Complete Optofluidic System Solutions for Life Science Instrument Developers

Degassers

The Key to Reliable Fluidic Performance

Variability in sample dispense volumes, noisy optical detection, or system shutdowns due to pressure variations are risks if dissolved gasses are present in your system. Eliminate issues that can cause instrument downtime by incorporating a degasser into your platform. Available in a wide variety of sizes and materials, capable of taming your most challenging fluids, IDEX Health & Science degassers improve instrument reliability and repeatability.

Contact us today to start a conversation about your next life science instrument

*Required Field

Pumps

Avoid Leaks and Maintain Instrument Precision

We have proven experience in manufacturing highly-precise, motorized piston pumps and pump components for the in-vitro diagnostic and life science industry. Backed by rigorous testing, pumps from IDEX Health & Science enable you to achieve higher instrument reliability with less downtime for service. With a wide range of pump volumes and customization options, our pumps help you implement sophisticated fluid delivery protocols and de-risk your development efforts.

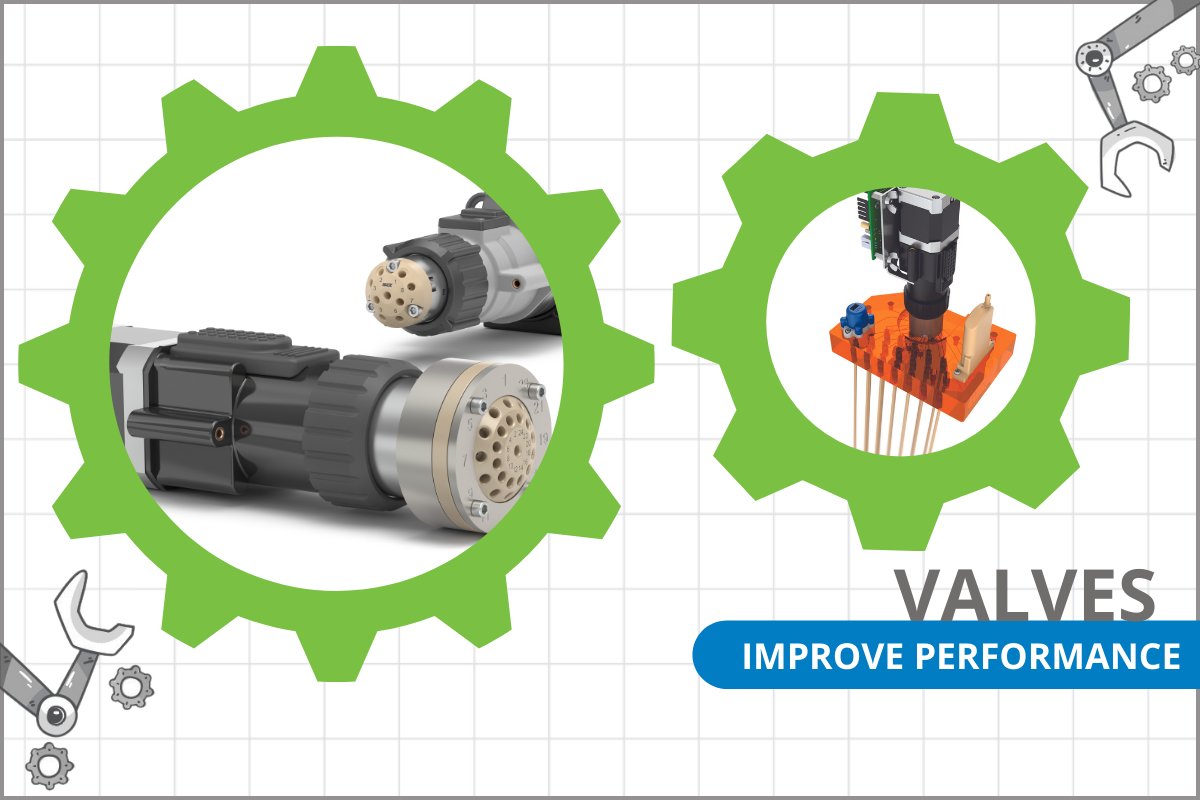

Valves

Simplify Instrument Design While Improving Performance

Streamline your complex reagent flow path with a custom rotary shear valve. Whether you are looking for a sample introduction valve or a reagent selection valve, we have an offering customized to your needs.

Designed for all applications spanning negative pull systems, low pressure systems (10bar / 145 psi), and ultra-high pressures up to 1300bar (18,000psi), our valves provide reliable fluidic introduction and distribution across your platform. With stainless steel, bio-inert (metal free), and manifold-mountable valve options, you have the flexibility to design for your specific system integration.

