Fluidics

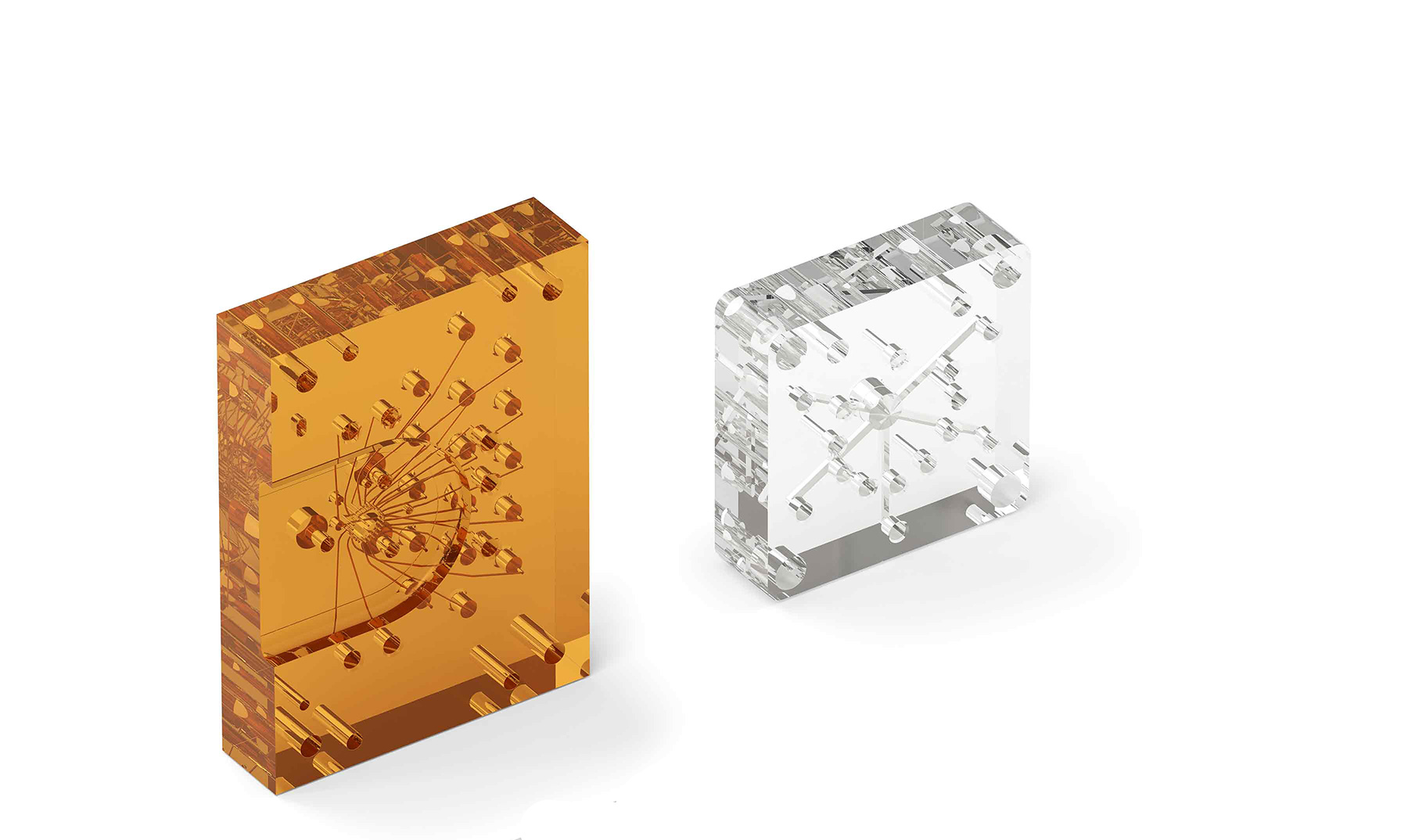

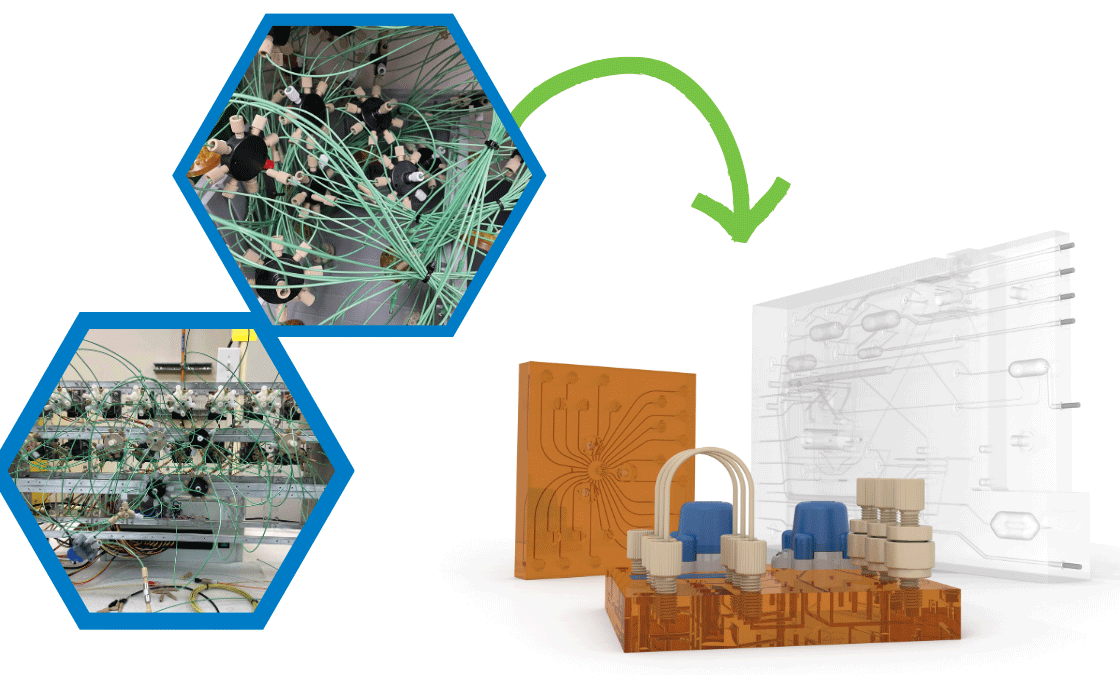

Modern instrumentation involves complex fluidic interactions. Incorporating a diffusion bonded manifold into your design consolidates multiple flow paths into one cohesive unit, simplifying instrument manufacturing and serviceability.

IDEX Health & Science has decades of experience providing customized manifold solutions to the in-vitro diagnostic (IVD), analytical sciences, and life science industry. Our experienced engineering team partners with you to ensure your custom manifold is designed to drive out risk, lower fluidic variability, and reduce total cost of ownership.

