Fluidics

Move fluids precisely in your fluidic system while reducing downtime with pumps from IDEX Health & Science.

Modern applications with demanding chemistry require a high-performance fluid actuator. Our durable motorized pistons enable you to precisely control fluid motion in your instrument. Long lifetime is delivered through a highly engineered, static sealing solution versus a limited lifetime, dynamic sealing mechanism accompanying a syringe pump. With wide chemical compatibility, IDEX Health & Science pumps provide you confidence for your complex fluidic application needs.

Handle demanding salt and detergent solutions reliably without extra complexity

Easily integrate a high-precision pump in your system

Enhance your design through customization

IDEX Health & Science manufactures several families of positive displacement piston pumps, for you to have a choice when designing your automated analysis instrument. These pumps can be off-the-shelf or customized to provide you with the desired level of performance needed for your fluidic distribution system. View our Pump Selection Guide.

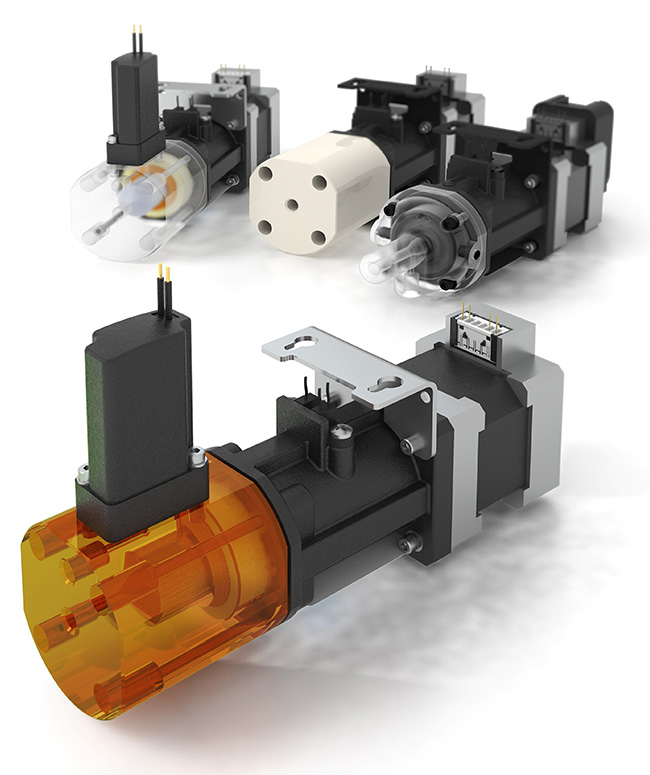

V-Series: Offer flexibility and maintenance-free performance to tackle tomorrow’s fluidic challenges, this line of pumps is designed for lower-pressure applications, < 1,000 psi / < 70 bar. The V-series positive displacement pumps provide precise fluid dispensing for a variety of clinical and laboratory instruments. With an anticipated life of 2 million cycles and a molded acrylic (PMMA) pump head, this pump provides an economical balance of precision for applications requiring a lower number of pump cycles.

VP17 Series: Providing precise dispensing and life-of-instrument reliability. The VP17 utilizes molded acrylic fluid chambers combined with a drivetrain that is designed to last 5 million cycles. The VP17 offers exceptional value and industry-leading performance, with the ability to adapt to your system by customizing sensor feedback, electrical connections, and mounting options.

