Key Specifications for Custom Microscope Objective Lenses

Introduction

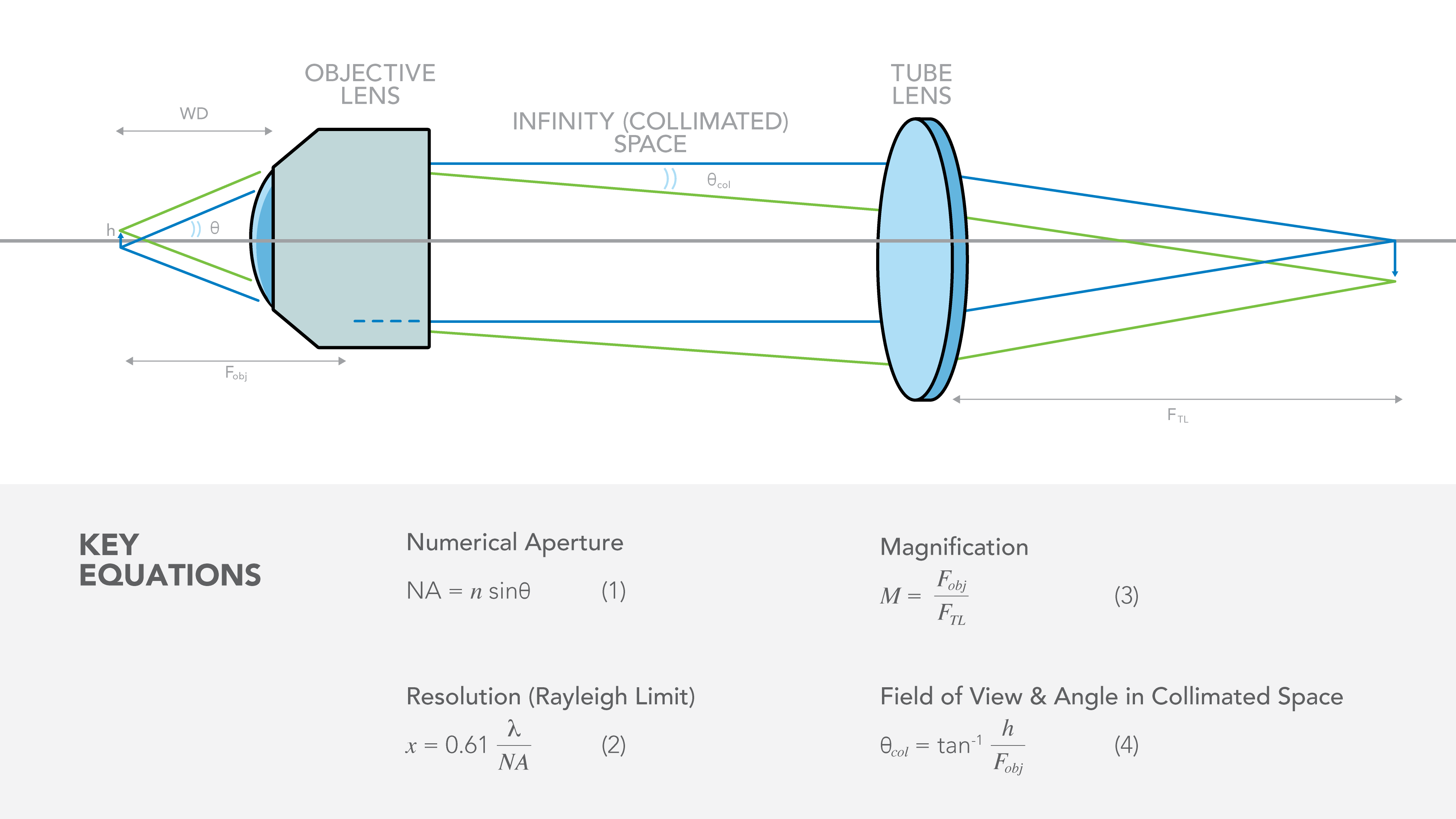

An objective lens is a critical component of a microscope which magnifies the field of view (FOV) and determines the optical resolution of the image. These multi-lens assemblies are aligned with very high accuracy to achieve resolution at or near the diffraction-limit. Modern fluorescence microscopes employ infinity-corrected objective lenses that are designed to be used with a tube lens which focuses light onto the detector (Figure 1). The microscope objective lens is designed to create a collimated region inside the system (infinity space) where designers can easily add filters, mirrors, and other optics. The infinity space can also be used to introduce illumination into the optical path (epi-illumination). Melles Griot optical systems from IDEX Health & Science specialize in the design of custom, high-performance objective lenses and tube lenses, specifically for high-throughput applications which require both high resolution and large FOV. For customers requiring a fast, cost-effective solution for their high-throughput microscope, we offer several off-the-shelf objective and tube lens combinations designed to match common sensor formats. This article reviews the key specifications to address when considering the design of a custom objective lens. Our experienced optical engineers will help refine the specifications to match your performance requirements and budget.

Figure 1: A layout for a microscopy system using an infinity-corrected objective lens and tube lens with common equations. Labels are explained in the text.

Optical Specifications for Objective Lenses:

Numerical Aperture (NA) and Resolution

