Achieve Leak Free and Safe Connections with Tubing Sleeves

Most capillary tubing connections are made into coned receiving ports—ports that aren’t actually designed for direct use with capillary tubing. Creating a reliable, leak-free connection takes extra care. Custom ferrules can help, but their fixed-length noses don’t always match the slightly varying depths of tubing pockets, which can result in leaks or unwanted dead volume.

To keep costs down while still achieving a low–dead-volume connection, we recommend using tubing sleeves. Unlike fixed ferrules, sleeves aren’t permanently attached, allowing them to accommodate different pocket depths. And, because they’re made from extruded polymer tubing, you get consistent concentricity built right into the connection.

What are the benefits of using tubing sleeves in Life Science and Medical Device Applications?

- Protection and Insulation

- Secure Connections

- Safety and Hygiene

MicroTight® Tubing Sleeves

- Manufactured from PEEK polymer

- Pressure rated to 4,000 psi (276 bar)

- Color-coded for easy inner diameter identification

IDEX Health & Science MicroTight Tubing Sleeves feature an outer diameter of 0.025” and offer a wide assortment of inner diameters to help facilitate capillary tubing connections with our MicroTight accessories. Because the sleeves are manufactured from PEEK polymer, they carry an upper temperature threshold of 125 ºC.

To use these sleeves properly, choose a sleeve with an inner diameter 0.001”–0.002” (25–50 µm) larger than the outer diameter of your capillary tubing. Then, slip the sleeve over your flow path tubing, such that your tubing extends all the way through the sleeve, but not beyond the end of the sleeve. Choose the correct fitting that corresponds with your receiving port, slide it over the sleeved flow path tubing, and connect as normal.

SHOP MICROTIGHT® TUBING SLEEVES

NanoTight™ Tubing Sleeves

- Manufactured from FEP fluoropolymer

- Pressure rated to 4,000 psi (276 bar)

- Outer diameter of 1/16” — the most popular size used on most instrumentation

IDEX Health & Science NanoTight Tubing Sleeves are manufactured using FEP fluoropolymer and precisely cut to a 1.6” length. A wide assortment of sleeves is available. Many of the sleeves feature a light color tint that can help more easily identify the inner diameter for future orders. Because FEP is the base polymer for these sleeves, there is a maximum recommended continuous operating temperature of 50 ºC.

Our NanoTight sleeves were designed primarily for use with the NanoTight™ fittings, and also work well with the Super Flangeless™ fittings for 1/16” OD tubing. For tubing sleeves that can be used effectively with stainless steel fittings and at higher temperatures, consider using PEEK Tubing Sleeves.

SHOP NANOTIGHT™ TUBING SLEEVES

1/16” OD PEEK Tubing Sleeves

- For connecting capillary tubing to standard 10-32 ports

- Require the use of wrench-tightened stainless steel nuts

- Pressure rated to 6,000 psi (414 bar)

Like the NanoTight™ FEP Sleeves on the previous page, these PEEK Tubing Sleeves are designed to be used with 1/16” OD, 10-32 threaded fittings to adapt capillary tubing to standard coned ports. Made of PEEK polymer, these 1.3” long sleeves can be used up to 125 °C.

These sleeves require a wrench-tightened nut to achieve proper sealing. We recommend our SealTight™ fittings. Many researchers also use a stainless steel nut and ferrule with these sleeves, such as our U-400 and U-401.

SHOP 1/16” OD PEEK TUBING SLEEVES

1/32” OD PEEK Tubing Sleeves

These 1.6” long 1/32” OD PEEK Tubing Sleeves can be used with any fitting designed for 1/32” OD tubing when smaller tubing must be connected. The 1/32” OD PEEKTubing Sleeves have a maximum recommended temperature of 125 °C and have a pressure rating of 5,000 psi (345 bar).

SHOP 1/32” OD PEEK TUBING SLEEVES

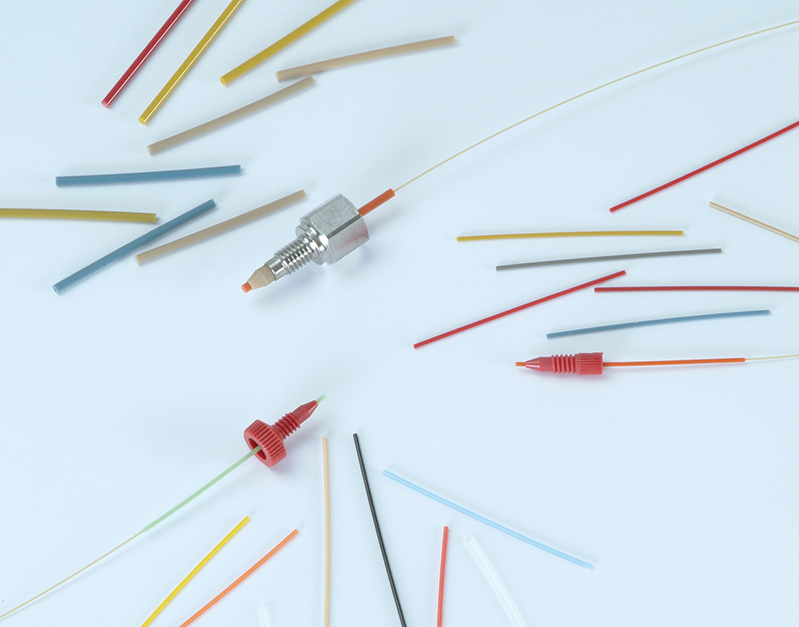

1/32” OD FEP Tubing Sleeves

Clockwise, starting at top:

- 1/16” OD PEEK Tubing Sleeves, use with U-400 and U-401 (not shown)

- 1/32” OD FEP Tubing Sleeves, shown with F-126Sx Fitting

- Fittings and tubing only shown to highlight how sleeves are designed to be used; they are not included with the sleeves

These 1.6” long sleeves facilitate connecting capillary tubing into ports designed for1/32” OD tubing. These sleeves can be used at up to 50 °C and have a pressure rating of 1,750 psi (121 bar).