What Affects the Accuracy of an Instrument’s Test Results?

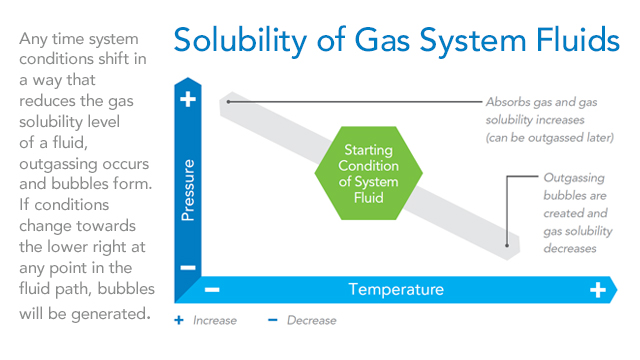

In the life science industry, repeatable test results from an instrument illustrate accuracy and a high-quality system. Challenges can arise when visible bubbles are generated in the flow path of the system. It can lead to a deviation in the test results, which is not directly related to the standard operation or maintenance of the instrument. However, it is directly related to objective factors, such as an increase in temperature, pressure drop, or change in reagent concentration. If targeted measures are not taken, the performance of the instrument will be affected, which is difficult to avoid.

Where do bubbles come from?

When the temperature, pressure, or chemical properties of the reagent in a system change, bubbles will form in the flow path. This is because the ability to dissolve gas has changed due to the change of conditions.

What types of instruments require degassing?

- IVD Instruments such as:

- Automatic biochemical analyzers

- Automatic immune analyzers

- Automatic serum analyzers

- Automatic hemagglutination analyzers

- Automatic urine analyzer

When a system is optimized, accurate sampling and reagent filling, aids the accuracy of test results. This allows the dispensing system of clinical testing instruments to have excellent performance.

- Flow Cytometry

- DNA Sequencer

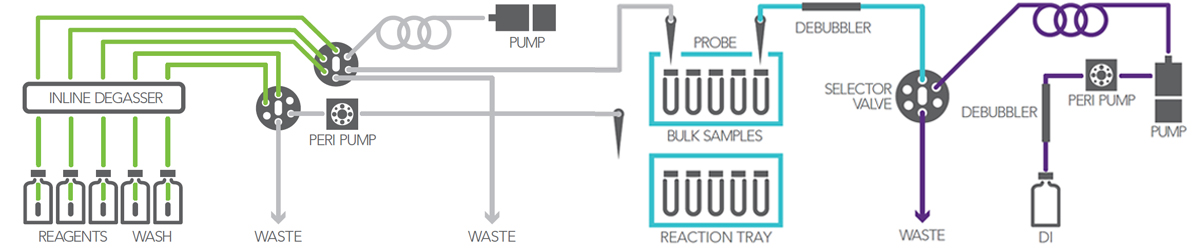

It’s beneficial to have a piston pump with long service life and high precision, but it is also beneficial to include a degasser before the pump in the flow path. This helps to avoid bubbles due to a sudden decrease of pressure in the process of suction and spitting.

Generally, the pressure will change during system operation. The decrease of pressure in the flow cell in flow cytometry will reduce the dissolution rate of gas in the liquid and produce bubbles. These bubbles directly affect information obtained by the detection unit, and lead to the deviation of the final test results.

Therefore, it is necessary to install a degasser before the flow cell to remove dissolved gases before they outgas into bubbles.

In DNA sequencers, especially sequencers that use a scientific camera, the flow cell is the most sensitive area to bubbles. Bubbles typically aspirate from the flow cell. The main reason this happens is because the liquid temperature increases, the pressure decreases, and the concentration changes due to the mixing of different reagents. Each single factor will reduce the air dissolution rate in the liquid, and the superposition of the three factors increases the possibility of outgassing.

Therefore, it is necessary to install a degasser before the flow cell to remove dissolved gases before they outgas into bubbles and to ensure the accuracy of the test results.