Numerical Aperture (NA) describes the cone of light that is collected by the objective lens. In eq. 1, q is the angle between the marginal ray and the optical axis (Figure 1). As the optical designer increases the NA of the objective lens, a marginal ray with a larger angle can be collected, thereby increasing the resolving power of the lens (eq. 2). This allows the objective lens to resolve smaller features or more tightly packed objects. As shown in eq. 1, the refractive index of the media (n) impacts the NA. n is equal to 1 in air, but can be higher if the lens is to be used with immersion (usually water or oil). Additionally, the resolution achievable for a diffraction-limited lens is impacted by the wavelength of light (λ) used for imaging. Of course, resolution of the objective lens can be limited by optical aberrations if the lens design or manufacture does not maintain the resolution achievable by diffraction. (see section on aberrations)

In addition to resolution, the NA defines the collection-efficiency of the lens. For an isotropic emitter, the collection efficiency is defined as -0.5 cos(θ-1), where θ is the maximum cone angle collected by the objective according to its NA. A higher NA objective will collect a larger percentage of the light emitted from an isotropic fluorophore and therefore achieve higher signal-to-noise ratio and/or allow the user to reduce excitation power.

Focal length (F), Magnification (m) and Field of View

In infinity-corrected microscopes (Figure 1), magnification is a ratio of the focal length of the tube lens (FTL) to the focal length of the objective lens (FObj, eq. 3). For fluorescence applications, it’s important to consider the interaction between objective focal length, size of the optics and the spectral response of the filter. Additionally, the magnification (and therefore tube lens focal length) must be determined in consideration of sensor size and resolution, as well as packaging constraints. Our engineers can help you work through these inter-related requirements and determine the optimal custom objective lens and tube lens specifications.