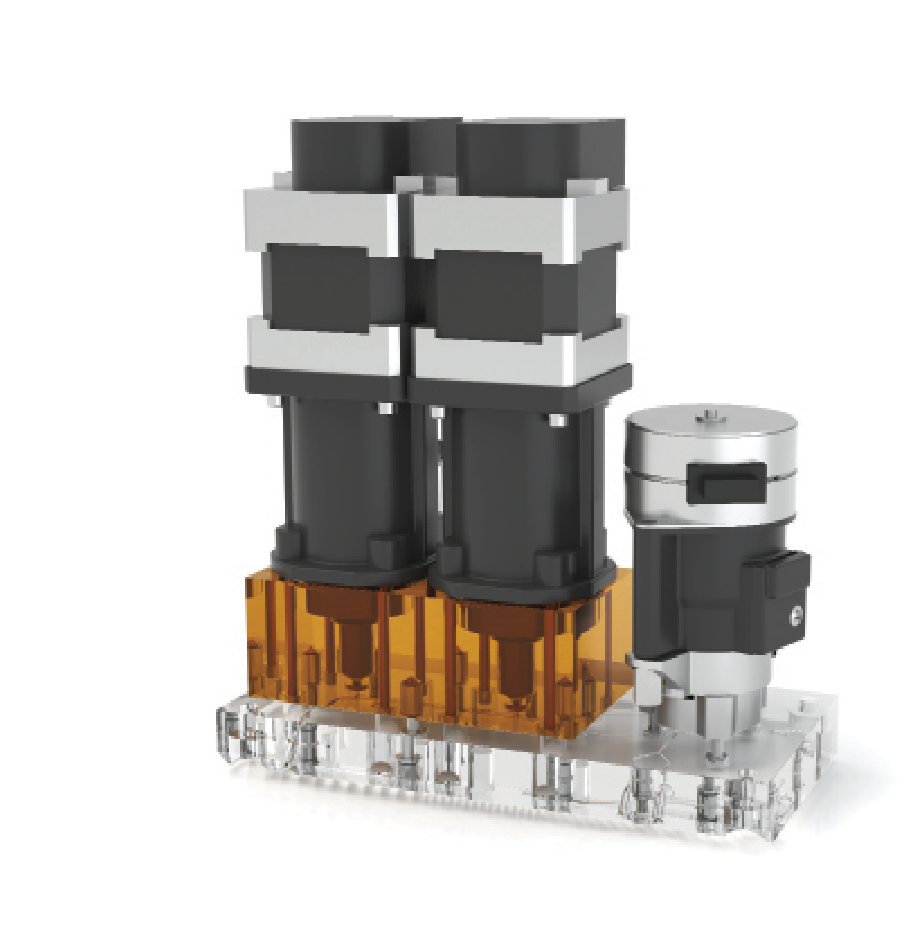

VFP-17 Series: Allowing for custom mounted valving, each VFP17 pump is machined to incorporate a fluidic path that minimizes unswept volume. Assembled with a drivetrain that is designed to last 5 million cycles and the ability to combine with a head machined from a variety of materials to ensure chemical compatibility with your instrument. Whether used as a single pump, or combined with multiple units in a fluidic manifold, the VFP17 has proven to be a flexible and maintenance-free solution for OEM instrument designers.