How do you select an outgassing reagent and the position of the degasser?

- It is not recommended that the degasser is placed in the public channel in front of the flow cell, which will increase the consumption of expensive reagents.

- It is recommended to select approximately three different reagents for degassing and place them between the reagent probe and the multi-position switching valve.

Other Common Fluctuations in a Flow Path

- Cleaning reagent with a large flow. A large flow will accumulate relatively more aspirated gases, and once they gather, they will form visible bubbles.

- Reagent flowing into the flow cell during imagery. When the camera is taking the image, the photo quality is directly affected by the bubbles from the reagent.

- Reagents can cause fluctuations in the concentration of chemical components. Degassing the reagents can reduce the amount of aspirated bubbles caused by the change of concentration.

What is the Importance of Degassing?

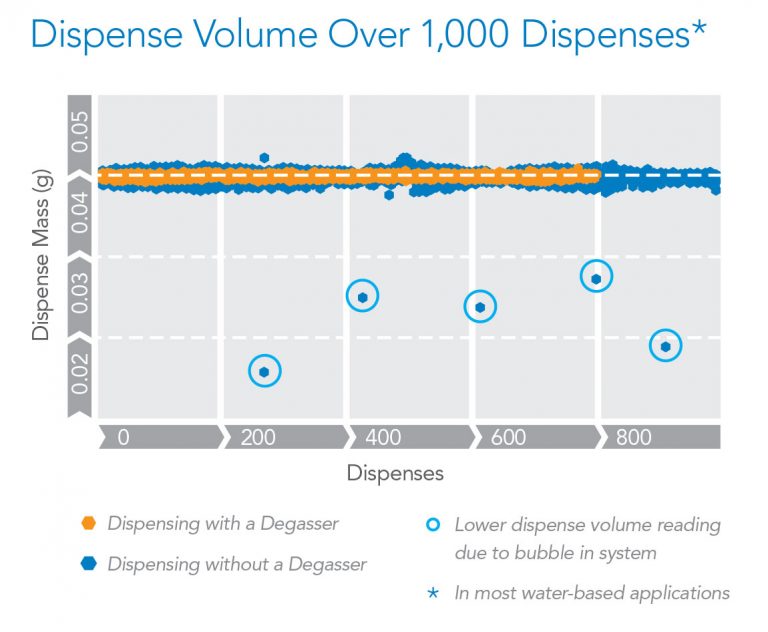

Degassers greatly improve precision by degassing fluids far below the saturation point so instrument operations remain bubble-free. Without degassing, repeat sampling is required to detect inaccurate readings, which reduces throughput along your fluidic path. If bubble formation is not initially identified, sample assessment may be flawed. As the graph below demonstrates, degassers greatly increase accuracy for dispense volumes over time, in standard operation.

Learn how to produce consistent and accurate sample results by incorporating a degasser in your instrument in this Stories & Features blog.

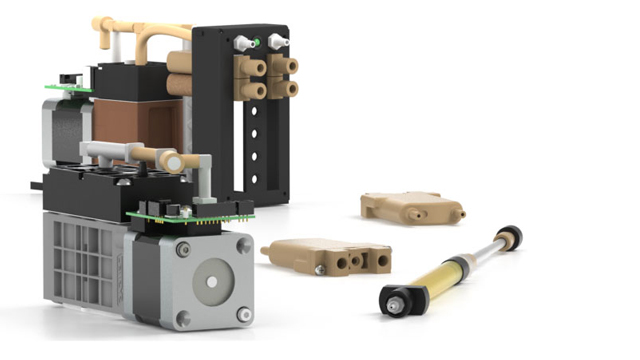

IDEX Health & Science Degassing Product

We offer a broad portfolio of vacuum degassing assemblies to control bubbles in a wide range of system-fluids and flow-rates. Key benefits include:

- Stable degassing efficiency

- Customizable design

- Reliable vacuum control system

- Compact flow path

- Long service life

- 20+ years of practical achievements in the IVD market