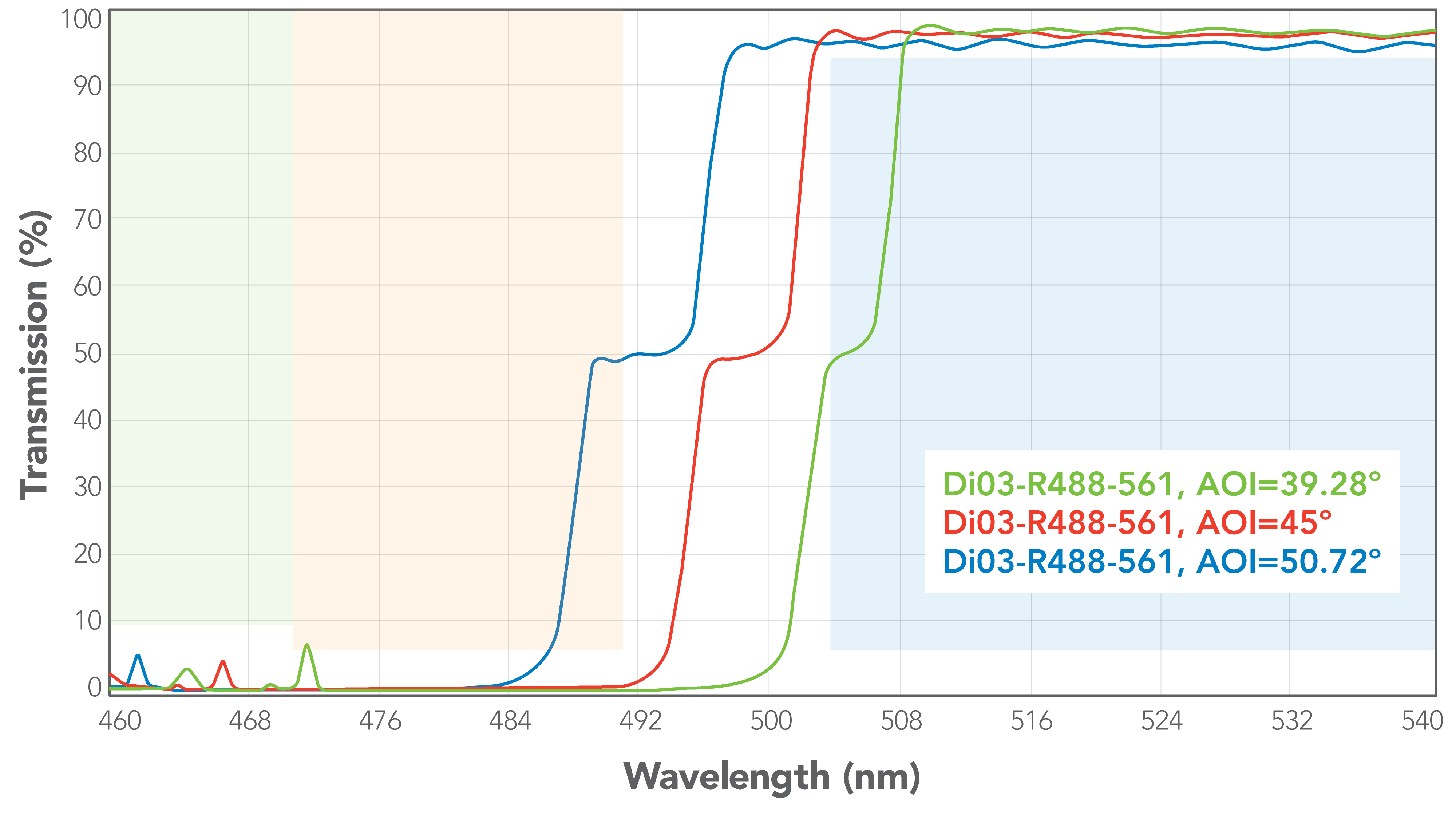

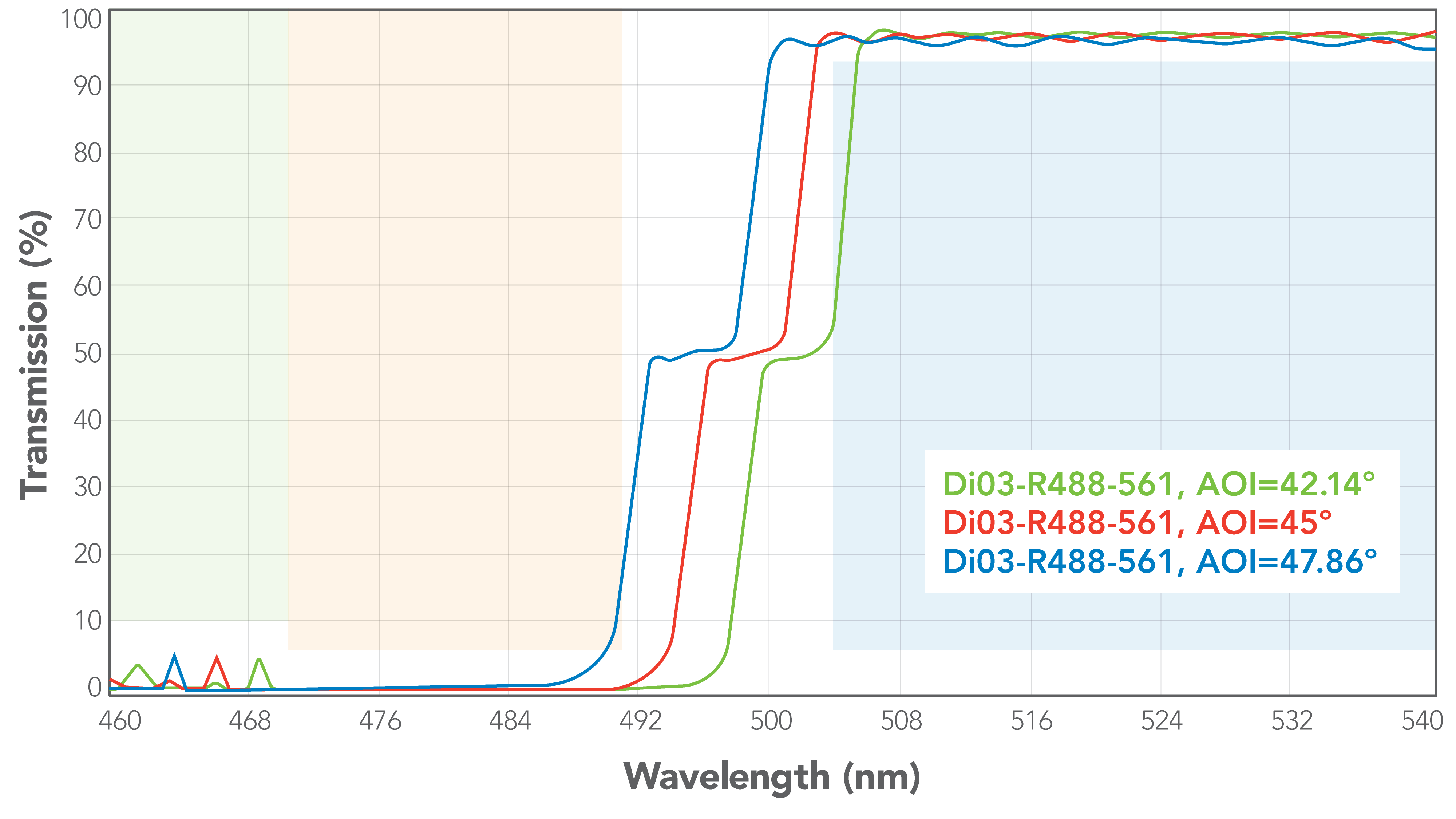

Field of View (FOV) describes the object area that will be transmitted to the detector. The FOV is typically a driving parameter of the optical design, and the sensor and magnification are chosen to ensure the FOV is captured by the camera. For an infinity-corrected objective, an angular FOV proportional to the objective focal length exists in collimated space (eq. 4). As shown in Figure 2, this angular range can shift the spectral response of the filters in this space and must be considered in the optical design.

Fluorescence detection requires effective blocking of excitation and stray light to maximize SNR. The fluorescence emission peak should fall within or near the transmission range of the emission filter (Figure 1). The blocking level should be high (OD > 5) over the excitation region and extend through the optical sensor response range, though the blocking can be reduced at long wavelengths where the sensor spectral efficiency is low.

Optical sensors have different properties including response time, amplification, dynamic range, spectral response, and dark noise level. However, the spectral efficiency of a sensor largely depends on the materials from which it is made. Semiconductor-based

sensors are often composed of doped Silicon for visible-range detection and Indium Gallium Arsenide (InGaAs) for NIR detection. These materials are used in single point sensors including photodiodes, APDs, SPADs, SiPMs as well as in area sensors such

as CCD and SCMOS cameras. An older type of detector is still widely used -- the photomultiplier tube (PMT), based on a vacuum tube structure. Typical spectral response curves of the primary sensor materials are shown in Figure 2.

|  |

Figure 2A) Example of dichroic mirror spectral shift vs angle. The maximum angle (±5.72°) produces a large shift in the spectral response of the dichroic mirror. Figure 2B) When the maximum angle on the dichroic mirror is reduced by half, the overall spectral shift is much smaller. For a fixed field of view, this can be achieved by doubling the objective focal length.

