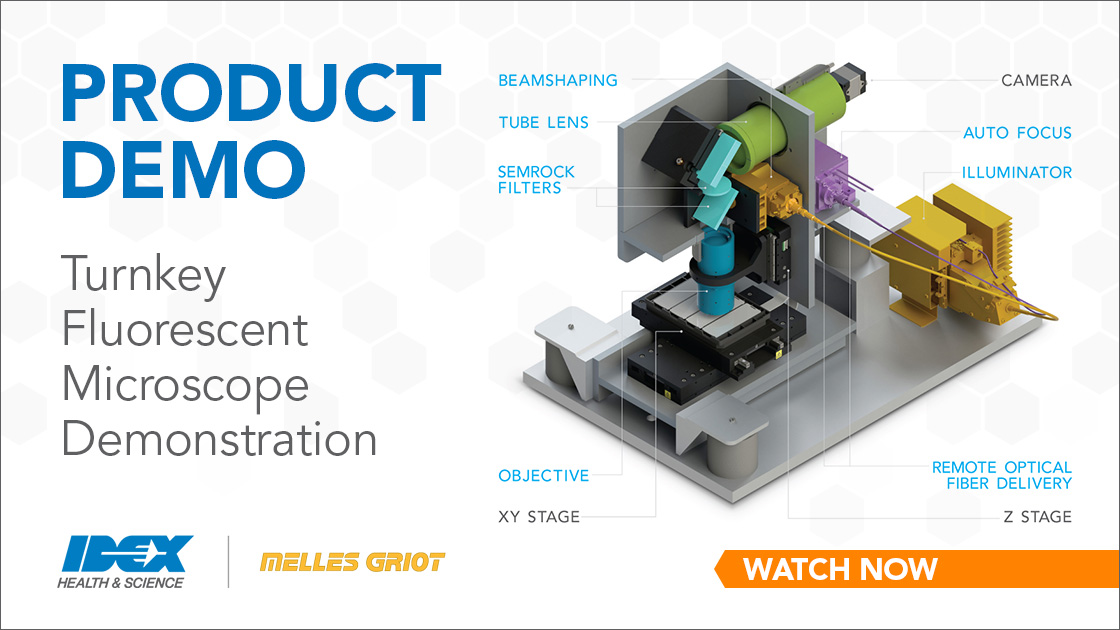

Melles Griot Optical Systems

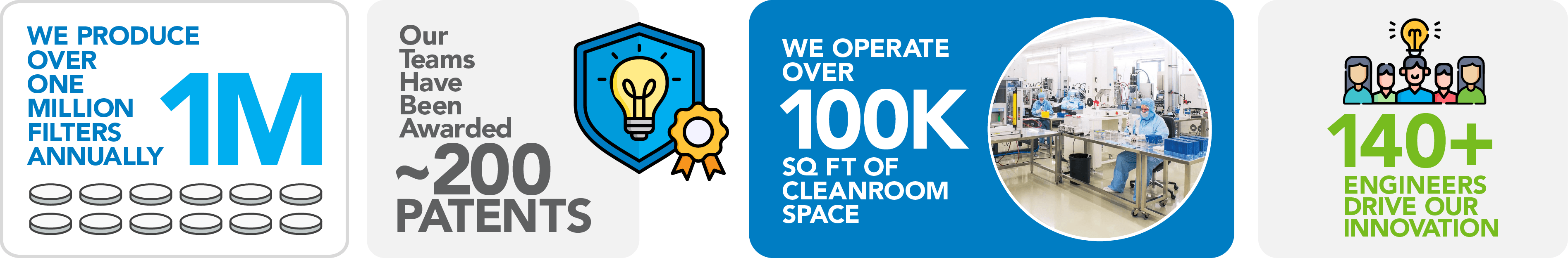

Powering high-throughput imaging from industrial to clinical diagnostic applications. We provide everything from quick-turn breadboard components to fully integrated optical systems, leveraging our 100,000 sq. ft. state-of-the-art facility to accelerate your discovery and scale production.