The Function of a Degasser in HPLC

What is the Function of a Degasser in HPLC

Degassers are used in High-Performance Liquid Chromatography (HPLC) separations to reduce dissolved air from the mobile phase solvent. The mobile phase state will aid in the proper identification of compounds separated by the HPLC system, along with the stability of the system flow rate. For this reason, nearly all HPLC systems include some form of degassing of the mobile phase and, in some cases, a separate degasser channel is used to improve the accuracy of the autosampler.

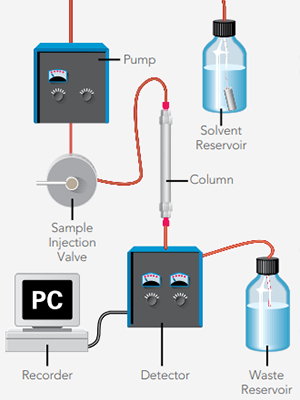

Caption: An example HPLC flow path depicting a complete Degassing system.

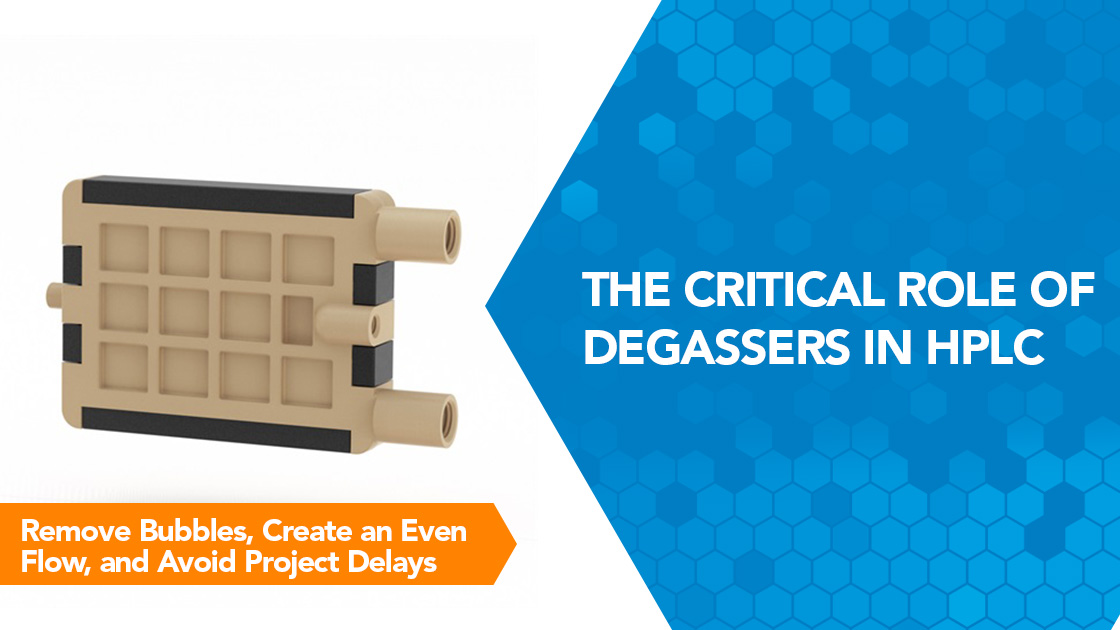

The Critical Functions of Degassers in HPLC Applications

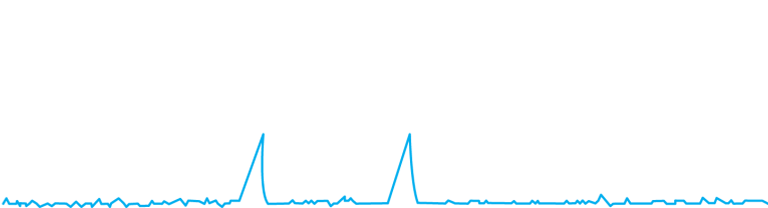

Degassers Remove Bubbles Created During Mobile Phase Degassing: Degassers are necessary for HPLC (High Performance Liquid Chromatography) applications to ensure the mobile phase is free of dissolved gases. Dissolved gases during this process can lead to bubble formation and failures in the pump or check valve impacting the continuous flow and retention time in your fluidics instrument platform. The result is an uneven flow path and abnormal peaks, as depicted in the chromatograph below. Degassers greatly improve precision by degassing fluids far below the saturation point, so instrument operations remain bubble-free and have a smooth consistent flow.

Caption: A chromatograph showing peak failures and distortions in an HPLC system.

