HPLC Help Center

High Performance Liquid Chromatography (HPLC) is an analytical process designed to separate, quantify and analyze components of a chemical mixture. Ultra-High Performance Liquid Chromatography (UHPLC) is HPLC operated at extremely high pressure (>12,000 psi / 800 bar).

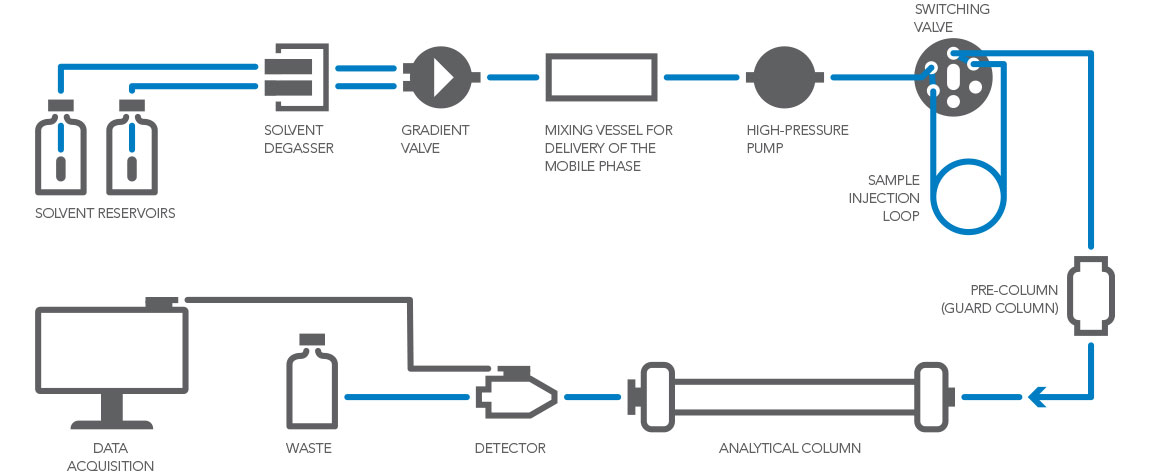

Samples of interest are introduced to a solvent flow path, and then carried through a column packed with specialized materials for component separation. Component analysis is obtained using a detector coupled to a data acquisition system. All this occurs under pressures which, on modern systems, may reach or exceed 20,000 psi (1400 bar)!

The basic components of an HPLC system include solvent reservoirs, solvent degassers, mobile phase high-pressure pumps, solvent mixer, sample injector (switching) valve, analytical column, detector, data acquisition system, and waste reservoir. Other important elements often included are an inlet solvent filter, post-pump inline filter, sample filter, precolumn filter, and back-pressure regulator. The function of each of these components is briefly described below.

Solvent flow through an HPLC system begins in the solvent reservoirs, which contain the solvents used to carry the sample through the system. The solvents should be filtered through an inlet solvent filter to remove any particles that could potentially damage the system’s sensitive components.

The pumps propel the solvent through the system after they are degassed. Mechanical action within the pump can create some particulate material in the fluid stream, so an inline solvent filter is useful in preventing any post-pump component plugging or damage.

The next component in the system is the switching valve (or sample injector), also known as the injection valve. This valve, equipped with a sample loop of the appropriate size for the analysis being performed, reproducibly injects plugs of sample into the flow path. Because the sample often contains particulate matter, it is often important to utilize either a sample filter or a precolumn filter to prevent valve and column damage. Limitations on sample size can require very small sample filters.

Following the injection of sample, an analytical column separates the sample plug into its various components. This is based on the differential attraction of the sample components for the solvent and the packing material within the column. A sacrificial guard column is often included just prior to the analytical column to chemically remove components of the sample that could foul the separation column, hinder the separation, or interfere with other downstream processes.

Following the analytical column, the separated components pass through a detector before they pass into the waste reservoir. Common detector types include optical absorbance, fluorescence, or Mass Spectrometric. Sometimes a combination of different detector types is used. Sophisticated data acquisition and analysis systems are available for all detector types, and these systems offer significant analytical and report generation capabilities.

Solvent degassers and back pressure regulators are often installed into the system. Solvent degassing prevents the formation of bubbles when mobile phase components are mixed in the system and backpressure regulators limit pressure drops along the flow path that might encourage further bubble formation. Backpressure regulators are placed downstream of detector cells so they don’t create sample band broadening ahead of detection. Bubble prevention is important because bubbles in a flow cell or mass spectrometer source can interfere with the detection of sample components. Alternatively, an inert gas sparging system is sometimes installed to force dissolved gasses out of the solvents being stored in the solvent reservoirs.

Each of the components described above requires fittings to couple it into a system.

It is important to note that improper selection or installation of these fittings can lead to leaks or the formation of dead volume, both of which can result in poor HPLC performance.

Please contact one of our distributors or IDEX Health & Science directly if you have any questions regarding fittings or the various components that make up an HPLC system.