Machining of Plastic Manifolds for Life Sciences

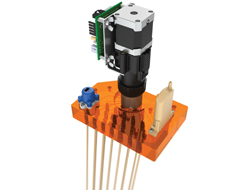

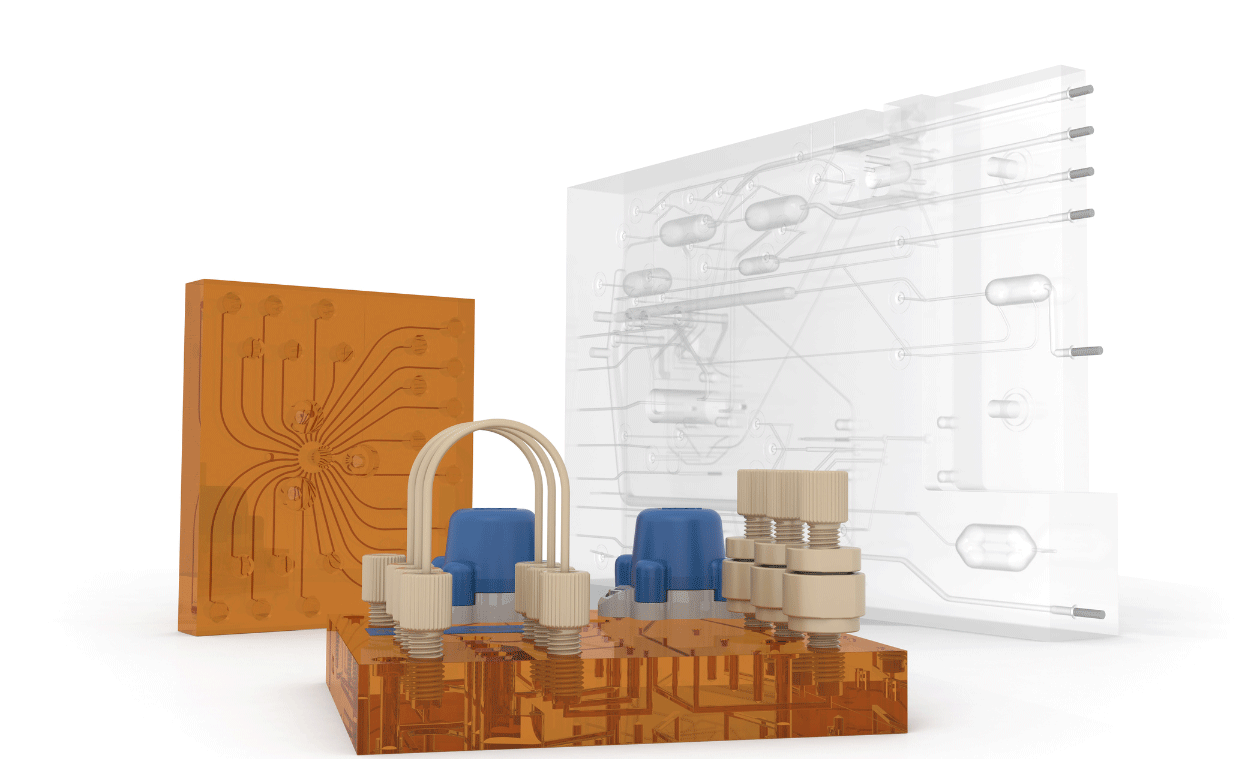

IDEX Health & Science offers high-quality plastic machined components for life science applications and instrumentation. Whether you are looking for a custom cross-drilled component, a larger diffusion bonded manifold, or anything in between, we can create a solution for you. Our quick prototyping and high-precision manufacturing ensure you get your system online without impacting your production schedule.

