Custom Microscope Objective Case Study

Why Consider a Custom Objective?

Most microscope objectives available and in use today were not designed for a specific application. They are generally optimized for best performance at the center of the field of view (FOV), and color correction is either limited or enhanced over a broad wavelength range in the most expensive objectives. And they are generally not manufactured to meet today’s demanding instrument repeatability requirements. By choosing a Melles Griot custom objective solution from IDEX Health & Science, you will experience:

- High-NA, wide-FOV, diffraction-limited resolution performance

- Outstanding wavefront, color and distortion correction over the entire

- FOV Customization for your optical and physical requirements, including telecentricity, laser damage threshold and thermal sensitivity

- Superior repeatability and guaranteed performance from prototype through high-volume production

- Full flexibility and control over your overall system design

Case Study

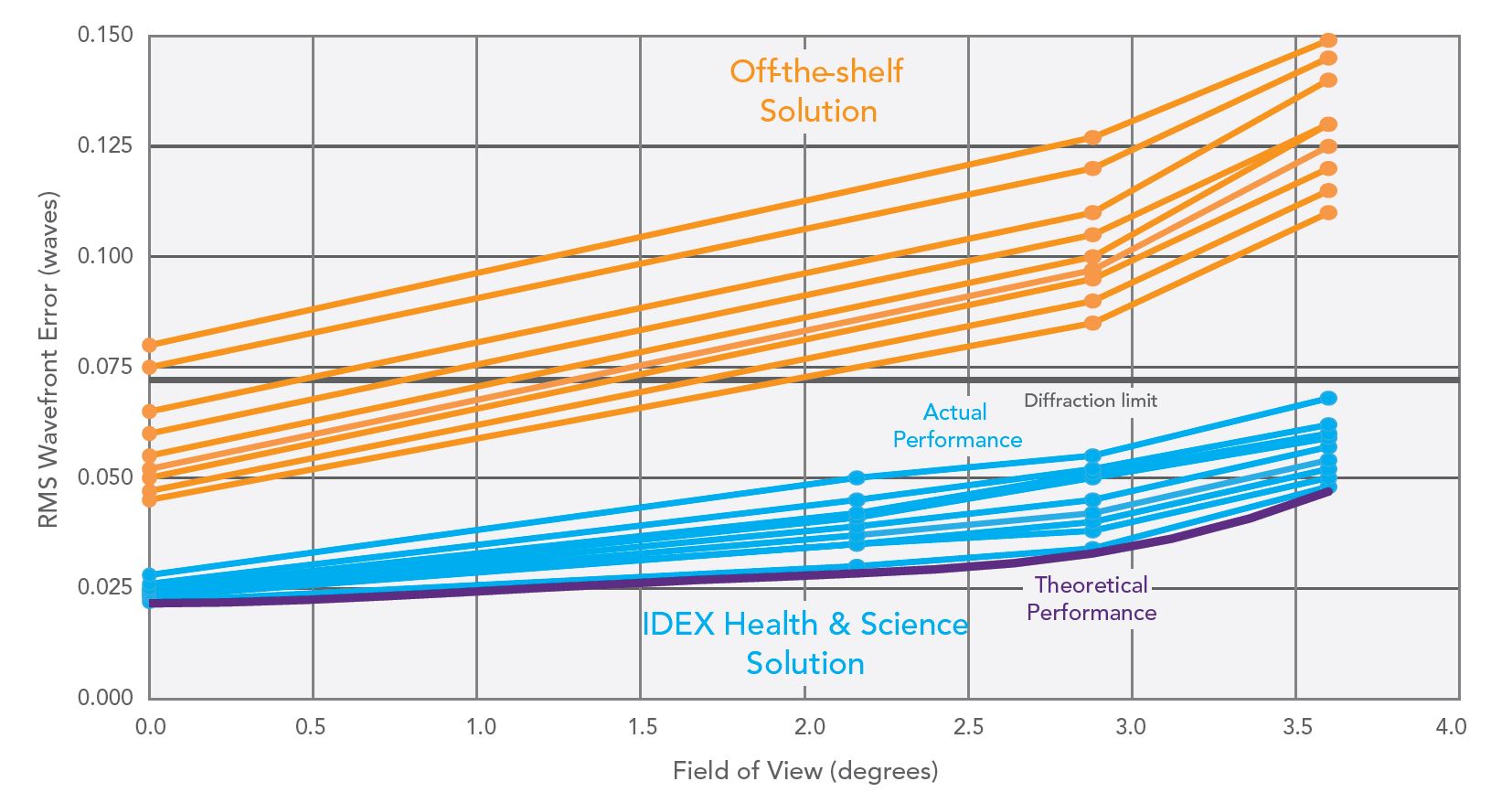

The current generation of one OEM customer’s instrument was based on a commercial high-performance 20X/0.75NA PlanApochromat objective. But this objective could not satisfy the next-generation instrument requirements due to insufficient resolution and color correction over the full FOV, as well as high variability, spatial distortion, and thermal sensitivity (see orange data in graph below).

