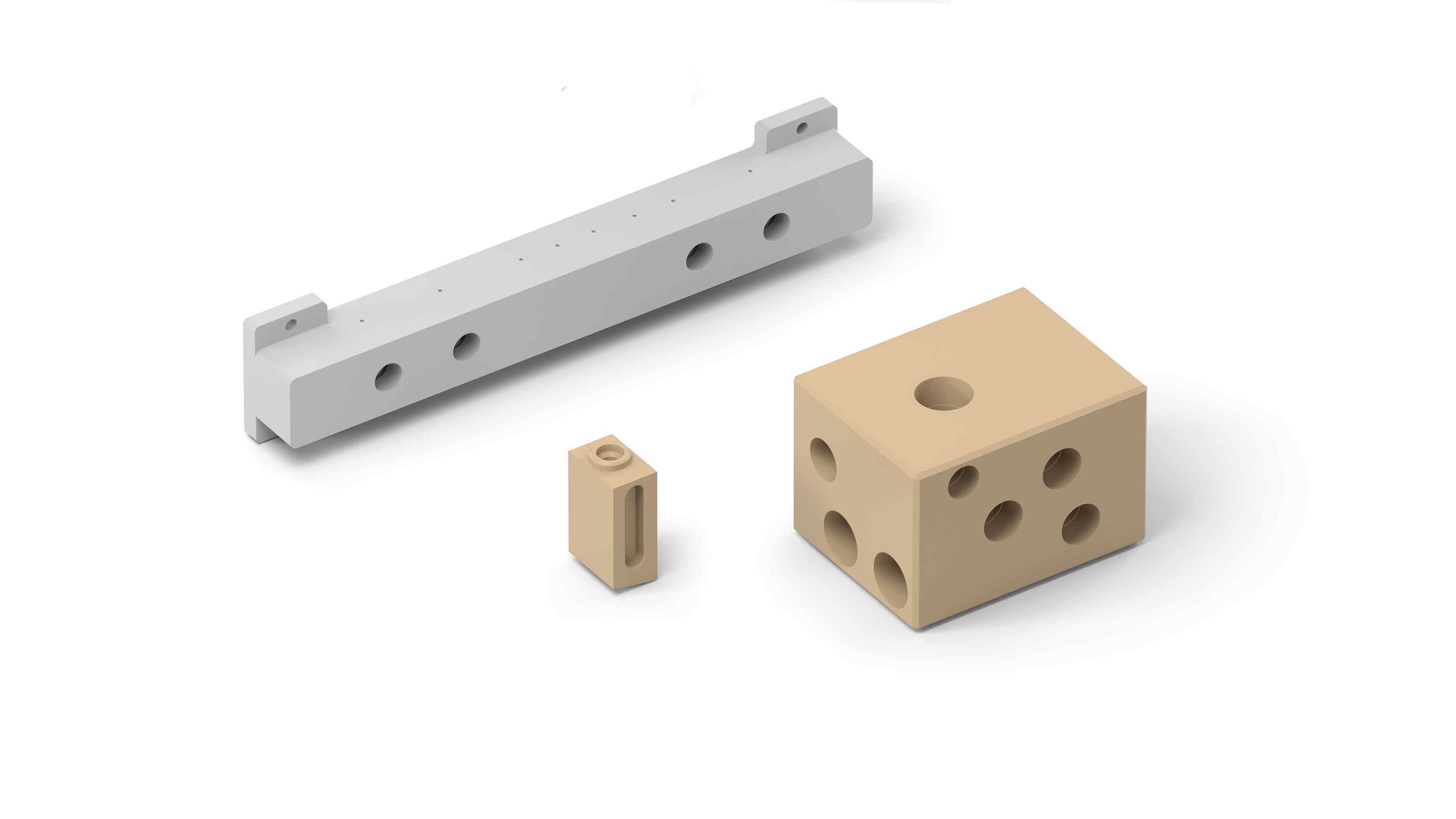

Fluidics

Selecting a vendor for even the smallest component on your instrument can be a complex decision. Partnering with IDEX Health & Science for your machined polymeric components ensures you receive a high-quality part, whether you are designing for a new prototype or replacing a part currently in production.

We offer 5th axis CNC machining, turning, and milling, all with tight tolerances, reproducibly meeting your custom specifications. With a wide range of polymer materials available, we bring your design to life through advanced machining and automated processes governed under a quality driven ISO 9001:2015 certified process.

* Not all plastics may be compatible with part specifications, IDEX Health & Science will review the desired materials to determine specification compatibility

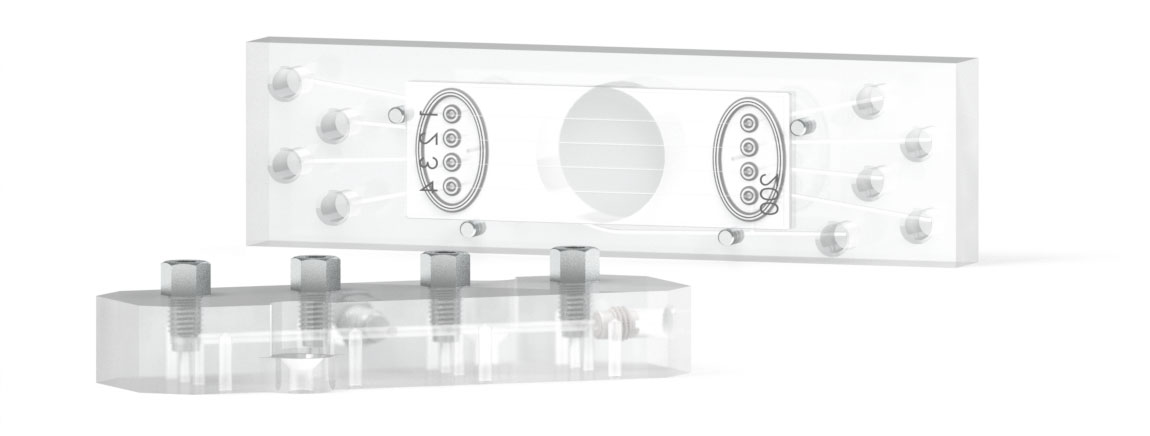

Partner with us for your next custom manifold project.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.