Advice to Effectively Use Fittings and Tubing in Fluidic Systems

Fittings Basics

Fittings are typically comprised of a nut and a ferrule and have the important function of providing the physical connection of tubing throughout most systems. While simple in function, fittings exhibit some complexity regarding their description and how they are used.

Using Stainless Steel Fittings

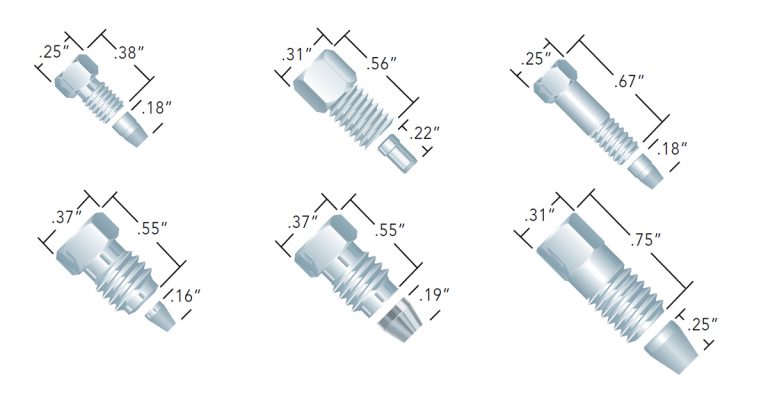

Although restrictive in use and non-universal in application, stainless steel fittings are the most popular fitting used on HPLC systems today, due to their solvent inertness and high-pressure holding abilities. These fittings usually come in a conical configuration, requiring special care to be taken in choosing the proper fittings for any given mating port. To ensure proper operation and long life from the chosen fitting, it is best to use fittings specifically designed for use with a particular manufacturer’s port. Pictures of different nut and ferrule geometries are presented in the picture below.

Using Polymer-Based Fittings

Unlike their stainless steel counterparts, polymer-based fittings are typically nonrestrictive and fairly universal in function. Because of the nature of polymer-based fittings, the same degree of care does not have to be taken when choosing the proper fitting to mate with a specific manufacturer’s receiving port. Primarily, the only two characteristics of the fitting that must be known are the geometry (coned or flat bottom) of the receiving port and the thread dimensions. Polymer-based fittings also do not permanently attach (swage) to a piece of tubing and usually do not require the use of any tool (besides your fingers!) to properly tighten and use. These fittings often come in a variety of polymers, including PEEK, PTFE, Tefzel, Delrin, PPS, polypropylene, and others, for maximum cost and solvent resistance flexibility.

Swaging Instructions

In order to properly use stainless steel fittings, the ferrule portion of the fitting must be swaged — or permanently attached — to the tubing it is connecting. To appropriately swage the fitting to the tubing, we recommend the following procedure:

- Place the nut and ferrule, in that order, on the tubing.

- Place the loosely assembled fitting into a mating port, and tighten the nut finger tight.

- While ensuring the tubing is bottomed out inside the mating port, tighten the nut with a wrench an additional 3/4 of a turn.

- The ferrule should now be permanently attached to the tubing.

Because the ferrule is permanently attached to the tubing, and because of standard machining tolerances, we highly recommend that any pre-swaged stainless steel fitting only be used in the mating port into which it was initially swaged. Failure to do this may result in dead volume or solvent leakage.

Keep the Following in Mind When Using Fittings and Tubing in Your Fluidic Design:

- Be wary of re-using your permanently swaged fitting types on other ports. The length of tube exposed after the ferrule (and the geometrical details of the ferrule) can vary on different ports. This means that void volumes, leaks, or port damage could occur if incorrect pre-swaged ferrules are swapped between different fittings.

- Don’t use stainless steel ferrules in polymeric ports. These ferrules will damage the receiver ports. You can use any type of ferrule in a stainless steel port.

- It is always a good idea to look down inside a port before tightening a new fitting in. Look for old ferrules that have been left behind or other debris. This simple practice can save you a lot of grief in the long run. If you notice a fitting feels different than usual as you tighten (e.g., softer or grittier), stop tightening and look inside the port.

- Be careful when routing tubing on your instrument. We often find that careless routing can affect flow precision and accuracy, particularly if tubing is attached to moving, vibrating, or heating objects. Just because your sample transfer tube fits through that little space between the vibration head and the plasma arc in the solid model, doesn’t mean it should really go there…

- The internal volume of a tube scales with the square of the tube radius, and the amount of care required in keeping it unplugged and running optimally scales with the inverse square of the diameter. Use clean fluids and short runs of very small ID tubing for maximum reliability.

We have an excellent resource on making connections properly. Our Fittings 101 Guide includes descriptions of all the different liquid connection types that you are likely to encounter to enhance your fluidic system design.