Caption: IDEX Health & Science | Melles Griot custom-tailored solutions offer superior wavefront correction over the whole imaging field

Custom Objectives to Meet Customer Demands

Our team collaborated closely with this customer’s development team to create a unique objective solution, complete with custom tube lens. This solution achieves diffraction-limited, vignetting-free and extra low-distortion performance over two broad wavelength bands, a wide temperature range, and the entire FOV. And because it was designed specifically for our vertically integrated, volume manufacturing capabilities, this performance is obtained with high yield and guaranteed with extensive testing. The result: the customer’s next-generation instrument is able to meet all of their target market requirements for higher accuracy, throughput, and reliability.

Custom Objective Examples

The following table lists some examples of custom high-performance objectives we have recently designed, developed, and delivered for our customers’ production. Let us craft the most optimal solution for your application.

- Our custom objective designs create differentiation by ultimately reducing overall system complexity while significantly improving performance of the entire system

- Proven track record of taken the most challenging projects and successfully delivering from concept to volume production

| Numerical Aperature | Immersion Medium | Wavelength Range | Specimen FOV (mm) | Working Distance (mm) |

| 0.500 | Air | 530 - 750 | 3.20 | 3.20 |

| 0.750 | Air | 480 - 650 | 1.20 | 1.20 |

| 0.900 | Air | 545 - 770 | 0.46 | 0.46 |

| 0.900 | Air | 680 - 950 | 0.46 | 0.46 |

| 0.900 | Air | 470 - 650 | 1.10 | 1.10 |

| 0.950 | Solid | 780 - 790 | 0.19 | 0.19 |

| 0.950 | Solid | 950 - 2000 | 0.20 | 0.20 |

| 0.950 | Solid | 574 - 580 | 0.20 | 0.20 |

| 0.950 | Solid | 1050 - 1600 | 0.21 | 0.21 |

| 0.825 | Water | 505 - 705 | 1.10 | 1.10 |

| 0.825 | Water | 505 - 820 | 1.10 | 1.10 |

| 1.100 | Water | 505 - 820 | 0.72 | 0.72 |

Get the Exact Imaging Performance You Need

Finding it difficult to select the appropriate microscope objective for your application? Observing imaging errors at the edges of your field of view or intolerable chromatic aberration? Can’t precisely quantify or model the performance of available off-the-shelf objectives? Stop compromising! We are happy to work with you to provide a cost-competitive custom microscope objective solution that is ideally suited to your specific application. We guarantee superior imaging performance and repeatability in volume production.

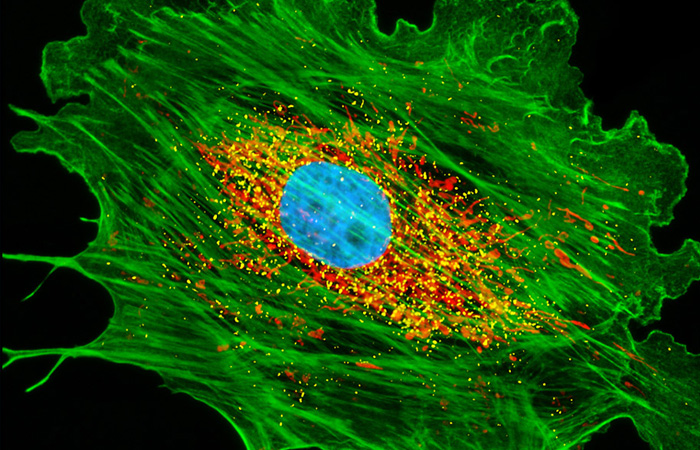

IDEX Health & Science has over forty years of experience developing and manufacturing fully customized high-performance optical systems through our Melles Griot product lines. We have crafted optimal solutions for the most demanding applications ranging from semiconductor inspection and metrology to high-throughput subcellular imaging in life science and medical instrumentation. We routinely produce high-NA, diffraction-limited objectives from the ultraviolet to the infrared. By working closely with your team throughout the full development process—from concept to launch—we enable you to realize a competitive advantage resulting from accelerated time to market, competitive cost, highest quality, and ultimately better product performance.