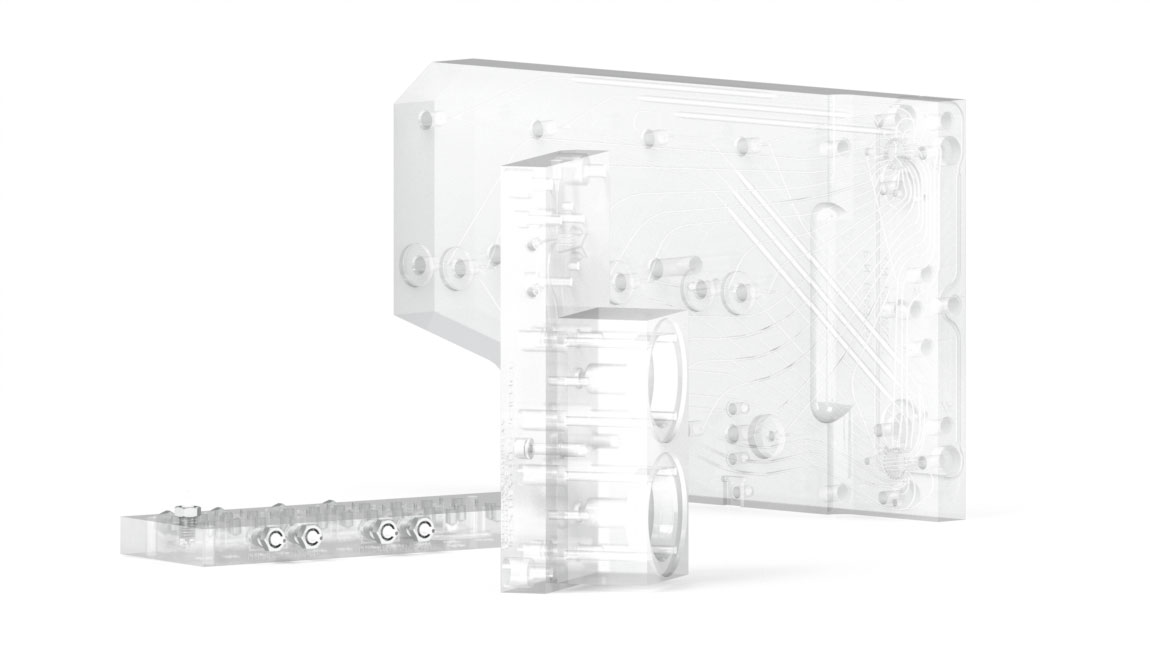

With thorough manufacturing, testing, and inspection protocols we ensure your diffusion bonded manifolds will be robust over the life of your instrument, without worry of variability due to channel deformation, stress points, or delamination.

Partner with us for your next custom manifold project.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

* Multiple cross-sections available, IDEX Health & Science recommends D-shaped tracks for optimal manufacturing performance