PEEK Tubing for Life Science Applications

Key Benefits of PEEK Tubing

- 1/16” or 1/8” outside diameter available

- Biocompatible, inert, and easily cut

- Great for high-pressure applications

- Maximum continuous use temperature: 100 ºC

Our PEEK (polyetheretherketone) polymer tubing is biocompatible, chemically inert tomost solvents, and can be used to replace stainless steel tubing in most liquid analytical systems. Unlike stainless steel tubing, PEEK tubing is flexible and can be easily

cut to desired lengths.

PEEK tubing has a very smooth internal surface, which causes less turbulence than similarly sized metal tubing, contributing to improved resolution of sample bands. Of all our polymer tubing materials, PEEK is the least permeable to gas.

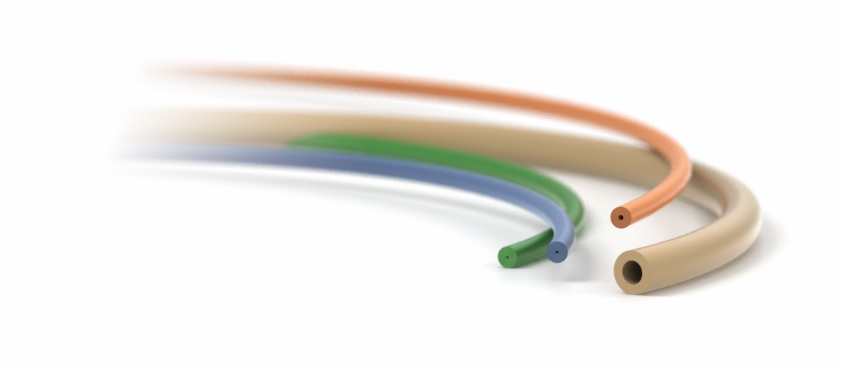

In addition, much of our 1/16” OD tubing is color-coded so different IDs are easily identified. Our proprietary extrusion process ensures color permanence in our tubing. Our 5’ length tubing is rough cut to approximately 5’1”. A trim cut should be made before use, especially for smaller ID tubing. PEEK tubing can be cut easily with a razor blade. However, for an improved cut, try our Tubing Cutters.

Capillary PEEK Tubing

- 360 μm or 1/32” outside diameter available

- IDs as small as 25 μm (0.001”)

Capillary PEEK tubing offers all the benefits of larger sized PEEK tubing, while serving as an excellent alternative to more traditional fused silica and stainless steel capillary tubing (see Application Note below). The capillary tubing can be coupled to many of the products in our Connectors product line and to some of our valves.

Fused Silica Tubing

- Five inner diameters with most common capillary outside diameter, 360 μm

- Cut in convenient lengths, up to 2 m

These products are manufactured from synthetic fused silica with a polyimide coating.

Tech Note:

Because the through-hole of our 25 μm ID PEEK tubing is very small, it is possible for some fittings to cause the ID to become occluded. Please use caution, especially with wrench-tightened fittings

Application Notes and Tips:

What Size PEEK Tubing Should I Use?

- It is usually safe to use 1/16” OD x 0.010” ID tubing throughout an analytical HPLC system. With a 0.010” ID, the pressure drop across most tubing lengths is negligible, and the ID is small enough to minimize band broadening.

- High-pressure semi-prep LC systems will most likely use 1/8” OD tubing.

- Use our 1/32” OD tubing for the high-pressure flow path of some microbore HPLC systems.

- Choose 360 μm OD tubing for most capillary systems.

- PEEK tubing is also available by the inch.

Peek Tubing in LC-MS Applications

An independent study conducted by a major pharmaceutical company indicated LC-MS chromatographic performance could be improved in some cases by switching the post column transfer line from fused silica to PEEK polymer tubing. The switch dramatically reduced peak tailing and eliminated the degradation of peak symmetry as injection volume was reduced.

How to Straighten Peek Tubing

To straighten PEEK polymer tubing, first choose a piece of stainless steel tubing with an inner diameter slightly larger than the OD of your tubing and with an appropriate length for the PEEK tubing you wish to straighten. For instance, for 1/16”

OD PEEK tubing with a length of 10”, choose our U-825 tubing (stainless steel, 1/8” OD x 0.080” ID x 25 cm long, page 19. Slip your PEEK tubing into the stainless steel tubing. Place this “sleeved” tubing into an oven

and bake at 425 ºF (218 ºC) for 30 minutes or 350 ºF (177 ºC) for 60 minutes. Allow the sleeved tubing to return to room temperature naturally (i.e., do not quench it with water). Once cooled, remove the PEEK tubing from the stainless

steel sleeve and inspect it for straightness. If needed, repeat the process until the desired straightness is achieved.

| Tubing OD | Tubing ID | OD Tolerance | ID Tolerance |

|---|---|---|---|

| PEEK TUBING SPECIFICATIONS | |||

| 1/16” | 25 μm | ±0.001” (25 µm) | ±0.0005” (12.5 µm) |

| 1/8” | All | ±0.003” (75 µm) | ±0.003” (75 µm) |

| CAPILLARY PEEK TUBING SPECIFICATIONS | |||

| 360 µm | All | ±0.0005” (12.5 µm) | ±0.0005” (12.5 µm) |

| 1/32” | All | ±0.0005” (12.5 µm) | ±0.0005” (12.5 µm) |

| FUSED SILICA TUBING, 360 µm OD | |||

| 360 µm | 20 µm (0.0008”) | ±0.0004” (10 µm) | ±0.00008” (2 µm) |

| 360 µm | 50 µm (0.002”) and 75 µm (0.003”) | ±0.0004” (10 µm) | ±0.00012” (3 µm) |

| 360 µm | 100 µm (0.004”) and 150 µm (0.006”) | ±0.0004” (10 µm) | ±0.00016” (4 µm) |