Available Materials for Plastic Manifolds

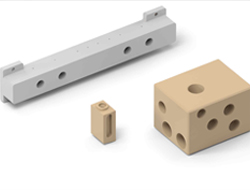

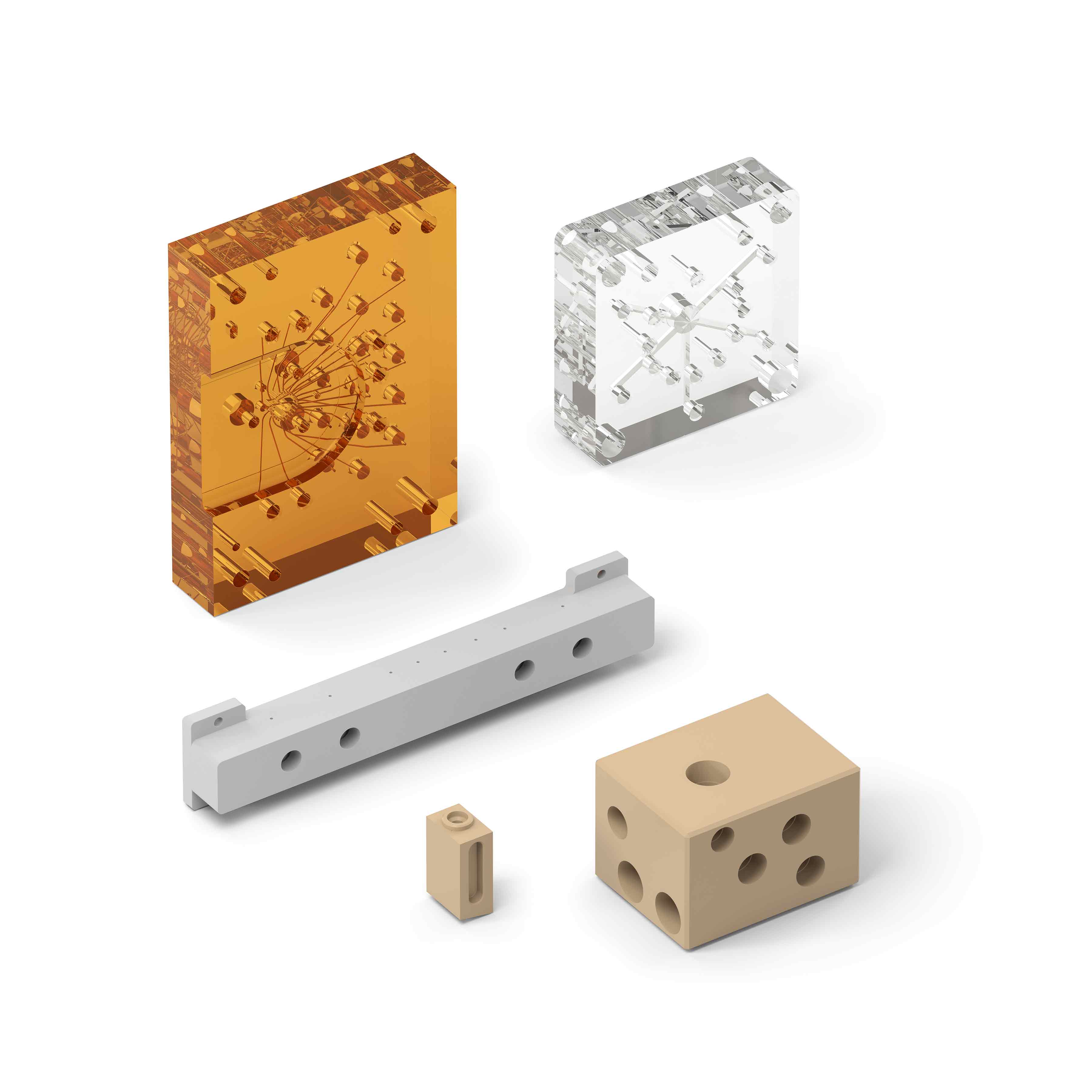

Our machined manifolds can be made from a variety of polymers, including PEEK, PVC, Acrylic, Ultem, etc.

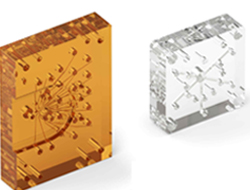

Diffusion bonded manifolds primarily use PMMA (acrylic) for a cost conscious, fully transparent manifold or PEI (Ultem) for applications requiring more aggressive reagents or high-temperature exposure.

Contact us to learn about the best plastic for your fluidic application, and how we can quickly turnaround a solution manifold for you.

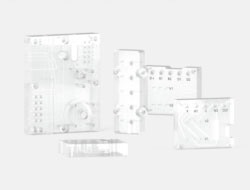

We Offer Several Types of Plastic Machined Manifolds

Key Capabilities & Benefits of Our Plastic Manifolds

With over 60 years of experience making plastic manifolds, we’ve perfected machining and processing.

| Capabilities | Benefits |

|---|---|

| Down to 0.250 mm drilled features and 0.500 mm diameter bonded manifold channels | Efficient consumption of reagents |

| 0.005 mm machining tolerancing 0.125 mm channel tolerances | Consistent fluidic performance in every instrument, every time |

| Square, round, and “D”* channels | Maximize fully swept fluid paths |

| 16 µin channel surface roughness | Minimize reagent carryover and enable channel visibility |

| < 20 µin external surface finish | Pristine surface finish for optical clarity and component sealing |

| 60+ years of DFM experience | Completely customizable & designed for cost savings |

Our Manifolds are Ideal for Life Science Applications

Questions about which machined manifold to use, or ready to get started?

Contact us today to speak with an expert about your fluidics platform needs.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.