Manifolds - The Heart of Fluid Management

Enhance Instrument Consistency and Eliminate the Mess with an Integrated Manifold Subsystem

Instrument design often begins as a simple sketch on a whiteboard, with tubing and fittings used for early prototyping. Upgrading your design to a manifold provides an elegant, reliable solution for fluid management.

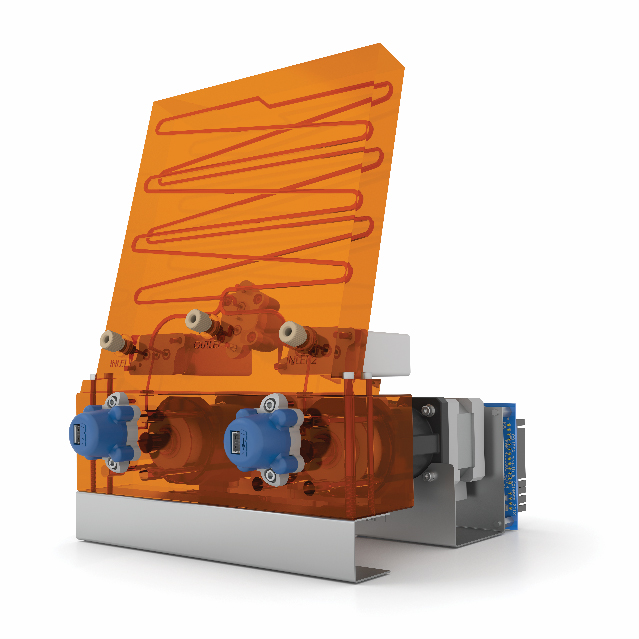

Your customized manifold becomes the heart of fluid management, from which components are incorporated to direct flow, sense pressure, and degas lines. Integrating these components into a unified architecture reduces plumbing complexity, minimizes the risk of leak points, and saves time for installation and servicing.

From Mess to Manifolds

Figure 1: Clusters of tubing and fittings can over-complicate the fluidic pathway making installation and troubleshooting incredibly cumbersome.

Figure 2: Streamline your fluidic path and guarantee consistency with a custom manifold from IDEX Health & Science.

Many polymers are available for machined manifolds — multilayer manifolds primarily use PMMA (acrylic) for a fully transparent manifold or PEI (Ultem) for applications utilizing more aggressive reagents.

With over 60 years of experience making custom manifolds, we’ve perfected machining and processing.

IDEX Health & Science Manifold Capabilities:

- 0.020” channel diameter

- 0.005” tolerancing

- Square, round, and “D”* channels 16 µin channel surface roughness

- <20 µin external surface finish

- 60+ years of DFM experience

Additional Benefits:

- Reduced number of leak points and complexity

- Simplified installation

- Consistent fluidic performance in every instrument, every time

- Enhanced system reliability