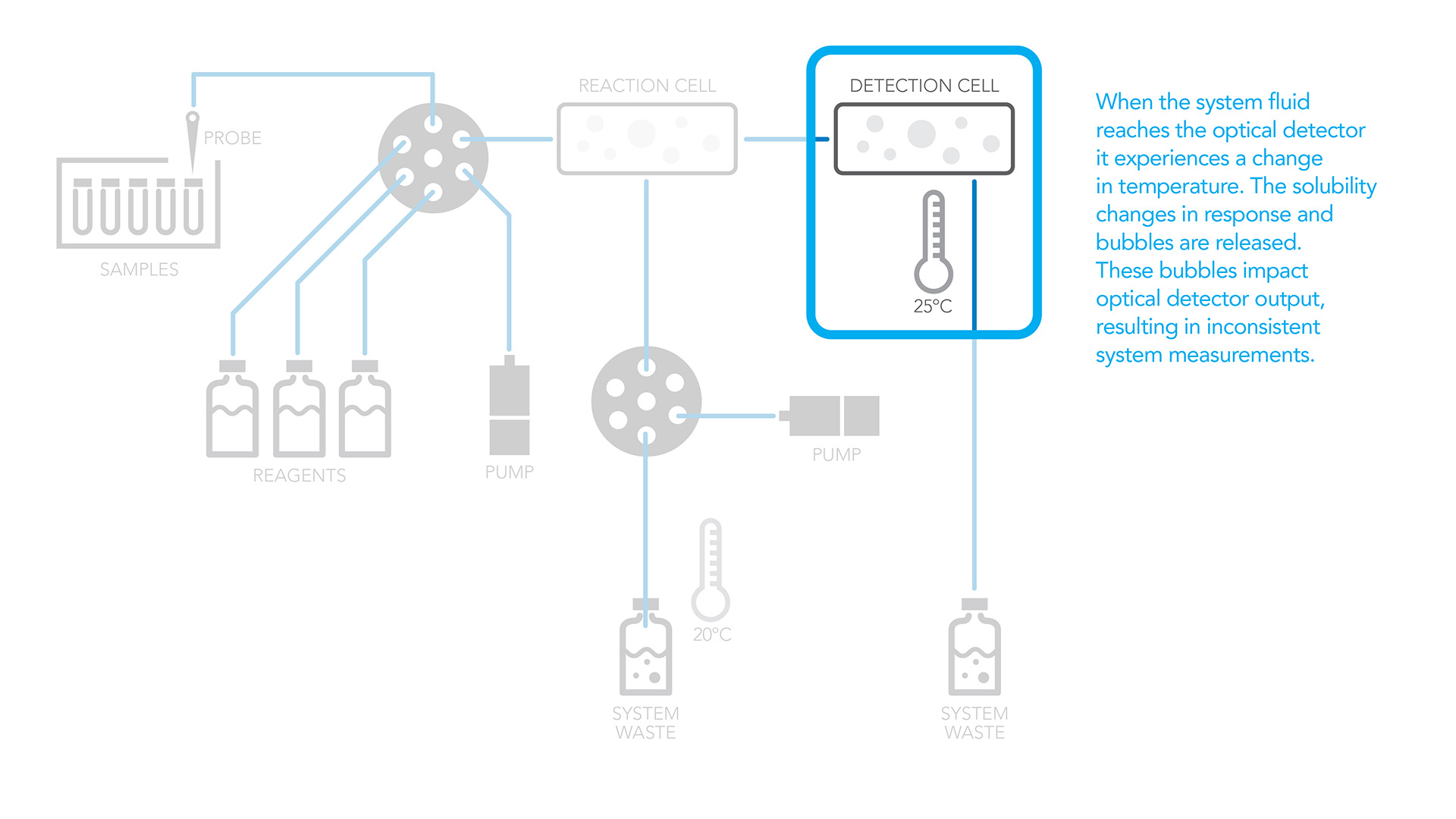

Dissolved gasses can cause issues with your instrument precision. Changes in the temperature, pressure, or reagent mixing can cause the gas solubility of your system fluid to change. When this happens, your pumping precision can be dramatically impacted.

This experiment shows repeated dispenses of 50µL with and without an in-line degasser inline. In this experiment, we changed the temperature of the water from 4°C to 20°C. Without a degasser in-line, the dispense accuracy of the pump is varied, showing a higher %CV of reproducibility and a few dispenses that are far below their expected value. This is due to dissolved gasses in the water outgassing with the temperature change. Bubble formation and aggregation can lead to dispensing anomalies in your instrument design. With the test repeated and an in-line degasser added, the reproducibility of the system dispense is greatly improved.

