PEEKsil Tubing

Key Benefits of PEEKsil Tubing

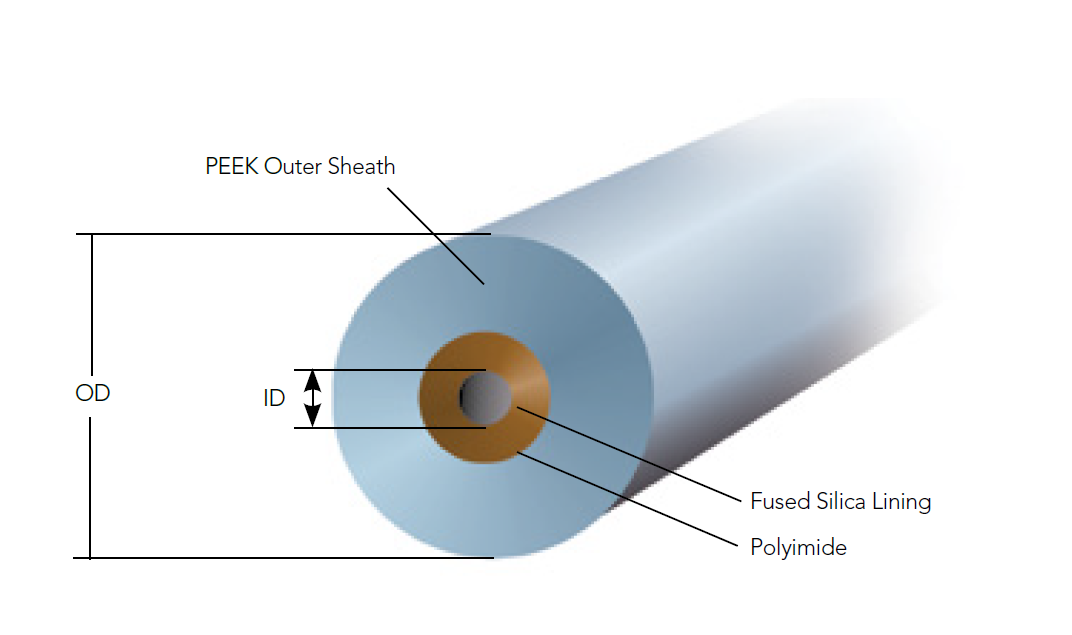

- PEEK covered fused silica

- 1/32” and 1/16” outside diameters with a wide variety of inside diameters

- Precut to numerous standard lengths

PEEKsil’s sheathing is mechanically strong and has ideal characteristics for sealing with many styles of fittings. The fused silica core provides a consistent and rigid fluid pathway with very tight tolerances and industry-accepted chemical properties.

Together, this makes PEEKsil tubing ideal for numerous applications. In fact, PEEKsil can be used as a direct replacement for conventional stainless steel or PEEK tubing in many analytical systems.

Like traditional fused silica tubing, PEEKsil has excellent chemical compatibility and extremely low adsorption characteristics, especially when compared with stainless steel.

Please Note: Do not cut this tubing. It should be used at its precut lengths because of permanent damage caused by conventional cutters.

Specifications and Details

| Tubing OD | OD Tolerance | Tubing ID | ID Tolerances |

|---|---|---|---|

| 25 μm | ±0.00004” (1 μm) | ||

| 1/32” | ±0.0008” (20 μm) | 50–100 μm | ±0.00012” (3 μm) |

| 1/16” | ±0.0012” (30 μm) | 0.15–0.30 mm | ±0.0002” (5 μm) |

Because PEEKsil tubing has fused silica tubing at its core, the pressure rating for this tubing is determined by the inner diameter of the tubing. The following chart highlights the Maximum Pressure values for this tubing.

| Tubing ID | Maximum Pressure |

|---|---|

| 25 μm | 25,000 psi (1,723 bar) |

| 50 μm | 20,000 psi (1,379 bar) |

| 75–100 μm | 15,000 psi (1,034 bar) |

| 150–175 μm | 8,500 psi (586 bar) |

| 200–300 μm | 6,000 psi (414 bar) |

The pressure ratings provided are indicative of the performance capabilities of the tubing. The actual pressure limits achievable will depend upon the fittings used, the quality of the receiving port, and other factors. Contact IDEX Health & Science or your authorized Distributor for more information.

Related Products

Other tubing materials and dimensions are available, including FEP, PFA, and PEEK tubing.