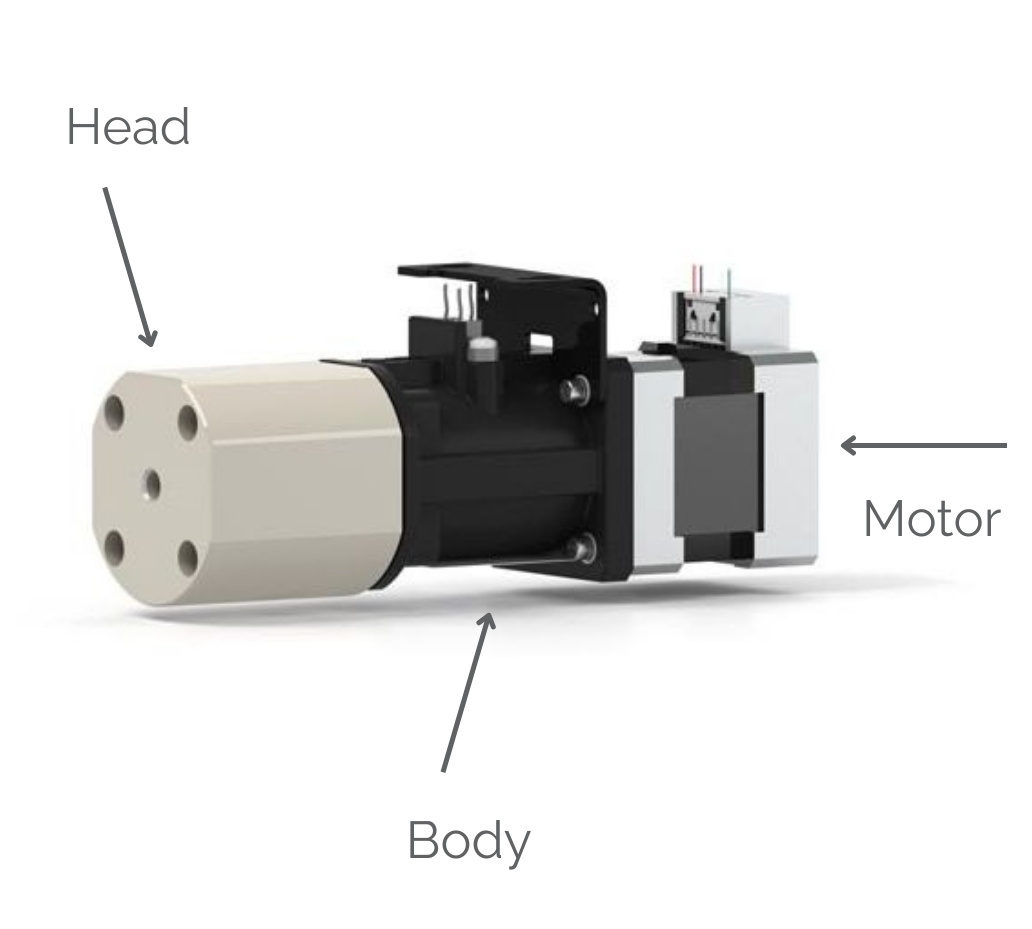

Our motorized piston pump consists of three primary sections: the head, the body, and the motor.

The head is the fluidic interface of the piston. Here the piston comes in contact with fluids and displaces them; high-performance seals in the pump head prevent fluids from entering the body. The body houses a precision drive train that converts the rotary motion of the motor into a linear displacement of fluids.

Position and optional motion feedback enable you to achieve a higher level of fluid actuation control by allowing you to account for load-related offsets. Electrical interfaces and mounting are located 180° from the fluidic ports, to avoid spill-over when handling the product.

The IDEX Health & Science pumps differ from regular syringe pumps in several ways:

A pump’s chemical resistance is achieved through multiple pump head and piston seal options. IDEX Health & Science can provide pump ports in several different thread patterns and geometries, depending on how the plumbing needs to interact with the rest of the system. VFP pumps are offered in a variety of different pump head materials (Acrylic, PEEK, Ultem, etc) to suit the demands of your application. Electrical connections, sensor output, mounting, and fluid port locations can be adjusted to your needs simplifying your integration design.

Pumps have three common port orientation options

Dynamics optimization can be achieved by various motor wiring configurations and drive train options. Precision and speed trade-offs can be made by customizing the lead screw pitch (20- or 40-pitch). Higher pitch screws create better step precision, but take more overall motor steps to achieve a given dispense volume. Piston driving forces can also be higher with higher-pitched screws, so the pressure rating can also increase.

Dispense applications can be challenging for systems pumping surfactants and salts. IDEX Health & Science has developed a piston pump to reliably withstand high concentrations of detergents and salt.

The IDEX Durable Seal solves challenges in 3 critical areas to deliver robust pumping performance:

These innovations have enabled the IDEX Durable Seal Pumps to perform reliably delivering precision with detergents and salts over the life of an instrument.

