Microfluidic Chip Reagent Storage that is Ready for Integration

The Problem: Integration is a Barrier

Integrating blister technology into existing microfluidic cartridges previously meant one thing: a complete redesign. For many potential customers, this was a costly and time-consuming hurdle that delayed testing and slowed down development.

Our Solution: From Roadblock to Ready

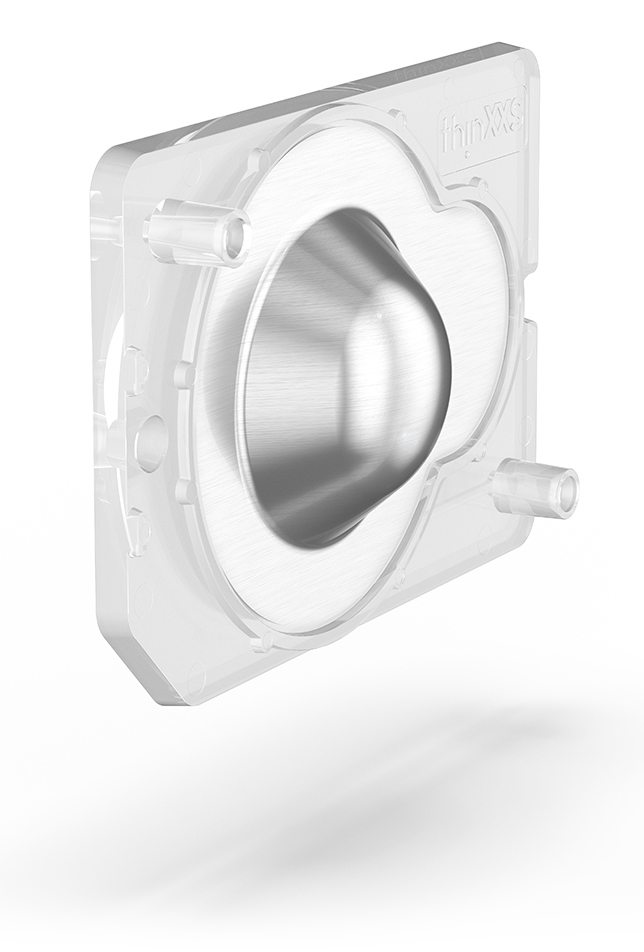

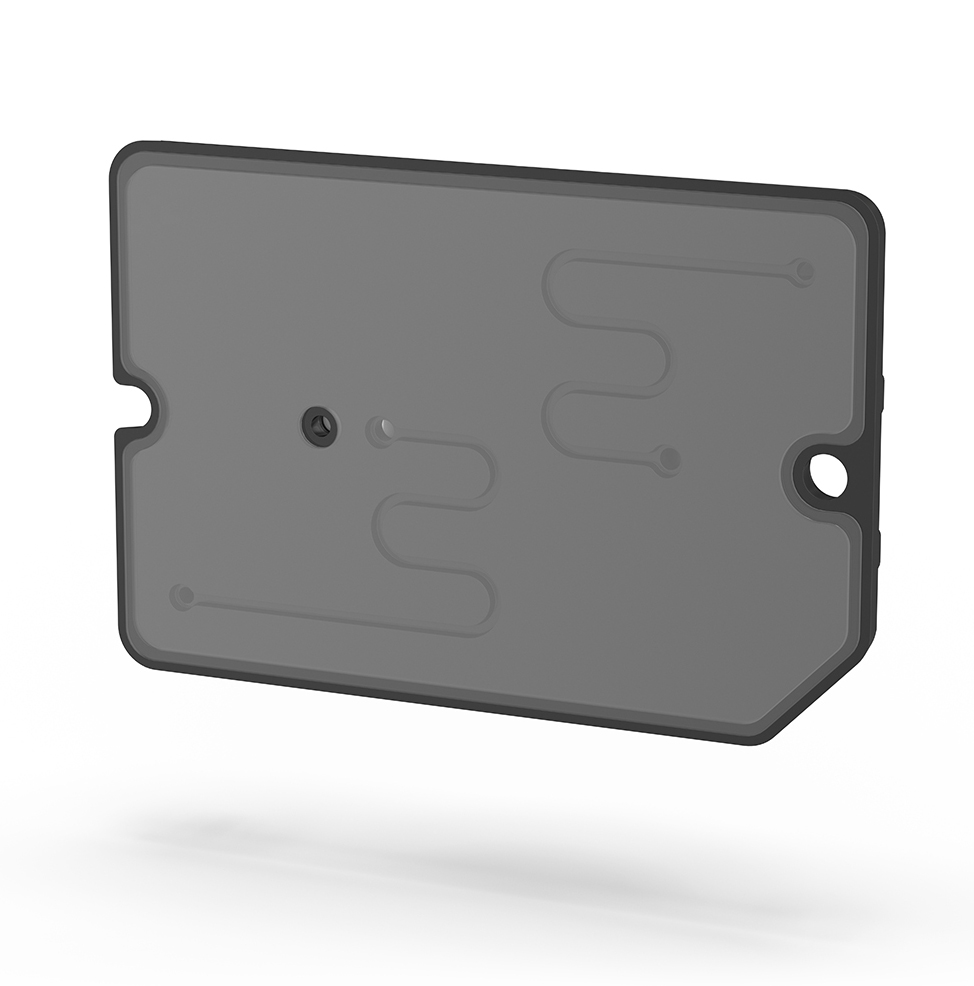

Now you can easily integrate this new blister technology into your existing reagent cartridge. This new chip is a standalone blister that can be easily attached to an existing cartridge—no need to redesign your microfluidic chip to integrate