Working Distance

The working distance (WD; Figure 1) is a measure of how far away the object of interest is from the front surface of the objective lens. This surface can be metal or glass depending on the design of the objective lens. Some applications require long WD (several mm or more) to accommodate samples of various sizes, to focus through thick samples, or because of mechanical constraints near the sample. In high-throughput applications such as NGS (next-generation DNA sequencing) and slide scanners, a large WD is less important, especially in automated systems where samples are nearly identical in size and shape. A larger WD can drive objective lens size and complexity, particularly when the NA is high.

Other Important Specifications

Other important specifications for objective lenses include sample-specific requirements such as cover glass material and thickness, and immersion media, as well as mechanical constraints such as length, diameter and weight. These requirements must be specified at the onset of the design process, as they can dramatically influence the evolution of an objective lens design. TheXPLAN line of lenses was designed to work with a broad range of cover glass options via a one-time factory adjustment that customizes the objective to the desired cover glass thickness.

Aberrations

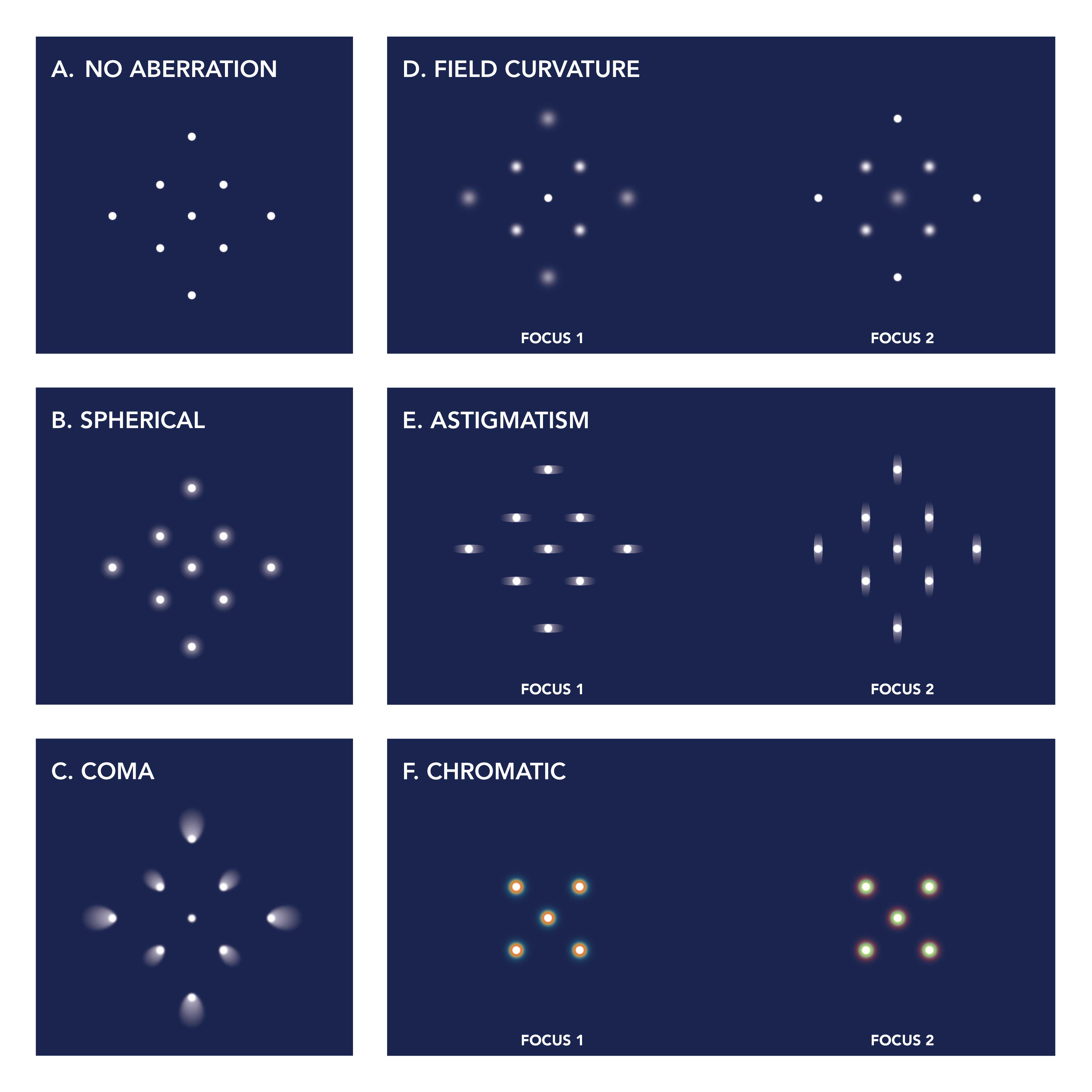

To achieve the resolution promised by eq 2., high-performance objective lenses must be designed to provide diffraction-limited imaging across the FOV. To maintain diffraction-limited imaging, the lenses must be fabricated with tight tolerances and mounted very accurately with respect to one another. Aberrations are artifacts in images that can arise from geometry, material properties and assembly errors. Many different aberrations can be present simultaneously to reduce the resolution of the optical system. Figure 3 illustrates the effect of different types of common aberrations on the image of a grid of points.

Figure 3. (a) field of dots with no aberrations, (b) spherical aberrations, (c) coma, (d) field curvature at two foci, (e) astigmatism at two foci, (f) chromatic aberration at two foci.

Figure 3. (a) field of dots with no aberrations, (b) spherical aberrations, (c) coma, (d) field curvature at two foci, (e) astigmatism at two foci, (f) chromatic aberration at two foci.

