Ensure a Perfect Connection Every Time with Our MarvelXACT™ Fitting System

Our expertly designed MarvelXACT connection system takes the guesswork out of your process by eliminating the risk of under- and over-tightening, with our patented torque-limiting mechanism. This unique feature provides a haptic “click” feedback when it reaches the optimum torque, assuring a perfect connection every time. Built with sturdy, bioinert PEEK, PEEKsil™, and stainless steel, MarvelXACT can be connected and disconnected more than 100 times. MarvelXACT also incorporates our advanced MarvelX™ Sealing Technology to deliver precise face sealing (sealing at the port bottom), which eliminates additional internal volume, and minimizes carryover risk, peak tailing, and peak broadening. The MarvelXACT connection system incorporates flexible 1/32” OD tubing to easily route through your system, is compatible with 10-32 coned receiving ports, and is absolutely finger-tight — no tool required. Additionally, MarvelXACT utilizes our exclusive next-generation patented technology to auto-adjust to various port depths.

MarvelXACT Trouble-Free UHPLC Connections

- No risk of under- or over-tightening with torque limiting mechanism

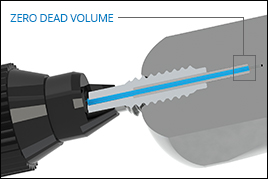

- Face sealing ensures Zero Dead Volume

- Minimize carryover, peak broadening, and peak tailing

- Finger-tight to 19,000 psi

- 100+ connects and disconnects

- No training or instructions needed to make a perfect connection everytime

- Bioinert BioVersal™ PEEK Lined Stainless Steel and PEEKsil Configurations Available

MarvelXACT vs. Conventional Coned Fittings

MarvelXACT Fittings

Conventional Coned Fittings

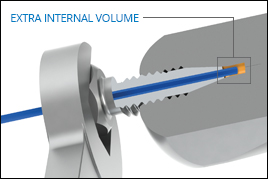

MarvelXACT Fittings do not depend on ferrules. They seal at the bottom of the port, without complex techniques, which significantly reduces required torque and enables many more connects and disconnects. MarvelXACT significantly reduces wear on your hardware, increasing product life. An enhanced proprietary tip design also ensures zero dead volume (ZDV) and better chromatography results. Conventional Coned Fittings require a ferrule in conjunction with a fitting for proper sealing. They depend on complex techniques, including tools, to improve sealing performance, which significantly increases probability of extra internal volume and poor chromatography results. The excessive force needed for tightening increases wear of expensive components and the likelihood of replacement, adding to overall costs.

Contact a MarvelXACT Specialist