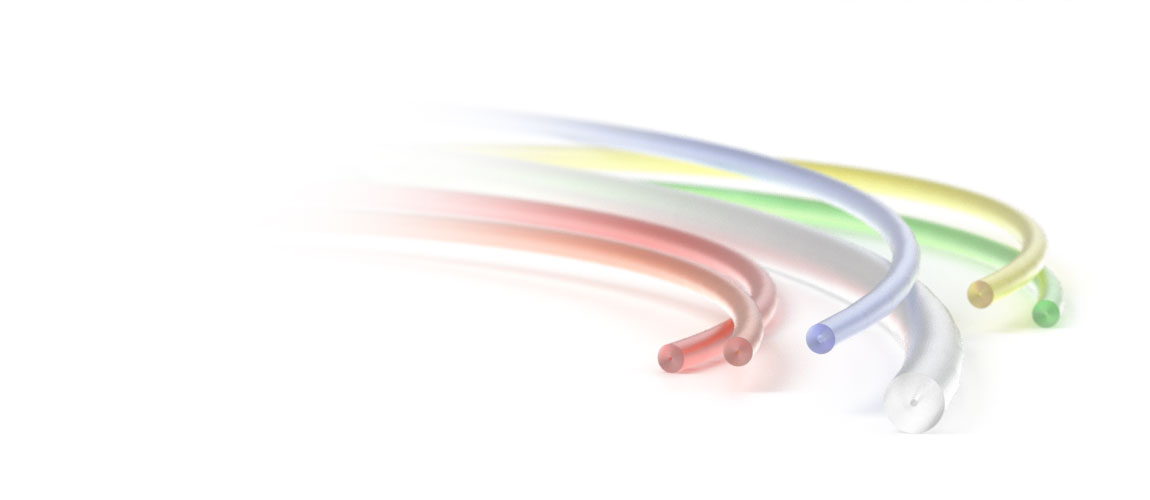

FAQs: FEP Tubing

What is FEP Tubing?

FEP tubing (Fluoroethylenepropylen) is made with a fluorinated ethylene-propylene material. FEP tubing is a copolymer of TFE and can be transparent or in multiple colors for easy identification. It was developed as an alternative to PTFE tubing, which

has limitations..png?sfvrsn=b7cae875_1)

What is FEP Tubing Used For?

FEP tubing is a great inexpensive alternative for applications that need chemical resistance and large temperature exposure including biopharmaceutical, and laboratory applications, and it’s also ideal for low-pressure applications.

What is the Difference Between PTFE and FEP Tubing?

FEP tubing is essentially the melt-processable version of PTFE tubing. While FEP has similar properties to PTFE, it has a lower maximum operating temperature of +200°C. The main benefit of using FEP tubing is that it can be more easily cut and formed.

Is FEP Tubing Flexible?

FEP tubing can be easily cut, formed, and re-molded. Its flexibility and compatibility with push-to-connect fittings also make it easy to install.

Learn About Our FEP Tubing Capabilities

Related Resources and Products