When spherical aberration (Figure 3b) is present in an objective lens, the focal length of the objective varies with pupil radius, causing the marginal ray to focus at a different position than a ray closer to the optical axis. Coma (Figure 3c) occurs when the magnification of the system varies with pupil position, causing a dot to flare out and look like a comet, or ice cream cone, when imaged through the system. Field curvature (Figure 3d) describes the phenomenon where the lens best focuses the image on a spherical surface rather than a plane. When using a flat sensor, a lens with field curvature will not be able to bring the full field of view to focus in one image.

Astigmatism causes the optical system to have a different focal length for rays in the horizontal and vertical meridians. This results in the optical system having two foci that are shaped as ellipses rather than points (Figure 3e). Astigmatism can arise from assembly errors such as tilt or decenter of elements, as well as stress caused by improper cementing of doublets and triplets. One of the many reasons our IDEX Health & Science team can deliver diffraction-limited imaging performance imaging performance is because we have optimized the optical assembly process to minimize astigmatism in our objective lens assemblies.

Distortion can occur even when all rays successfully reach the detector in perfect focus. The position of the points on the focal plane may be distorted in a pincushion or barrel shape. This is because distortion causes the magnification of the system to vary with image height. Although distortion does not impact whether or not a feature is resolvable, it can make it difficult to map features from the sample to the image or from one camera to a second camera. IDEX Health & Science routinely designs objective lenses with very low distortion that follows a simple polynomial fit, simplifying the process of distortion correction for our customers.

Chromatic aberrations occur because the refractive indices of glasses are wavelength-dependent. This causes wavelength-dependent focus shift and blurs the image. (Figure 3f) This shift can be corrected by using lenses made of different materials in the objective lens assembly. Our Melles Griot XPLAN™ CCG line CCG line of objective lenses achieve broad chromatic correction in the visible spectrum, while a custom design can stretch that chromatic correction into the ultraviolet or near-infrared spectra as needed.

