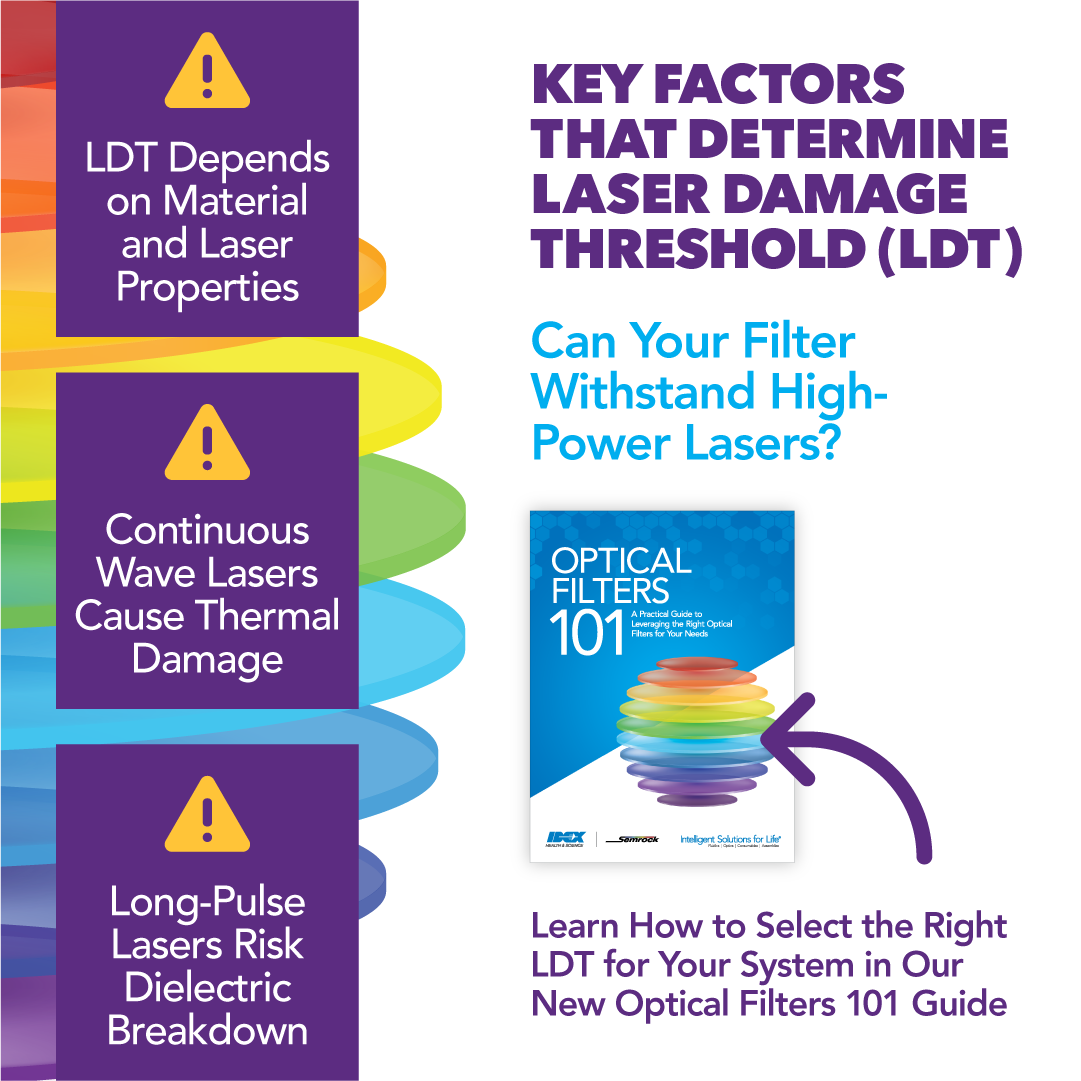

Key Factors That Determine Laser Damage Threshold (LDT)

Laser damage to optical filters is strongly dependent on many factors, and thus it is difficult to guarantee the performance of a filter in all possible circumstances. LDT is typically specified in units of Joules/cm2. Factors important to determining LDT include:

Material properties of the filter, such as:

- Absorption coefficient

- Specific heat

- Melting temperature

- Defects and impurities

- Thickness

- Surface morphology

Laser beam properties, such as:

- Beam size

- Wavelength

- Pulse length

- Repetition rate or duty cycle

- Peak power

Learn More about Laser Damage Threshold

For continuous wave (cw) lasers, Semrock filters have a LDTcw on the order of 10 J/cm2 or higher. Damage by cw lasers is mostly thermal in nature. Very fast pulsed lasers (picosecond-femtosecond pulses) can be treated as “quasi-cw lasers.” The pulse and repetition rates are so fast that the filter materials have no time to relax before the next pulse. The average power density can be used to estimate LDT.

For long-pulse (nanosecond-microsecond pulse length) lasers with repetition rates of 1–100 Hz, dielectric breakdown is the primary damage mechanism. Most Semrock filters have LDTLP values on the order of 1 J/cm2, and are thus considered “high-power laser quality” components. An important exception is the narrowband laser-line filter in which the internal field strength is strongly concentrated in a few layers of the thin-film coating, resulting in an LDTLP that is about an order of magnitude smaller.

When to Use

We have developed an online tool for our customers to estimate the likelihood of laser damage: try it here.

If it appears that laser damage may be a problem in your system, please specify LDT for your filters. Note that LDT measurements are not performed in house and will add time and cost to your order.

Specification Includes:

Laser properties mentioned above