Simple, Cross-Drilled Plastic Manifolds on a Tight Timeline

When you’re developing an instrument with fluidic architecture, precision is paramount. Crafting a seamless flow path requires careful consideration of every detail. The fear of a poorly designed unit can be daunting– potential leaks, inefficiencies, and failures in the field are roadblocks you can't ignore. When faced with these challenges, trust our experts to deliver the solution your instrument needs– a simple, cross-drilled plastic manifold on a tight timeline ensures precision and reliability every step of the way.

IDEX Health & Science, we are experts in precision-machined plastics for life science instrumentation. While you may know us for more complex manifolds, we also quickly produce prototypes for smaller-footprint manifolds with our highly automated machining centers. Our expertise and technology guarantee precision and quality features with cost efficiency in mind.

Design Expertise with a DFM and DFC Focus

With over 60 years of manifold design expertise, you can trust our experts to design your manifolds with a focus on Design for Manufacturing and Design for Cost approach.

Rapid Prototyping

Equipped with precision 3D printing capabilities and a dedicated prototype CNC machining cell, IDEX Health & Science expedites the evaluation of manifolds. Our accelerated process ensures a more rapid delivery than the industry standard timeframe.

High Quality, Precision Manifolds

Enabled by our advanced CNC machining technologies, we consistently manufacture precision manifolds from a variety of polymers, with tolerances down to five microns.

ISO 9001 Certified

We are ISO 9001 certified, guaranteeing the highest quality manifolds with the highest quality standards and repeatable performance.

On-time Delivery

Backed by our extensive manufacturing technologies and expertise, we ensure a smooth ramp-up for high-volume manifolds, consistently delivering on time without challenging your budget.

As your fluidic platform gets more complex, we adapt and grow with you. Our capabilities extend to integrating valves, degassers, sensors, pumps, and connections into your fluidic instrument. Collaboratively, we scale from simple cross-drilled plastic components to intricate bonded manifolds and full-fluidic subsystem assemblies that are fully assembled and tested to your specifications.

Handling everything from large to small, simple to complex, we're your full capability partner for fluidic distribution. Our efficient process ensures high-quality cross-drilled plastic manifolds from prototype to production, so you can focus on the chemistry while we handle everything else.

Learn how partnering with us helps you minimize instrument risk and provide precision manifolds with consistent on-time delivery at a price that won’t challenge your platform.