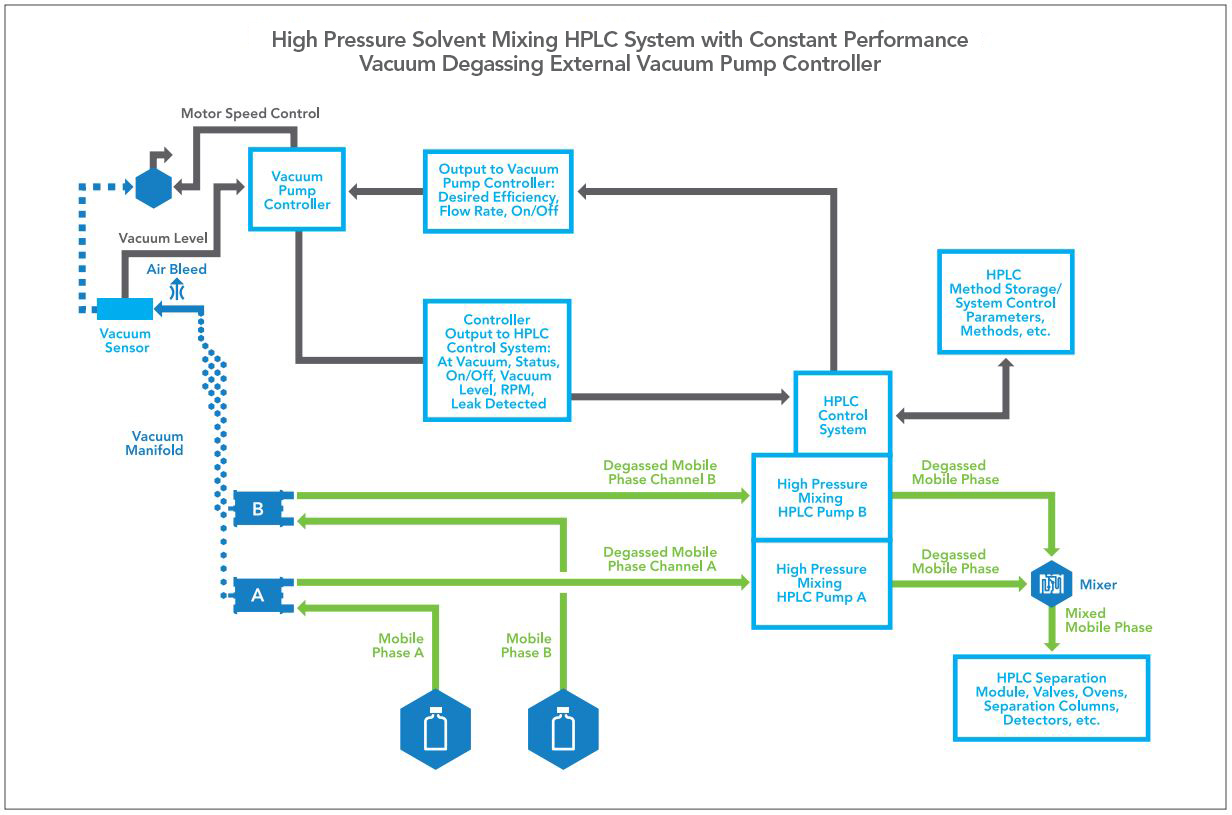

Degassers Create an Even and Constant Flow in Your HPLC System: Degassers minimize the movement of solvent vapors across the membrane – a process known as pervaporation – to reduce concentration changes in mixed mobile phase degassing and, at the same time, minimize the amount of solvent vapor discharged into the laboratory. This enables consistent, even flow operation that reduces pervaporation. It also provides the ability to integrate the degasser into the separation method control protocol and select a given efficiency for an HPLC system—you can dial up or down to get the exact specifications you need regardless of the applied vacuum. Reduction of pervaporation from pre-mixed mobile phases leads to more consistent chromatography results.

