Reduce Fluidic System Complexity with Manifolds

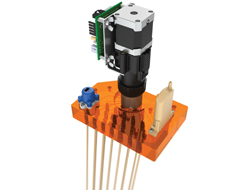

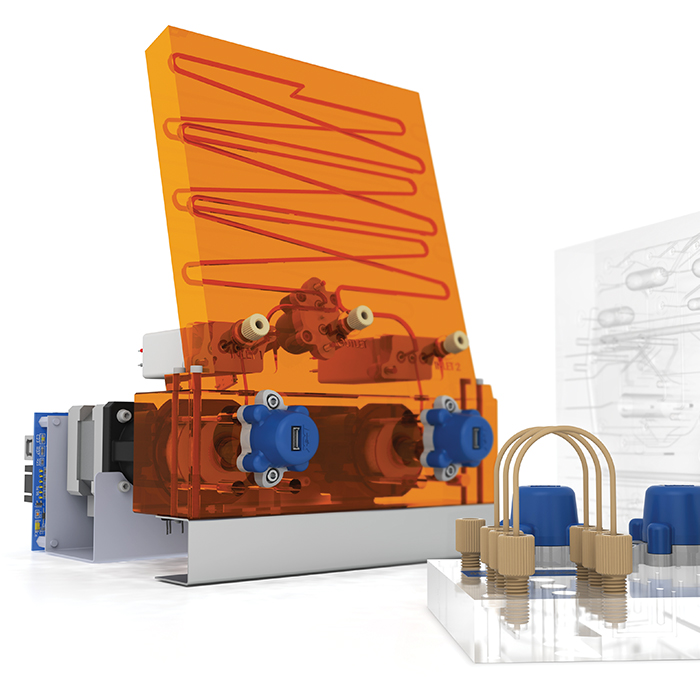

Streamline your complex reagent fluidics flow path with a custom IDEX Health & Science valve manifold. Our design team works with you to develop an optimized manifold for your unique fluidics system. From plastic machined manifolds, diffusion-bonded manifolds, to manifold assemblies— IDEX Health & Science manifolds provide a more reliable, serviceable and consolidated fluid path, instilling confidence in the reliability of your instrument. The design possibilities are endless, with integration including tubing & fittings, probes, valving (rotary and solenoid), pumps, degassers, and sensors.

Considering whether a manifold is right for your flow path? IDEX Health & Science manifolds offer many benefits and capabilities. Contact us today to speak with an expert about your fluidics platform needs.

Benefits of Partnering with IDEX Health & Science for Manifolds

- Consistent fluidic performance in every instrument, every time

- Enhanced system reliability

- Reduced complexity and the number of leak points

- Simplified installation and servicing

- Simplified reagent flow paths by integrating multiple fluidic components into a unified fluidic system

- Completely customizable

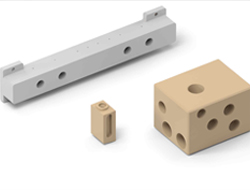

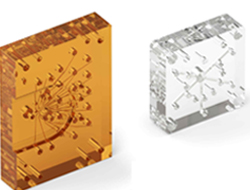

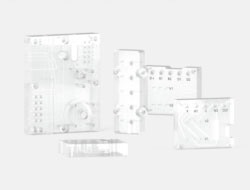

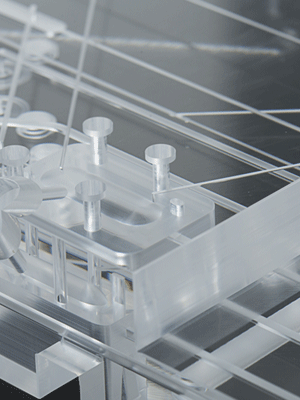

| Bonded Manifolds | Machined Plastic Manifolds | RPM (Rapid Prototype Manifolds) | ||

| Manifold Technology Selection Guidelines | Best fluid flow performance Lowest carryover and unswept volumes Lowest dead volume | Lowest cost manifold solution Offers the broadest range of material options | Best for small volume prototypes to test form, fit and basic function | |

| Typical Use Cases | Complex reagent distribution systems, large reagent count dispense systems, fluidic component integration | Reagent handling, small component mounting (sensors, small pumps), sipper or fluidic device conduit | Rapid prototyping of multi-layer systems for benchmarking performance or multi-design evaluation | |

| Typical Materials | Acrylic (PMMA) | Ultem (PEI) | All Machinable Plastics (Acrylic, PEEK, PSU, POM, PP, Ultem, PVC)* | Proprietary resins |

| Relative Design Advantages | Less expensive, completely transparent | High thermal and material strength | Material is highly customizable, high degree of design flexibility | Fast manufacturing time, same form, fit and function as multi-layered |

| Chemical Compatibility | Good aqueous chemicals and most buffers | Best in class, handles most aqueous reagents | Material dependent** | Resistant to most aqueous compounds, only recommended for prototype use |

| Biological Compatibility | No adverse or secondary interactions observed with the polymers used in manifold manufacturing | |||

| Track Configurations | Curved, Straight, Multi-level 3-D | Straight (Drilled) | Curved, Straight, Multi-level 3-D | |

| Track Cross Sections | Square Track, Round Track, "D" Track*** | Round | Square Track, Round Track, "D" Track*** | |

* Not all plastics may be compatible with part specifications, The IDEX Health and Science engineering team will review the desired materials to determine specification compatibility

** Customer selected materials have a variety of chemical and biocompatibilities, our application scientists will work with your team to ensure biocompatibility with your application

*** Multiple cross-sections available, IDEX Health and Science recommends D-shaped tracks for optimal manufacturing performance, RPM track selection should be the same as the

design intent for production (e.g. round only for a production machined manifold

General Design Considerations:

- Consult our engineering experts at the start of your project for application, design, and DFMA assistance.

- When selecting materials consider fluid compatibility, functional performance requirements, environmental conditions, manufacturability, and cost.

- Reduce part count by integrating as many discrete components on any manifold face that is accessible or a complete assembly replacement that offers “plug and play” modularity.

Typical application pressures less than 100 psi (7 bar)

Type of Manifolds We Offer:

Questions about which machined manifold to use, or ready to get started?

Partner with us for your next custom valve manifold project.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.