IDEX Health & Science has over 45 years of experience in rotary shear valves, we work with you to create custom solutions for reagent selection.

Machined and Bonded Manifold Assemblies

Reduce Fluidic System Complexity with Manifolds

Instrument design may begin as a simple sketch on a whiteboard, but how it comes to life will impact reliability and uptime. We are your full partner for all aspects of fluid movement and plastic machining. Whether you are designing a custom wash station, a fluidic junction point, or connecting to an instrument flow cell, we offer a wide range of materials for custom options to ensure system reproducibility while maintaining tight cost control.

Your customized manifold will unify instrument architecture and reduce plumbing complexity, minimize the risk of leak points, and save time during instrument assembly and servicing. With over 60 years of experience in custom polymer machining, learn how IDEX Health & Science can help you design and manufacture a custom solution. .

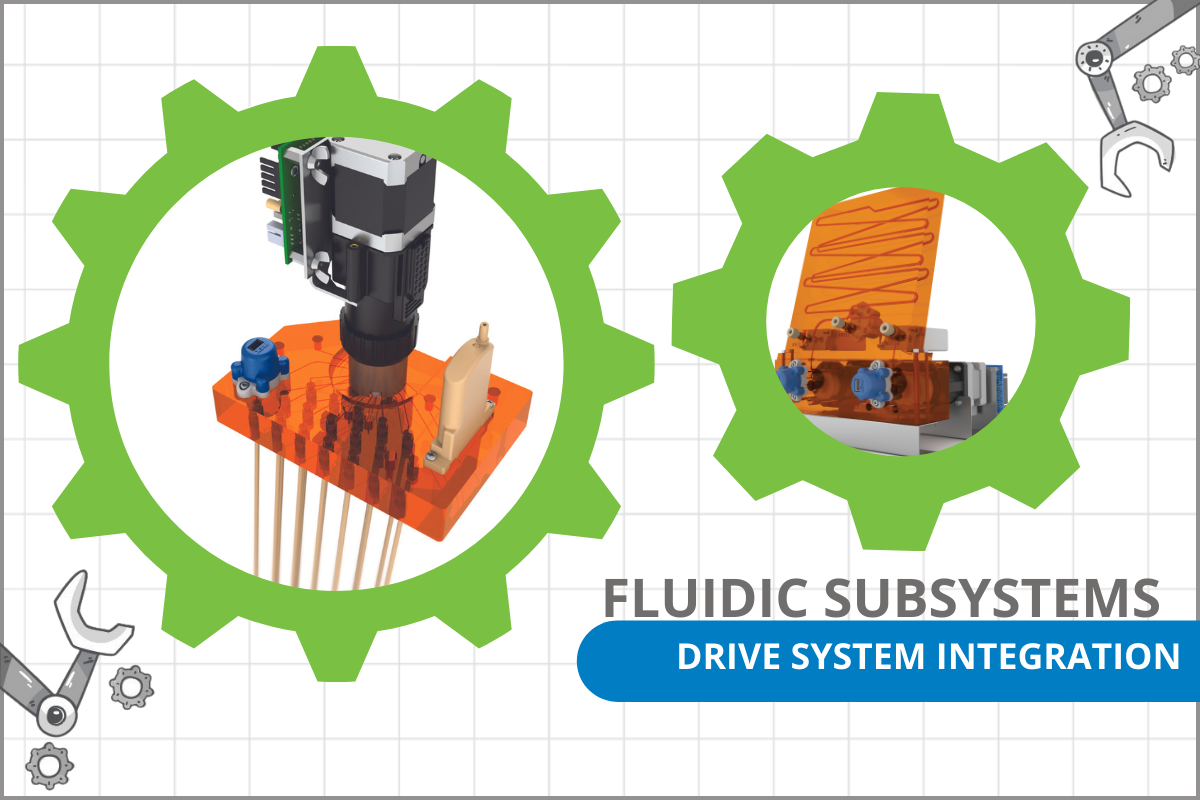

Fluidic Subsystems

Sparking creative Solutions or your complex fluidic architecture

Integrated fluidic subsystems from IDEX Health & Science deliver exceptional instrument performance. Our in-house engineering group works as an extension of your design team. We are your experts in pumps, valves, degassing and tubing assemblies and can help you reduce the fluidic complexity of your platform. Our computational modeling tools look for risk before you build your first breadboard.

IDEX Health & Science’s vertically integrated approach to subsystem design and manufacturing mitigates risk, minimizes cost, and maximizes performance. Learn how we can customize a solution for you offering complete assembly and testing ensure your specific performance requirements are met.

