Is Your Flow Path Aligned?

Streamline Your Higher-End Applications with Custom Rotary Shear Valves

Understanding the specifics of fluid flow through a valve becomes increasingly crucial as passage sizes in the valves get smaller. Smaller flow passages are more difficult to align correctly and if misaligned can contribute to degraded chromatography and poor system performance.

Challenges of Misaligned Flow Paths:

- Poor flow in valves can contribute to degraded chromatography and poor system performance.

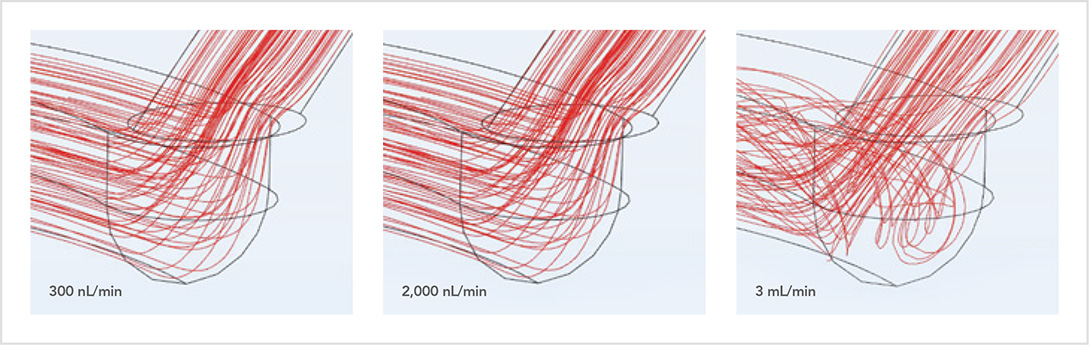

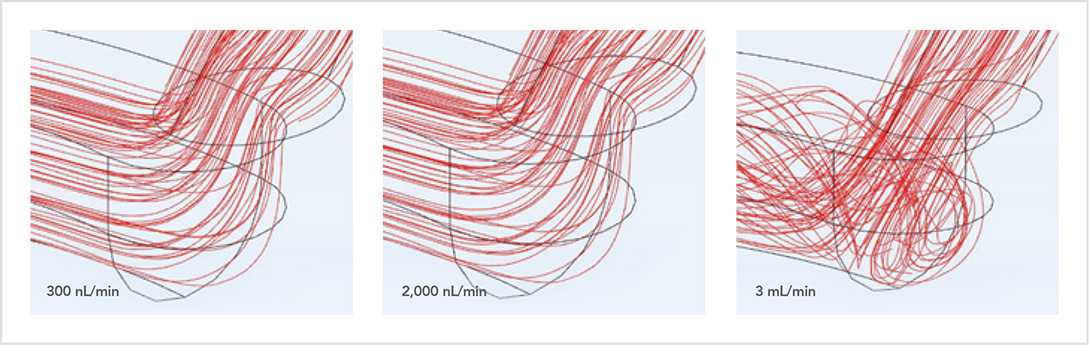

- Turbulence in the flow can arise from sufficiently large misalignments and flow rates (refer to figures 3-5).

- Fluid velocities in valves will differ for different passage sizes and different degrees of misalignment resulting in mixed results and varying misalignments.

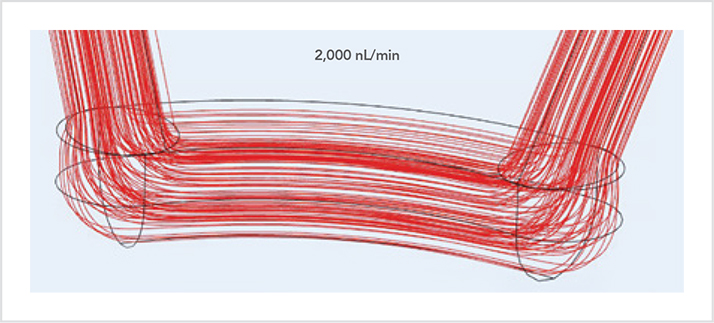

We prepared the below examples of streamlines and slice velocity plots with a flow path through a valve. Simulations were run with flow rates of 300 nL/min, 2,000 nL/min, and 3.0 mL/min:

Figure 3: Streamlines with Nominal Alignment

Figure 4: Streamlines at 0.002” (0.05mm) Misalignment

Figure 5: Streamlines at 0.005” (0.13mm) Misalignment

Solution:

IDEX Health & Science uses Computational Fluid Dynamics (CFD) simulations to evaluate and optimize valve designs virtually before the first parts are manufactured. By leveraging CFD simulations and analysis equipment we can:

- Maintain as smooth a flow as possible to reduce unwanted analyte diffusion and mixing to avoid reducing chromatographic quality.

- Regardless of passage sizes, our simulation method will confirm the effects of misalignment at different flow rates.

- Balance cost, delivery, and design for optimized flow path alignment and tolerancing with special attention paid to fluid flow impact.

The result is a custom valve that will give you a seamless flow path. Along with CFD testing, our team of Engineers, Scientists, and Technicians use tools including FMEA, CFD, FEA, DFX, Tolerance Analysis, DOE, and Weibull-based lifetime demonstration testing.

Partner with us to offer the highest value, shortest lead-time design considering material, design, manufacturability, and reliability for your custom rotary valve project.