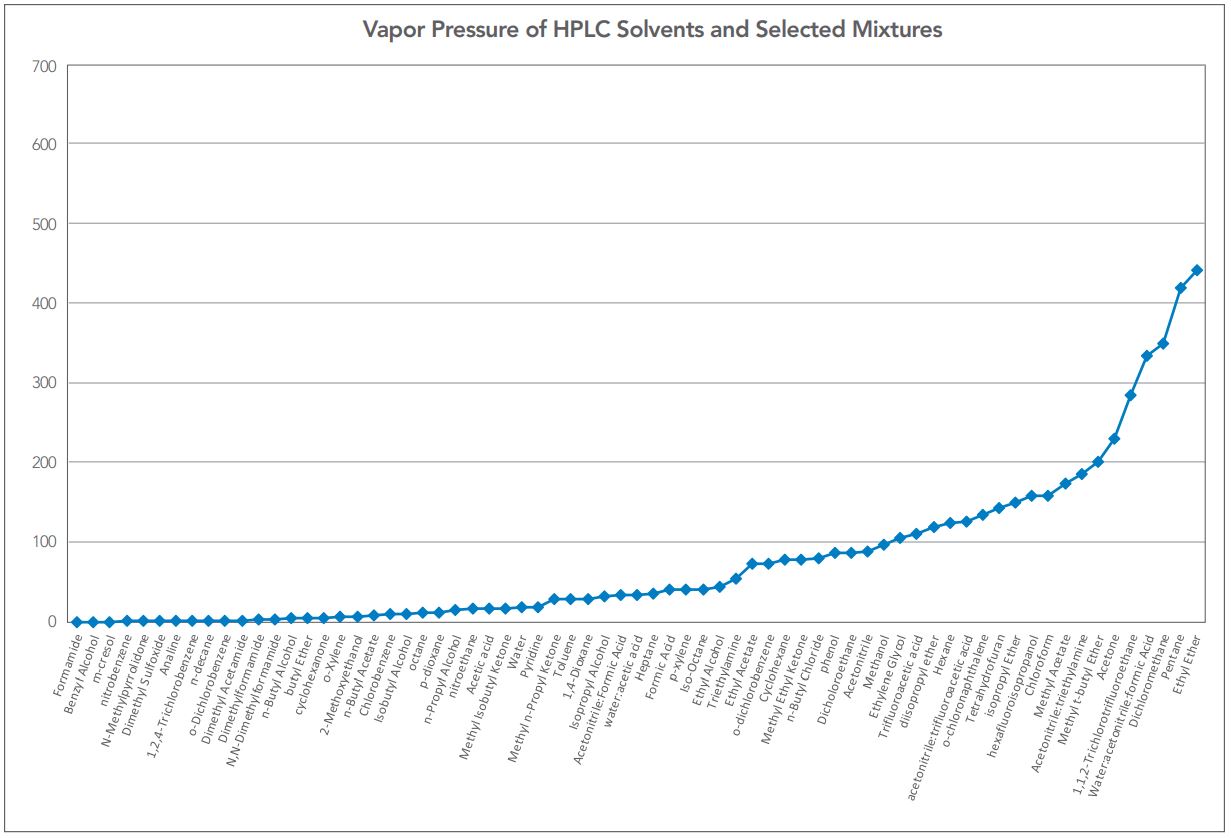

Caption: Vapor pressures of most HPLC solvents.

Degassers Help Avoid Disruptions and Delays in the Development Process: Implementing a Degasser in your HPLC system can speed up your development and discovery timeframe. With fewer dissolved gases, you will have fewer bubbles and ultimately fewer failures. You will get more consistent data to help you move quickly from testing to results—speeding up your time to market.

Why Trust IDEX Health & Science Your HPLC Degassing?