our blister technology. You can begin shelf life and material compatibility testing right away without having to wait for a custom cartridge design.

How it Works: Greener and Leaner Manufacturing

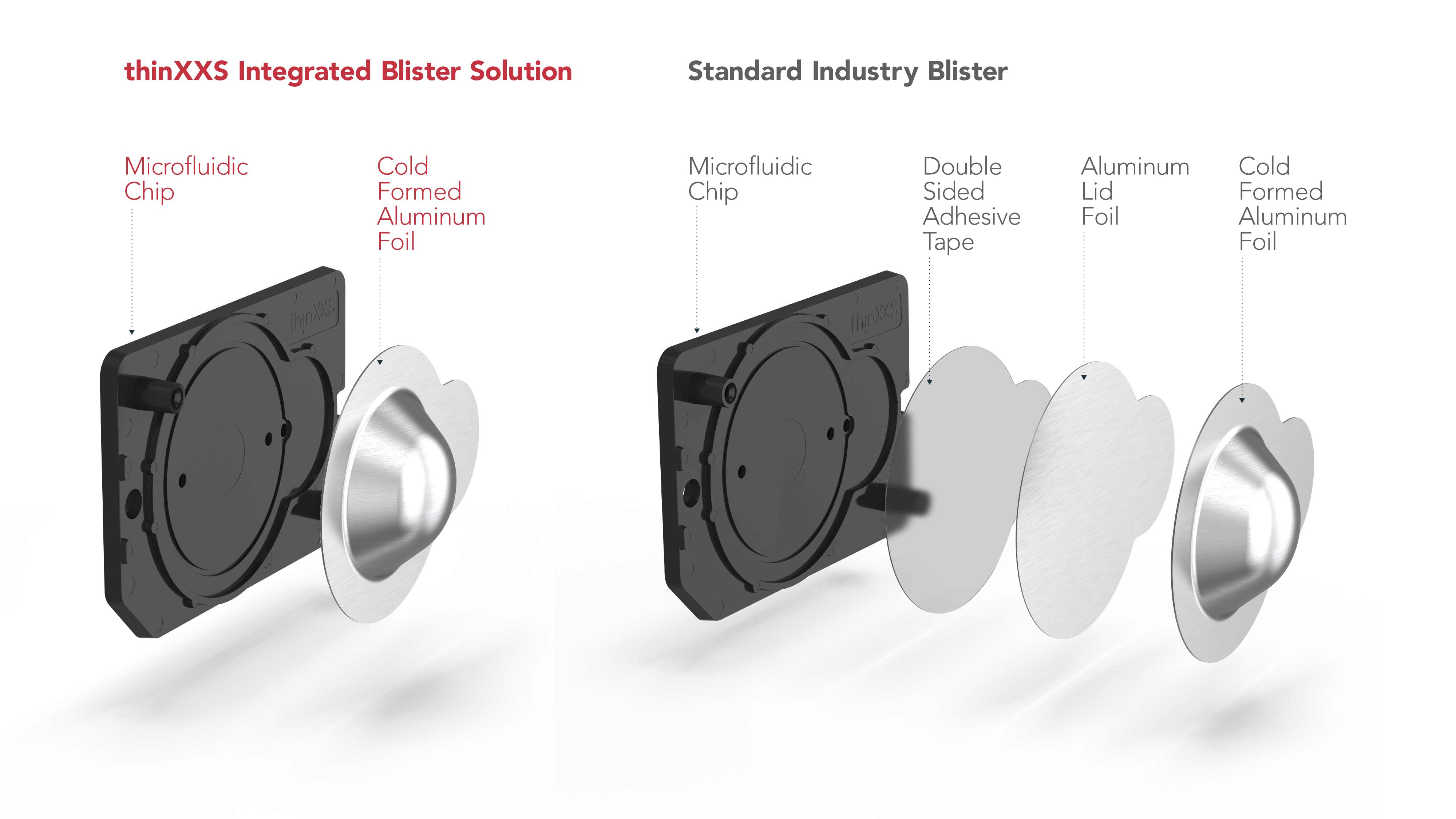

The new thinXXS blister pack technology uses significantly less materials and requires fewer process steps. This technology offers a compelling alternative for already established microfluidic cartridges with integrated wet reagent storage.

