Manifolds- 3D Prototype to Deliverable

How do you handle customized fluidic design iterations when you are on a tight timeline and budget?

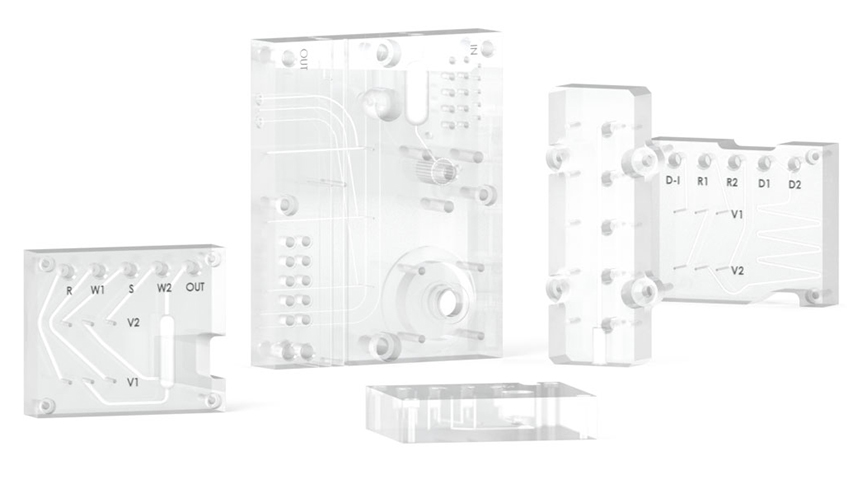

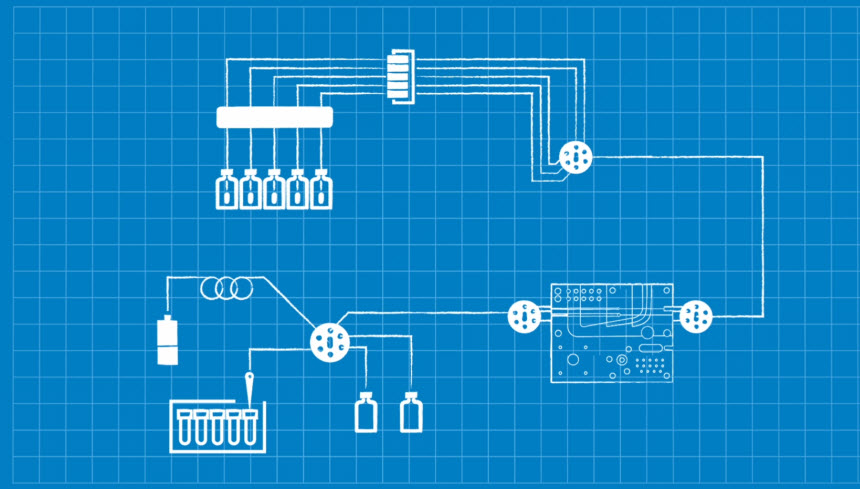

In fluidic pathway development, the most efficient way to optimize your system is to integrate a manifold to reduce device size, decrease leaks, and add valves and pumps. This will improve reliability of the flow path and provide consistent performance.

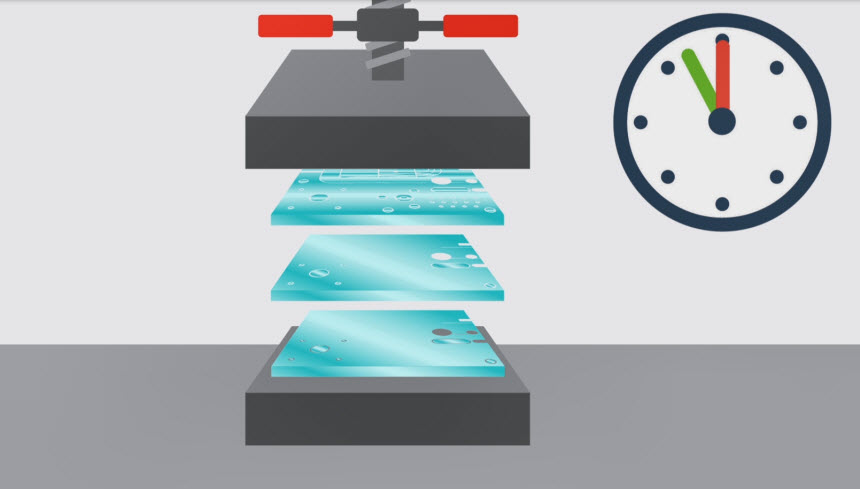

In the past, engineers designing complex fluidic channels in manifolds would need to wait patiently for a manufacturer to produce prototypes. Made through process-intensive lamination methods, each layer would be individually machined to add fluid tracks before they were carefully aligned and stacked. Through a combination of heat and pressure, the assembly would be diffusion-bonded to join the layers together. Subsequent machining is required to finish the manifold, polish, and ship. This method is costly and takes weeks to deliver. Any design iterations added more time and more cost. A manifold can provide useful flow data and eliminate unknowns, but long lead times can hurt project timelines.

To update assembly iterations on a tight timeline, we have developed a program called, “Manifold-in-a-Week”.

We can develop a 3D printed manifold prototype to review the basis of your overall design requirements. In this critical step, not only is a fully-functional manifold produced, conventional manufacturing methods are established for later production. This step can save you time and money without cutting corners on quality. During manufacturing, we use additional machining operations to give each manifold glass-like clarity so you can visually monitor fluid movement during the development phase.

In a competitive landscape, “Manifold-in-a-Week” allows you to optimize the form, fit, function, and manufacturability of your fluidic path with high quality, cost-effective prototypes — from order to delivery in just seven days. Learn more about this manifold program in this video or on our website.