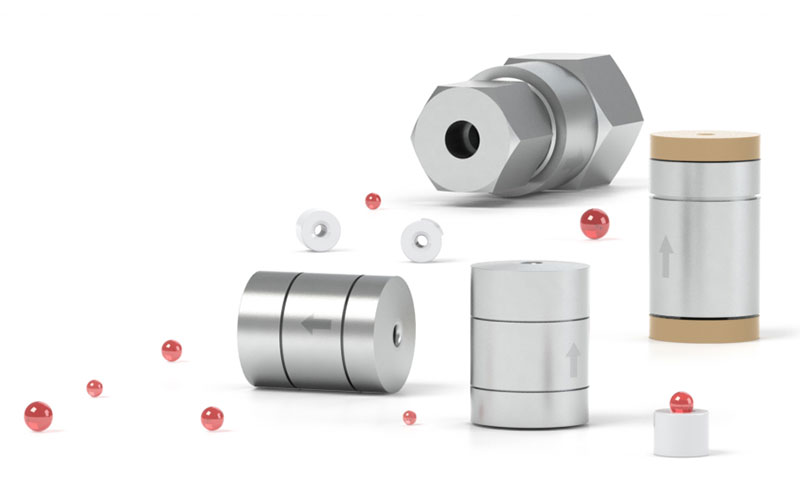

Check Valves for HPLC Pumps

One of the most integral components of a High-Performance Liquid Chromatography (HPLC) Pump is the Check Valve (CV). This one-way valve allows fluid through in only one direction by preventing backflow. The most common type of check valve used in an HPLC pump is the ball / seat. In this configuration, the ball makes a seal when seated on the complementary spherical sealing surface of the seat component. Most ball / seat check valves use gravity or reverse flow to create a seal.

Best Way to Maintain Check Valves?

- Ball and Seat Material

- Ball and Size Grade

- Ball Height

- Ball Movement

- Sealing Surface of the Ball Seat

- Torque

Your Comprehensive Guide to Check Valves

This white paper covers the critical elements related to the functioning of a check valve. The various attributes described have a significant impact on check valve performance. All this ultimately affects the overall chromatography pump performance and the resulting chromatography readings. It is important to customize the design of the appropriate check valve to meet the specific application needs.

At IDEX Health & Science, we understand the impact of all these attributes to the optimal functionality of a check valve and its impact to the preventative maintenance cycle. With our design expertise and simulation capabilities, we leverage the right attributes to manufacture a check valve that meets the platform application needs by keeping design for cost central to our discussions.