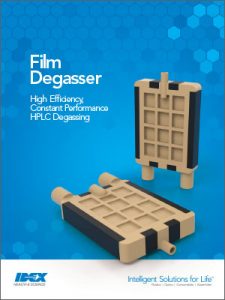

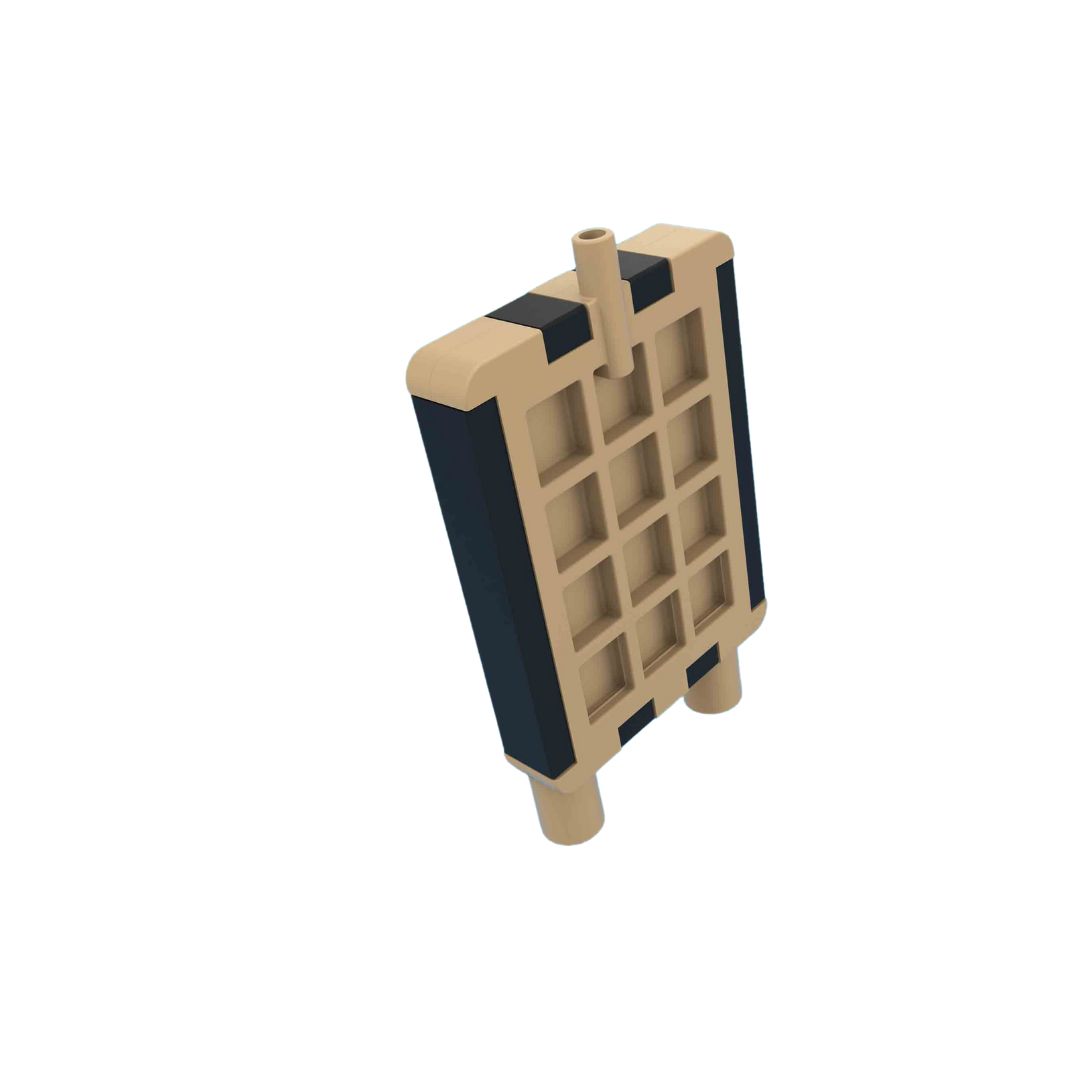

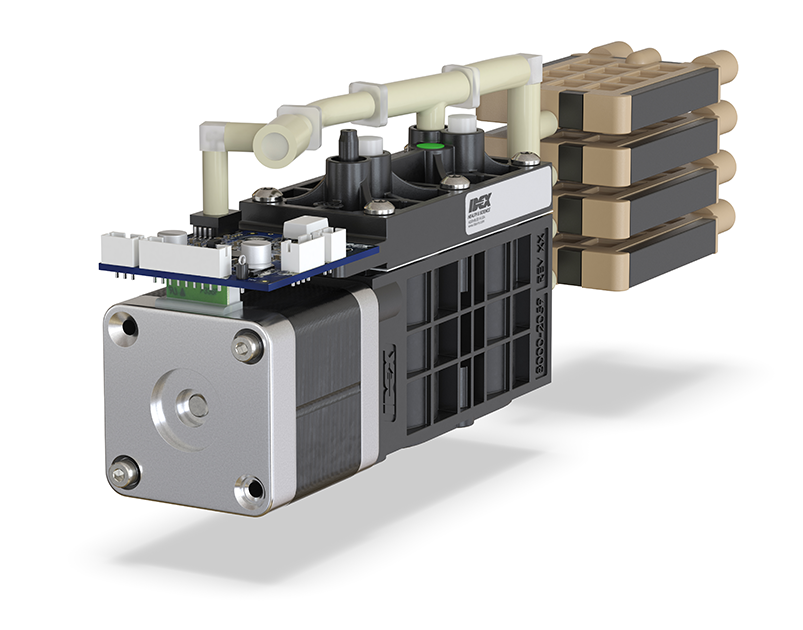

We have developed a cutting-edge technology that when paired with our film degasser chamber enables you to select a fixed degassing efficiency irrespective of flow rate ideal for mixed mobile phase degassing. Reduce air bubble and dissolved gas interference in your fluidic system and improve the analysis result quality with IDEX Health & Science degassers:

- Improves analysis result quality

- Inert materials offer chemical compatibility across a broad range of buffers and reagents

- Simple Integration

- An exceptionally high-performance degassing chamber

- A controllable vacuum pumping system

- Bioinert for biopharma/LC applications

Enhance Stability in Your Fluidics with our Next Generation Degassing Vacuum Control System

This degassing vacuum control system, when integrated with the IDEX Health & Science Film Degasser, provides powerful performance control with increased solvent compatibility. A degassing system with the film chamber and vacuum pump enhances performance and efficiency.

Degassers are Ideal for Life Science Applications Including:

Our degassing capabilities support powerful performance control with increased solvent compatibility to meet your analytical workflow needs.

Learn About Our Degassing Capabilities

Fill out the form to get started on your degasser project

*Required field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

Related Resources