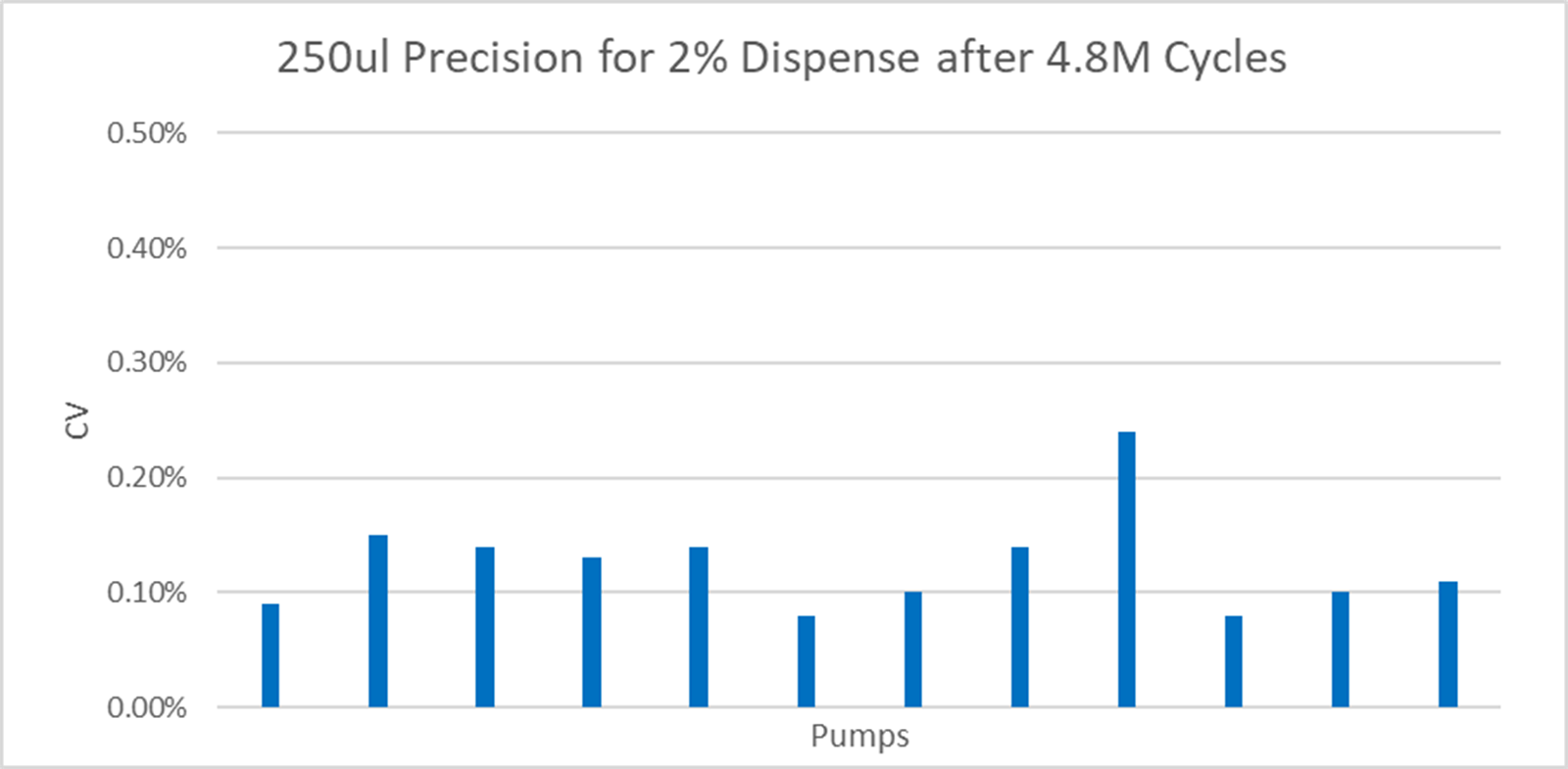

Precision and dispense after 12 pumps has cycled a salty, detergent containing buffer over 4.8M cycles.