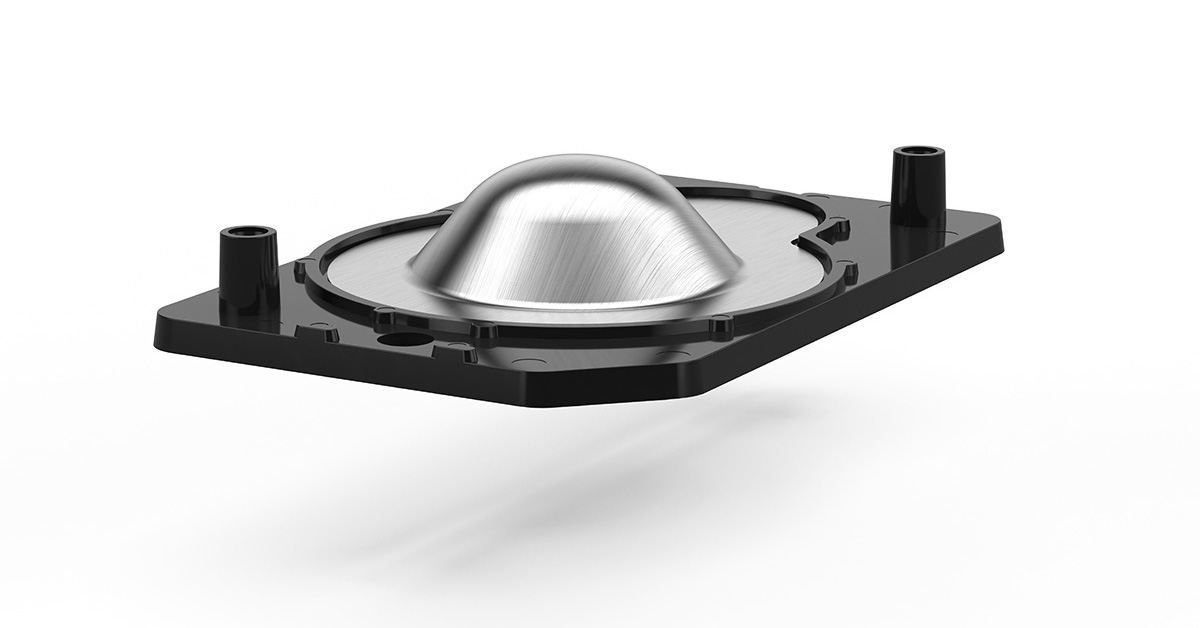

The blister pack utilizes a cold-formed aluminum foil that is directly sealed onto the microfluidic chip, offering liquid reagent storage devices that can be easily attached to 3D printed parts or rapid prototyping cards. The reagents can be filled afterwards into the chip, either by the customer or by thinXXS.

A simplified overview of the new blister pack technology from thinXXS

By bringing us into your initial design conversations, we can help streamline your bill of materials, resulting in cost and efficiency benefits—if the cartridge is specifically designed to integrate the blister solution. This lowers costs and reduces manufacturing tolerances.

Features and Benefits of the Microfluidic Blister Packs for Reagent Storage

FEATURE | BENEFIT |

Scalable technology | Proven technology for low-volume as well as high-volume manufacturing. |

| Air-free filled blister packs | No unwanted introduction of air into microfluidic system—no impact on reagent stability. |

No delamination possible | No risk of contamination within the instrument, making results more reliable. |

Applications

Bioprocessing

Cell Gene Therapy

Cell Isolation

Flow Cytometry

IVD Bio

Lab Diagnostics

Molecular Assay

Point of Care

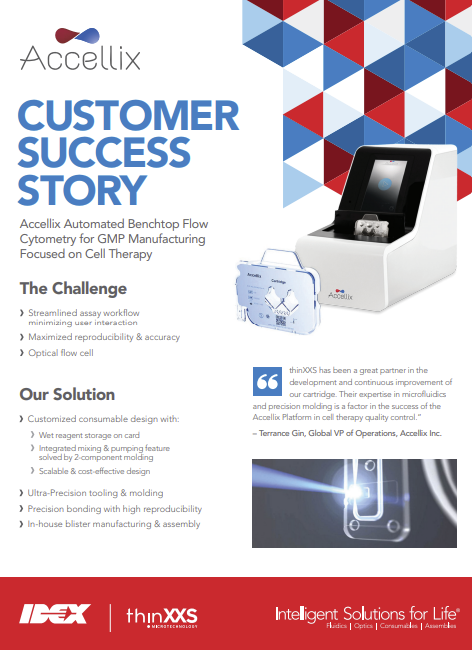

Customer Case Study: Accelllix

To see this innovation in action, check out how one of our customers is leveraging this technology to meet the rigorous demands of flow cytometry. This success story underscores the compatibility of the blister pack with high-quality, precision-driven applications.

Trust thinXXS for your blister technology to deliver performance while significantly reducing the bill of materials and offering a scalable path forward to your microfluidic wet reagent chip storage solutions.