Microfluidics

Solutions That Make Your Ideas Flow

We are proud to be one of the few OEM suppliers with a demonstrated capability to make complex assays work on microfluidic cartridges. From flow cells and droplet generators for genomics to complex sample-to-answer solutions for point-of-care or in-field testing, we are a recognized leader in miniaturizing an entire laboratory setup into a single device —with on-card reagents, pumps, valves, sensors, and optical interfaces.

Tubing Assemblies

Streamline your system manufacturing with custom tubing assemblies

We can help you achieve optimal solutions very quickly, while supporting your development from the start, with an emphasis on manufacturing efficiency and system reliability. When you move towards industrializing your instrument or platform, our engineering experts provide cost-effective tubing assemblies that improve your system’s reliability and uptime with tight connections that stay protected from various thermomechanical loads. We provide unbeatable convenience for the assembly line, too.

Sipper Probes

Control Specifications and Tolerances

Our vertical manufacturing capabilities of polymer probes and assemblies allow us to control specifications and tolerances needed in today’s manifolds. PEEK probes provide the strength required for repetitive use with the benefit of biocompatibility and inertness. Multiple Materials include Polymer PEEK and Stainless Steel options.

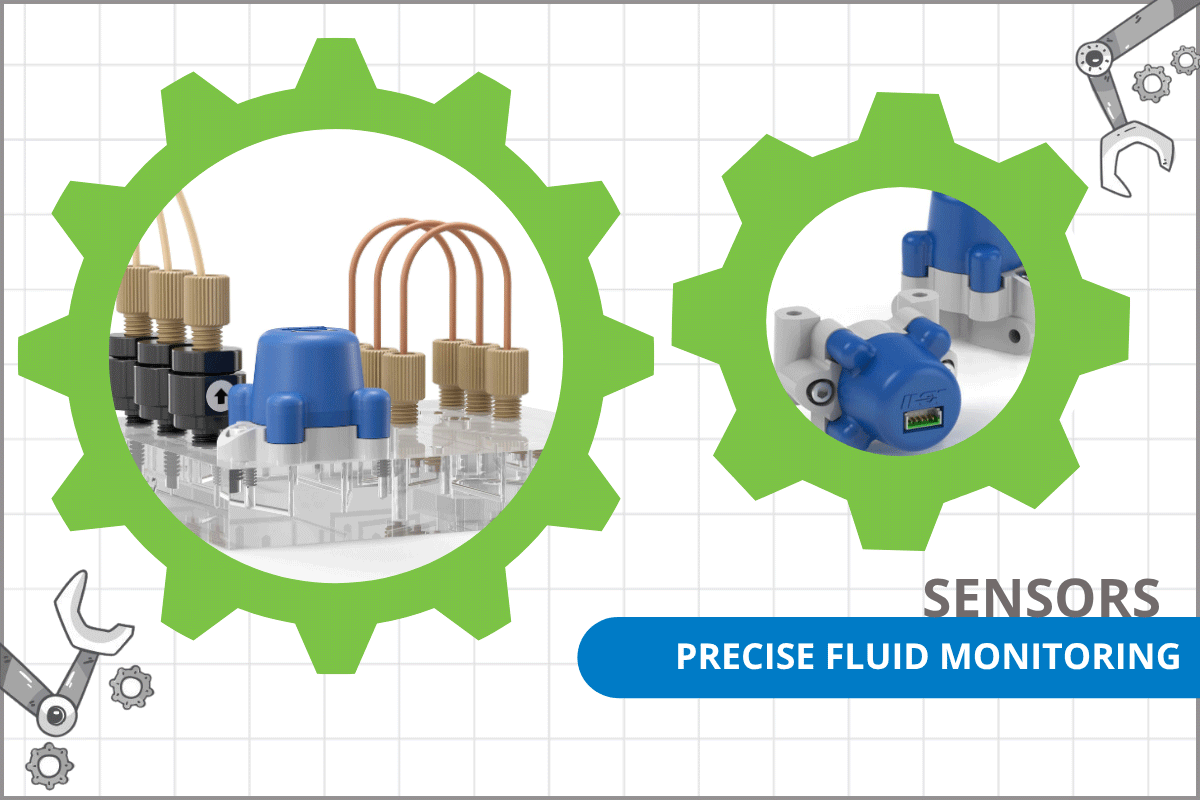

Sensors

Precise, Inline Pressure Sensing

Immediately detect blockages and mitigate risk before important samples are compromised with modular pressure sensors from IDEX Health & Science. The PS200 pressure sensor allows you to continually monitor system pressures for reliable instrument operation up to 200 psi (13bar). The fully isolated MEMS sensing element reacts instantly to pressure changes in your fluidic pathway, offering precise pressure monitoring and tight control over your fluidic operations. Our pressure sensors can be used as a stand-alone implementation or mounted with a manifold for seamless system integration.

