Stories & Features

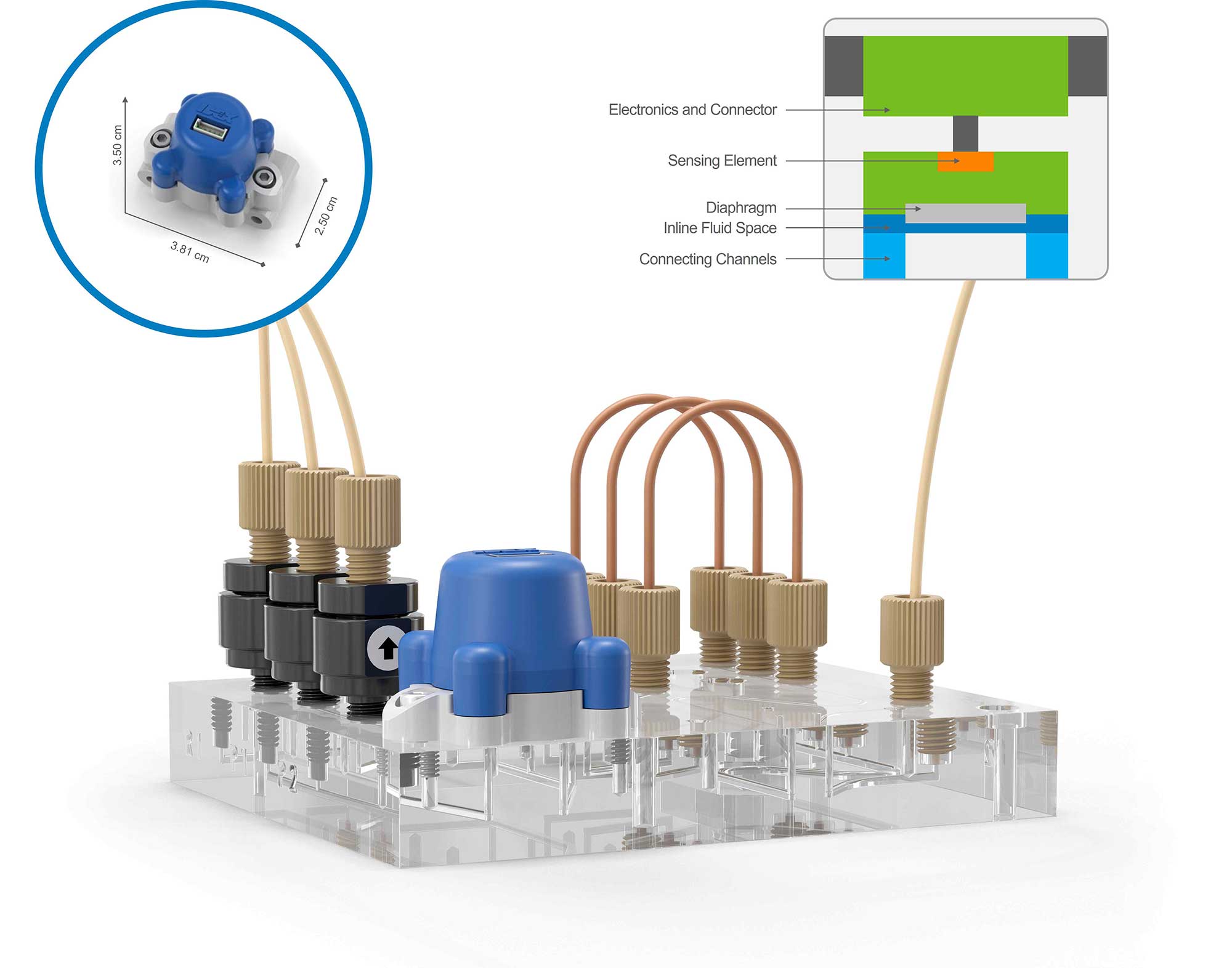

Immediately detect blockages and mitigate risk before important samples are compromised with modular pressure sensors from IDEX Health & Science. The PS200 pressure sensor allows you to continually monitor system pressures for reliable instrument operation up to 200 psi (13bar). The fully isolated MEMS sensing element reacts instantly to pressure changes in your fluidic pathway, offering precise pressure monitoring and tight control over your fluidic operations.

Our fully swept pressure sensors, provide real-time insights into pressure changes—ideal for both application optimization and instrument diagnostics. Low internal volume and a fully swept inline fluid pathway ensure that the sensor will not disrupt your analytical performance.