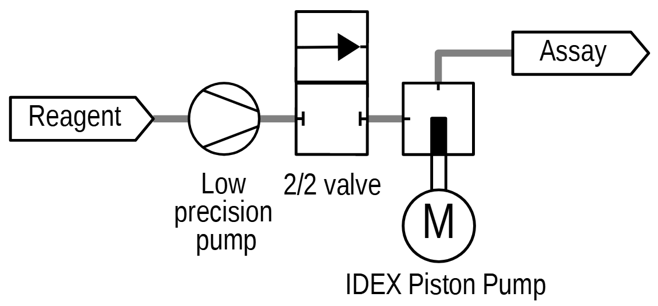

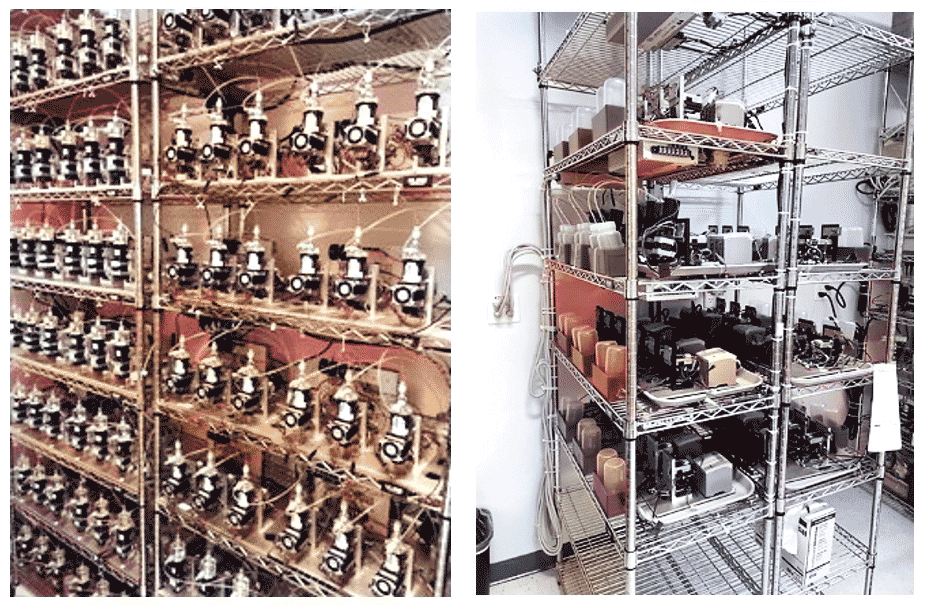

In many fluidic applications, pumps are used inline to facilitate priming and bubble clearance. For example, in a typical clinical laboratory instrument, our pumps work best when they manage the high precision side of fluid actuation while lower cost pumps are used for priming (shown to the left).

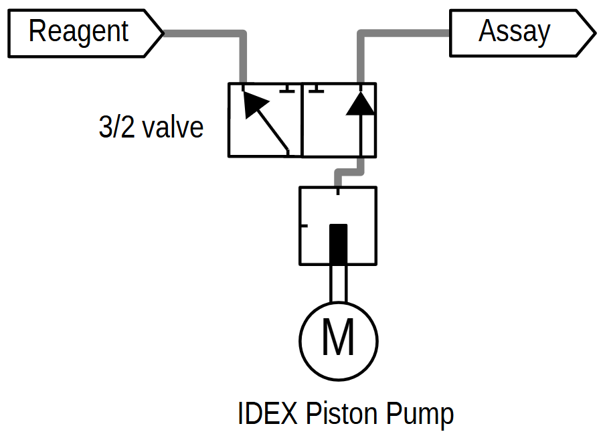

Self-priming can be achieved for instance by adding a 3/2 valve to the product yielding a configuration that provides one-directional. A convenient level of further integration can be achieved by adding either a single or multiple valves to the pump head.

For the implementation of complex fluidic networks and functionalities that improve your system throughput while reducing reagent consumption and carryover, IDEX Health & Science offers a higher-level integration when combining our piston pumps with our rotary shear valves, pressure sensors, and other components in multi-layer manifolds.

IDEX Health & Science’s line of HPLC Pump Components and subassemblies are designed for use in a wide range of liquid chromatography applications. Each component or subassembly is manufactured to the highest quality standards in our state-of-the-art manufacturing facility.