Optical Filters

See More with Semrock® Optical Filters

We offer top-tier engineering expertise to optimize your system with Semrock optical filters. Our filters outperform others, enhancing performance with faster measurements, reliability, and reduced component count. At IDEX Health & Science, we ensure consistent high-volume production for our OEM customers, providing tailored solutions from our standard catalog or through custom designs by our expert team.

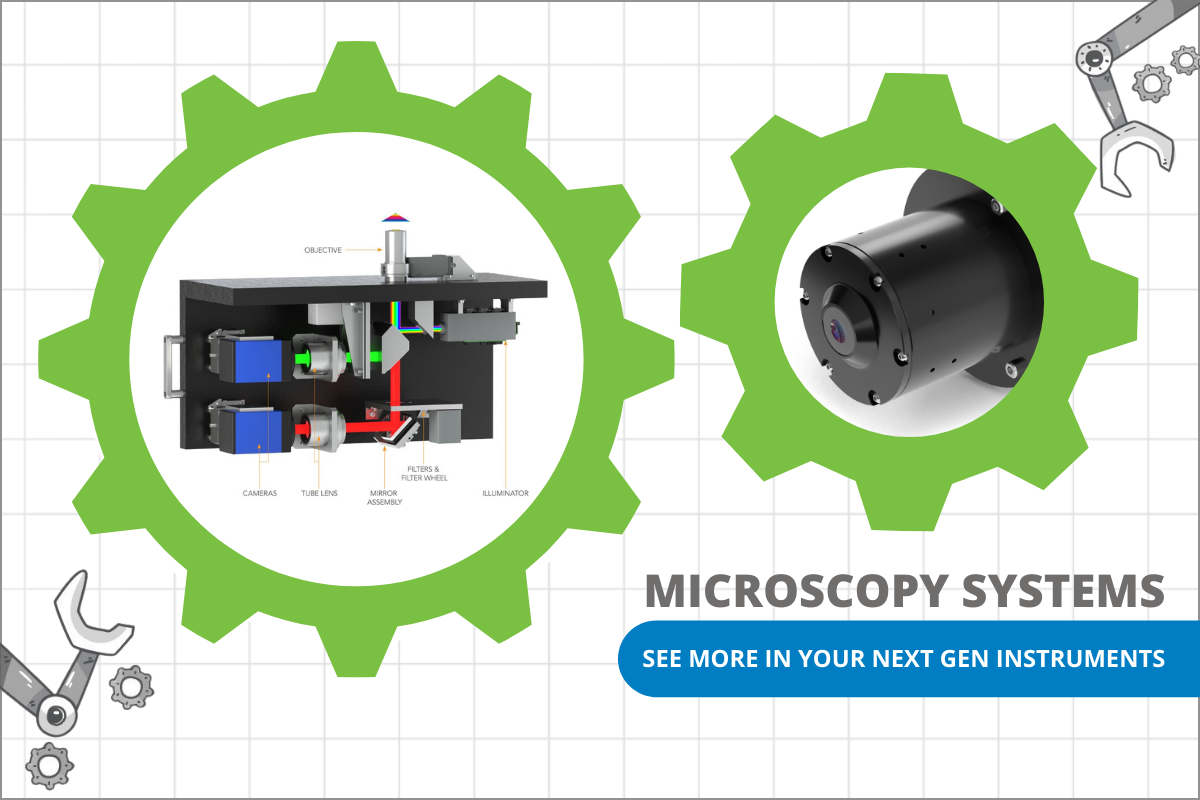

Microscopy Systems

See More in Your Next Gen Instruments

When you need a complete microscopy system at the core of your life science or other high-performance instrument, our expertise in all aspects of optics combined with our proven design-through-manufacturing approach is your solution. Systems engineering always requires trade-offs to be made and these decisions have significant consequences in terms of performance, price, and reliability. This maxim is just as true for a microscopy system — where illumination optics, imaging optics, spectral optics, an autofocus system, a detection system, and all other supporting optical, opto-mechanical, and electronic components required to interface the system to the overall instrument must work flawlessly together time after time. Don’t risk bolting together parts that weren’t designed with one another in mind. Let us design and build a fully integrated system for your instrument.

New Product Feature: Melles® Griot XPLAN™ CCG Lens Series