A fully isolated MEMS sensing element reacts instantly to physical pressure changes of the fluid transmitted through a gel-filled cavity. Signal conditioning, analog-to-digital conversion, and I2C are provided by onboard electronics.

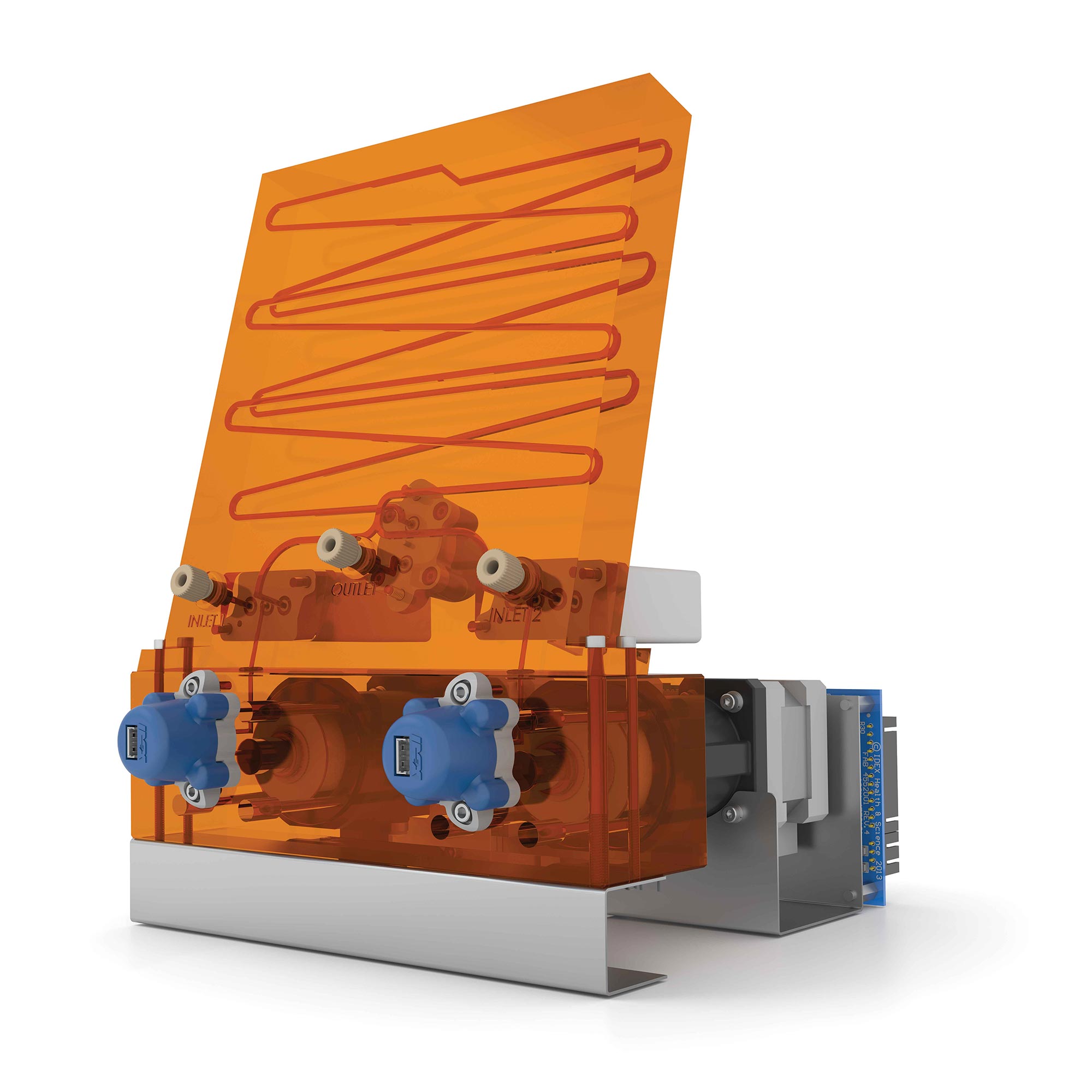

Our pressure sensors can be used as a stand-alone implementation or mounted with a manifold for seamless system integration.

Stand-Alone Sensors

Manifold Mounted

QuickStart sensor kits allow you to quickly get measuring with integrated USB adapter and Quick Start software for real-time monitoring. For quick system testing, our IDEX Health & Science Library—Powered by Python™ programming language offer a powerful yet easy-to-use syntax, for quick programming of sensors.

Let the good times flow with real-time pressure measurements.

Surface Plasma Resonance (SPR), life science applications, bioprocessing, and benchtop measurements.

Access our pressure sensor data sheet.

Quick Start Sensors Tutorial

IDEX Health & Science Library