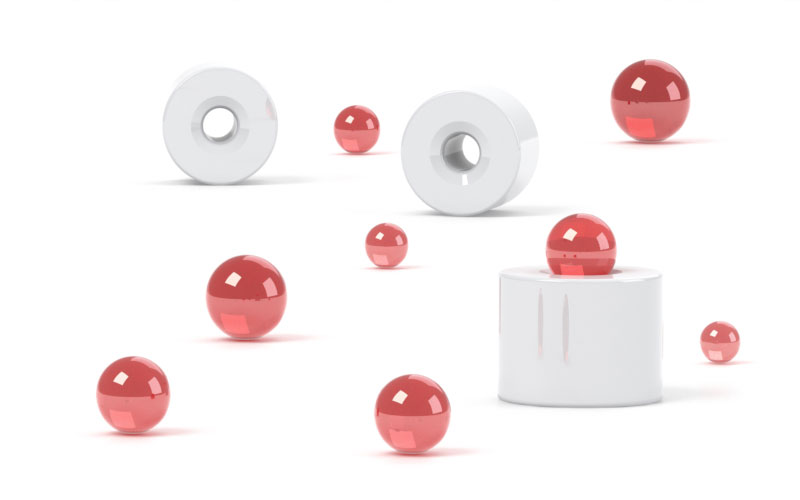

Precision Balls and Seats for High Pressure Check Valves are used in liquid chromatography pumps. Each ball and seat is precisely manufactured and 100 % tested to guarantee proper sealing. All balls and seats are tested and packaged in our class 10,000 clean room.

Ultra-High Pressure Check Valve (UHPCV) Cartridges have a superior design which maximizes lifetime while minimizing check valve leakage/pressure drop. Available as complete assemblies these cartridges are manufactured with our proprietary stronger alloy, enhancing absorption of structural stress- extending the life of the check valve. Our check valves can operate to pressures up to 30,000 psi (2,068 bar). Each check valve is performance checked prior to shipment.

Sapphire, Ruby, or Ceramic Piston Assemblies are manufactured using a proprietary "press fit" or "heat set" process that ensures the tightest piston OD and ferrule ID tolerances in the industry. Most competing products use adhesives to assemble the piston rod into the ferrule, which can impede pump performance. We provide ODs down to ± 0.00001" with surface finishes down to 0.25 microinch (Ra). We offer exclusive grinding and lapping processes for cost effective, quality components in high volumes Custom piston diameters from 0.015" to +2.0".

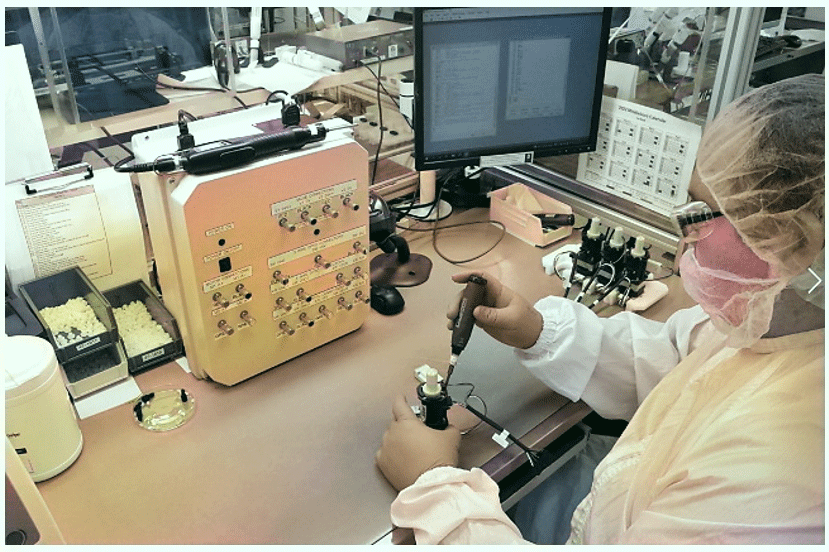

Pump Head Assemblies are precisely machined then combined with check value and seal technology. The complete solution is tested per OEM specifications to ensure accurate flow and sealing pressures. Our custom tubing and fittings are available upon request. Components assembled in class 1,000 and 10,000 clean rooms to ensure optimal performance.

IDEX Health & Science employs a robust, data-driven development process to deliver products tailored for your application. Our careful engineering approach pays attention to more than just the piston, seal, and electromechanical design. We complement our products with extensive testing to ensure reliability and performance.

Testing multiple pump parameters independently, or as part of extensive life test populations, provides you with demonstrated instrument reliability. Our life-test methods use commercially available reagent preparations, or your unique reagent blend to provided confidence in product performance.

Our Manufacturing Operations, Quality, Purchasing, and Planning groups are a part of our development teams and work together to transfer pump specifications into the production environment.

We use documented and controlled ISO 9001:2015 work processes, automated test equipment, and verify the product’s value stream to ensure consistent and high-quality products. This also allows us to control your cost targets throughout the project and during continuous production.

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.