The IDEX Health & Science Advantage

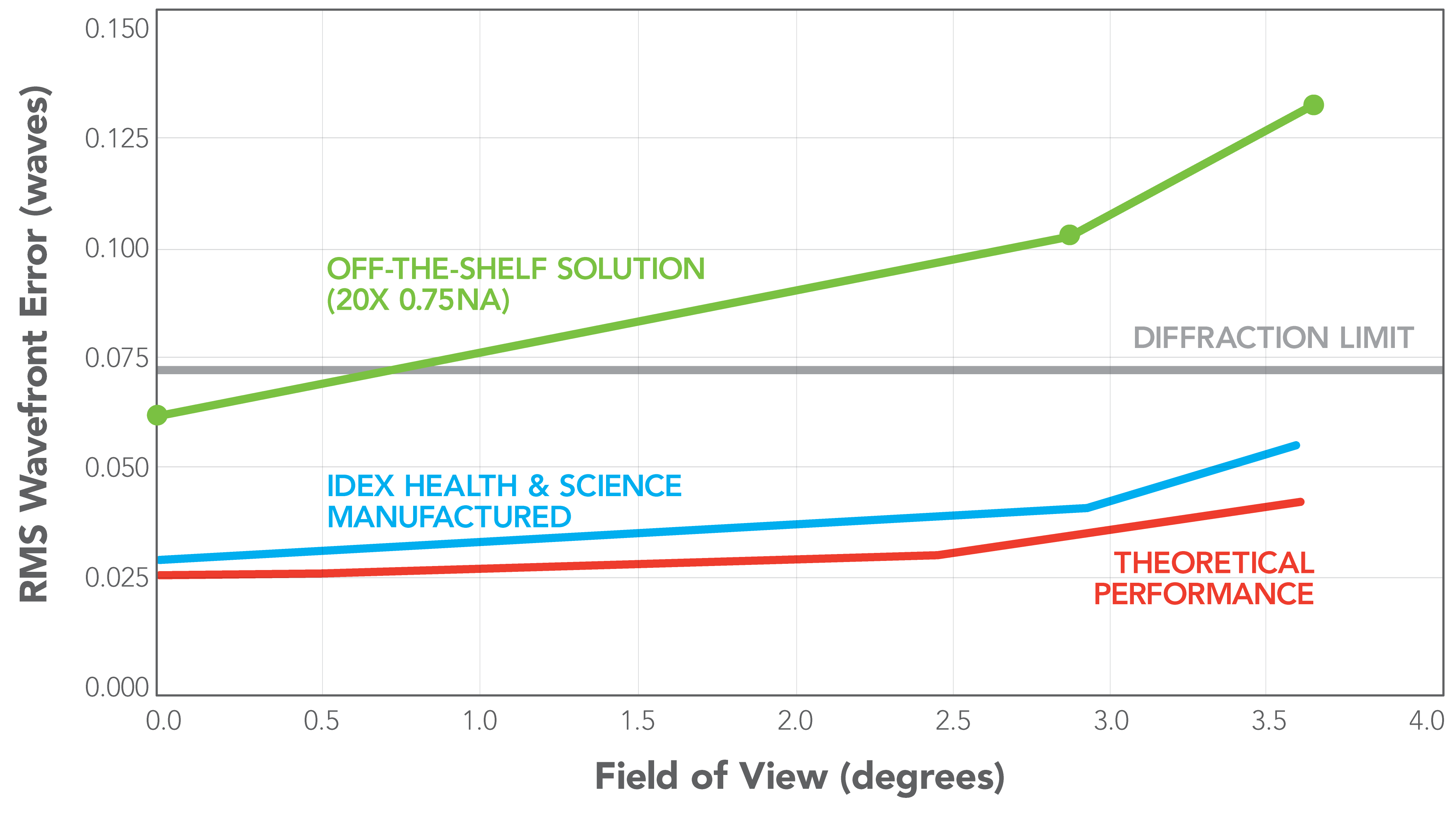

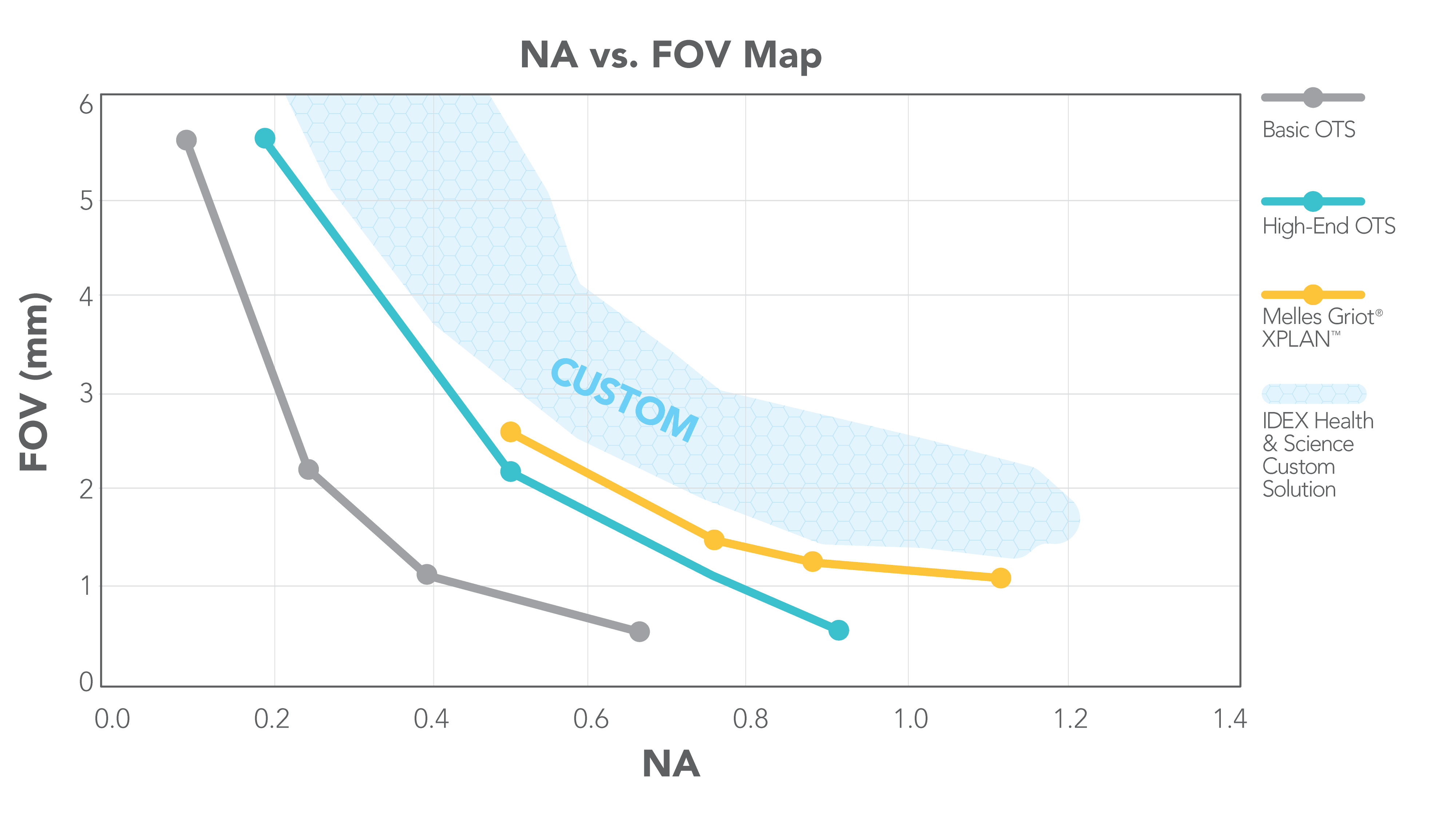

Traditional microscopy has used the human eye as the detector. As such, microscope objectives were designed to have high resolution over the very small central FOV of the human eye. Modern applications of microscopy include high-throughput imaging systems such as slide scanners and next-generation sequencing, which require both a large FOV and high resolution to achieve the desired imaging speed. As shown in Figure 4 below, our exceptional design and manufacturing capabilities ensure high resolution over a much wider FOV than typical off-the-shelf components. We completely characterize the wavefront error of each objective lens and provide documentation for every part. We can provide additional test data as needed – just ask!

Figure 4. (a - above) As-built wavefront error (blue line) of IDEX Health & Science objectives remains below the diffraction limit over the entire FOV.

(b - below) IDEX Health & Science specializes in high NA, large FOV objectives.

Choosing the right objective lens is paramount for achieving optimal performance in your microscopy application, balancing critical specifications like numerical aperture, focal length, working distance, and aberration correction. Our experienced optical engineers at IDEX Health & Science are adept at navigating these complex interdependencies to deliver custom solutions tailored to your unique requirements. We encourage you to leverage our expertise and comprehensive manufacturing capabilities to design and produce high-performance objective lenses for your specific needs.

Contact IDEX Health & Science directly to discuss your custom project here.