Key Capabilities & Benefits of Our Plastic Manifolds

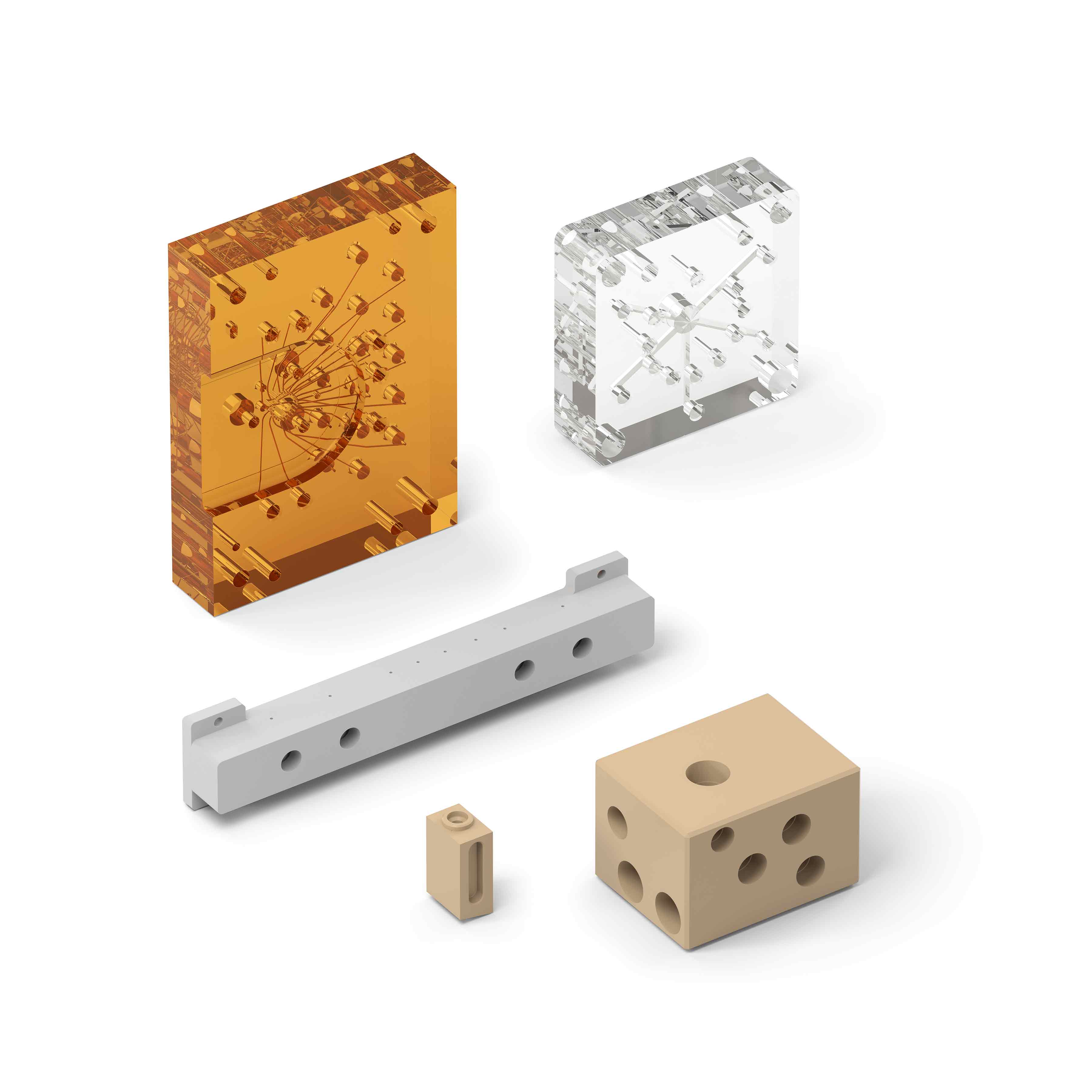

| Bonded Manifolds | Machined Plastic Manifolds | RPM (Rapid Prototype Manifolds) | ||

| Manifold Technology Selection Guidelines | Best fluid flow performance Lowest carryover and unswept volumes Lowest dead volume | Lowest cost manifold solution Offers the broadest range of material options | Best for small volume prototypes to test form, fit and basic function | |

| Typical Use Cases | Complex reagent distribution systems, large reagent count dispense systems, fluidic component integration | Reagent handling, small component mounting (sensors, small pumps), sipper or fluidic device conduit | Rapid prototyping of multi-layer systems for benchmarking performance or multi-design evaluation | |

| Typical Materials | Acrylic (PMMA) | Ultem (PEI) | All Machinable Plastics (Acrylic, PEEK, PSU, POM, PP, Ultem, PVC)* | Proprietary resins |

| Relative Design Advantages | Less expensive, completely transparent | High thermal and material strength | Material is highly customizable, high degree of design flexibility | Fast manufacturing time, same form, fit and function as multi-layered |

| Chemical Compatibility | Good aqueous chemicals and most buffers | Best in class, handles most aqueous reagents | Material dependent** | Resistant to most aqueous compounds, only recommended for prototype use |

| Biological Compatibility | No adverse or secondary interactions observed with the polymers used in manifold manufacturing | |||

| Track Configurations | Curved, Straight, Multi-level 3-D | Straight (Drilled) | Curved, Straight, Multi-level 3-D | |

| Track Cross Sections | Square Track, Round Track, "D" Track*** | Round | Square Track, Round Track, "D" Track*** | |

Partner with us for your next custom cross-drilled manifold project