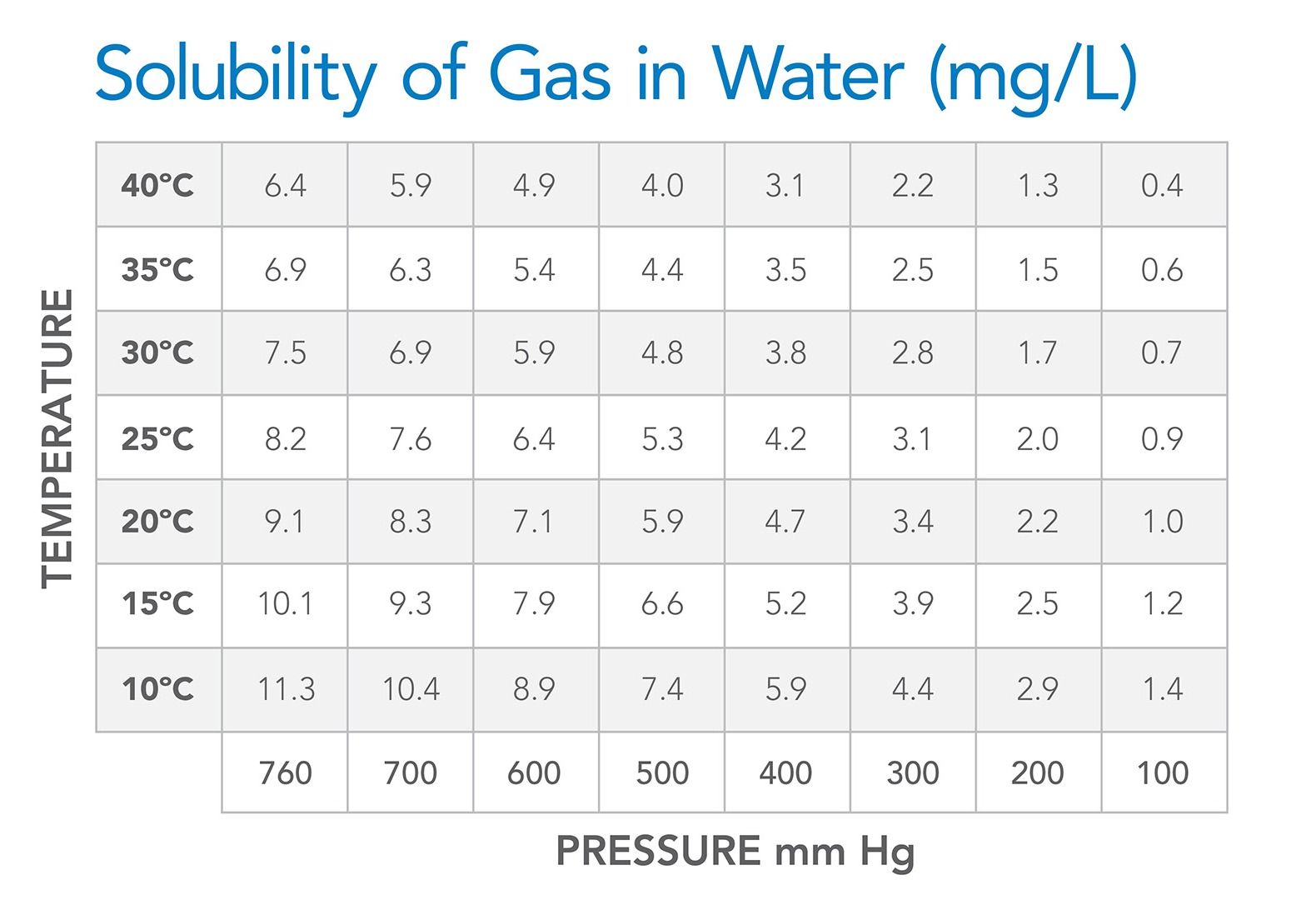

Henry’s Law establishes the relationship between gas solubility and temperature. A common example of Henry’s Law is demonstrated when a bottle of soda is opened, the carbon dioxide gas rapidly escapes because the decrease in pressure lowers its solubility in the liquid.

For most gases, increasing temperature leads to a decreased solubility in solution. How this impacts instrument design can be demonstrated in the below images:

We specialize in designing and manufacturing custom degassers tailored to meet the unique requirements of your application. With over 50 years of experience, our team of experts combines cutting-edge technology with unparalleled craftsmanship to deliver solutions that enhance efficiency, reliability, and performance. Our solutions can work with your on-board vacuum pump, or with our proven vacuum solutions.

Improve data quality and reliability in your system with degassing chambers from IDEX Health & Science. Find the best degassing chamber for your application by reviewing the data sheets below.

Degassers are used in High-Performance Liquid Chromatography (HPLC) separations to reduce dissolved air during mobile phase degassing. The mobile phase state will aid in the proper identification of compounds separated by the HPLC system, along with the stability of the system flow rate. For this reason, nearly all HPLC systems include some form of degassing of the mobile phase and, in some cases, a separate degasser channel is used to improve the accuracy of the autosampler.

Learn more about HPLC degassers and their critical functions in HPLC degassing.