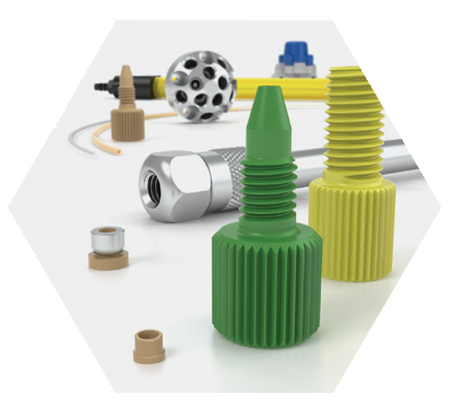

We Enable a Wide Range of Fluidics, from Components through Subassemblies

Whether you’re looking for a single fluidic component or the development of a comprehensive fluidic engine, we can help you manage risk and overall costs across your complete development process. As a component and assembly manufacturer, we utilize innovative collaboration agreements to keep development costs competitive and make experience-based trade-offs to help support our manufacturing partners early in the development process.

Your High Quality Single-Source Partner for the Entire Fluidic Pathway

The accuracy and precision of any instrument in the in vitro diagnostic and biotechnology field is heavily, if not completely, reliant on the tools of the fluidic management system. Our manufacturing facilities utilize the latest technologies to ensure market-leading capabilities. From precision molding and 5-axis CNC automation, to clean assembly and reliable product quality control, IDEX Health & Science possesses a full spectrum of capabilities to fulfill the needs of customized life science and IVD instrumentation.

Having the technology available to meet the precise specifications of our customers is a critical aspect of being an effective partner, but is only one piece of the puzzle. Understanding critical parameters and being able to translate them into manufacturable and scalable solutions is a critical facet that can make or break a platform. IDEX Health & Science R&D engineering works closely with the manufacturing engineering and operations teams from the very beginning of every project to ensure design for manufacturability is considered, from initial conception through full production and platform launch.