Melles Griot® XPLAN™ CCG Lens Series

Fluorescence Microscope Imaging Lenses

Review Specifications Explore Objectives & Download Drawings

Explore Tube Lens & Download Drawings FAQs Request Info and CAD Files

Problem: Struggling to keep up with the fast-paced world of Life Science discoveries and clinical development, where the need for cutting-edge instruments is constant?

Advancements in new Life Science technologies are rapidly changing the way we understand health and disease. These technologies allow scientists and researchers to study cause and effect of diseases and evolutions, come up with new diagnostics, drug targets and therapeutics by interrogating millions of targets at the cellular, sub-cellular, and molecular (DNA/RNA) levels at an unprecedented pace. Fluorescence microscopy plays a critical role in enabling the sub-micron imaging capabilities from Next Generation Sequencing, Next Generation Proteomics, and Spatial Biology instruments.

Moreover, since mission-critical activities at Life Science tool manufacturers are mostly focused on chemistry and biology, there is limited in-house optical engineering and manufacturing resources and capabilities to DIY or recognize the complexity of high precision (>0.5 high NA with large field of view (FOV)) fluorescence microscope systems until it is too late.

The demand for next-generation solutions, driving higher data and sample throughput, lower cost, and superior image quality for applications is at an all-time high. Yet, existing off-the-shelf microscopy solutions are still constrained to size and mounting requirements developed over a century ago.

Custom lenses from a knowledgeable lens provider can fulfill these ever-increasing data capture needs, however not every program can accept the longer lead times and associated development costs.

Solution: IDEX Health & Science sets a new standard with our Melles Griot® XPLAN™ CCG Lens Series fluorescence microscope imaging systems.

Access superior-quality optics with off-the-shelf lead time. We enable the rapid development of breadboard instruments for Next Generation Sequencing, Proteomics, and Spatial Biology applications.

What sets our Melles Griot XPLAN CCG Lens Series apart?

- Large Field of View

The field of view is up to four times existing off-the-shelf premium lenses, translating to high data throughput and faster run times.

- Perfect Field of View

It offers a 100% usable field of view out to the corners of your sensor compared to 10 to 40% on other mid-grade to premium lenses, meaning more usable data, fewer runs, and lower reagent costs.

- Off-the-Shelf Lead Time with Custom Design Performance

In just six weeks, you can have custom lens design performance without the headaches, completing a breadboard design with high-precision optics and a quick time to market.

- Development Budget Friendly

Our lens series gives you access to custom objective and tube lens solutions without upfront non-recurring engineering expenses.

- Flexible Sample Cover Glass Options

A unique feature is the configurable cover glass (CCG) thickness. A one-time factory adjustment can be performed to optimize for cover glasses between 0.17 mm and 1.1 mm. This compares to having to choose between one thin cover glass, or a cumbersome correction collar adjustment.

Melles Griot XPLAN CCG Lens System Specifications

| Mag | Objective Lens NA | Maximum Sensor Format | |||

| 1.1 NA | 0.88 NA | 0.75 NA | 0.5 NA | ||

| Resolution (nm) | 305 | 381 | 447 | 671 | @ 550 nm emission wavelength |

| Max Field of View (mm) | 1.1 | 1.21 | 1.47 | 2.51 | |

| 145 mm Tube Lens | 16.00X | 14.50X | 12.00X | 7.00X | 1.1" Sensor |

| 200 mm Tube Lens | 22.00X | 19.94X | 16.50X | 9.63X | 4/3" Sensor |

| 291 mm Tube Lens | 32.00X | 29.00X | 24.00X | 14.00X | APS-C |

| 400 mm Tube Lens* *Inquire for Lead Time | 44.00X | 39.88X | 33.00X | 19.25X | Full Frame |

Objective Lens Features

Sub-diffraction limited performance is achieved across the field of view, within the stated wavelength and coverglass range, a parameter commonly held in custom designs. All objectives offer precision mounting points, specified in the lens outline drawing.

| Objective Lens | |||||||||||||||||||||||||||||||||||||||

| 1.1 NA Download Drawing (PDF) | 0.88 NA Download Drawing (PDF) | 0.75 NA Download Drawing (PDF) | 0.5 NA Download Drawing (PDF) | ||||||||||||||||||||||||||||||||||||

| Maximum Field of View (mm) | 1.1 | 1.21 | 1.47 | 2.51 | |||||||||||||||||||||||||||||||||||

| Focal Length (mm) | 9.09 | 10.03 | 12.12 | 20.78 | |||||||||||||||||||||||||||||||||||

| Mass (g) | 900 | 720 | 670 | 411 | |||||||||||||||||||||||||||||||||||

| Wavelength Correction (nm) | 436 - 729 | 458 - 729 | 438 - 790 | 438 - 790 | |||||||||||||||||||||||||||||||||||

| Maximum Distortion (when paired with XPLAN tube lens) | 0.2% | 0.1% | 0.2% | 0.2% | |||||||||||||||||||||||||||||||||||

| Transmission @ 633nm | > 73% | > 76% | > 80% | > 80% | |||||||||||||||||||||||||||||||||||

|

|

|

|

| |||||||||||||||||||||||||||||||||||

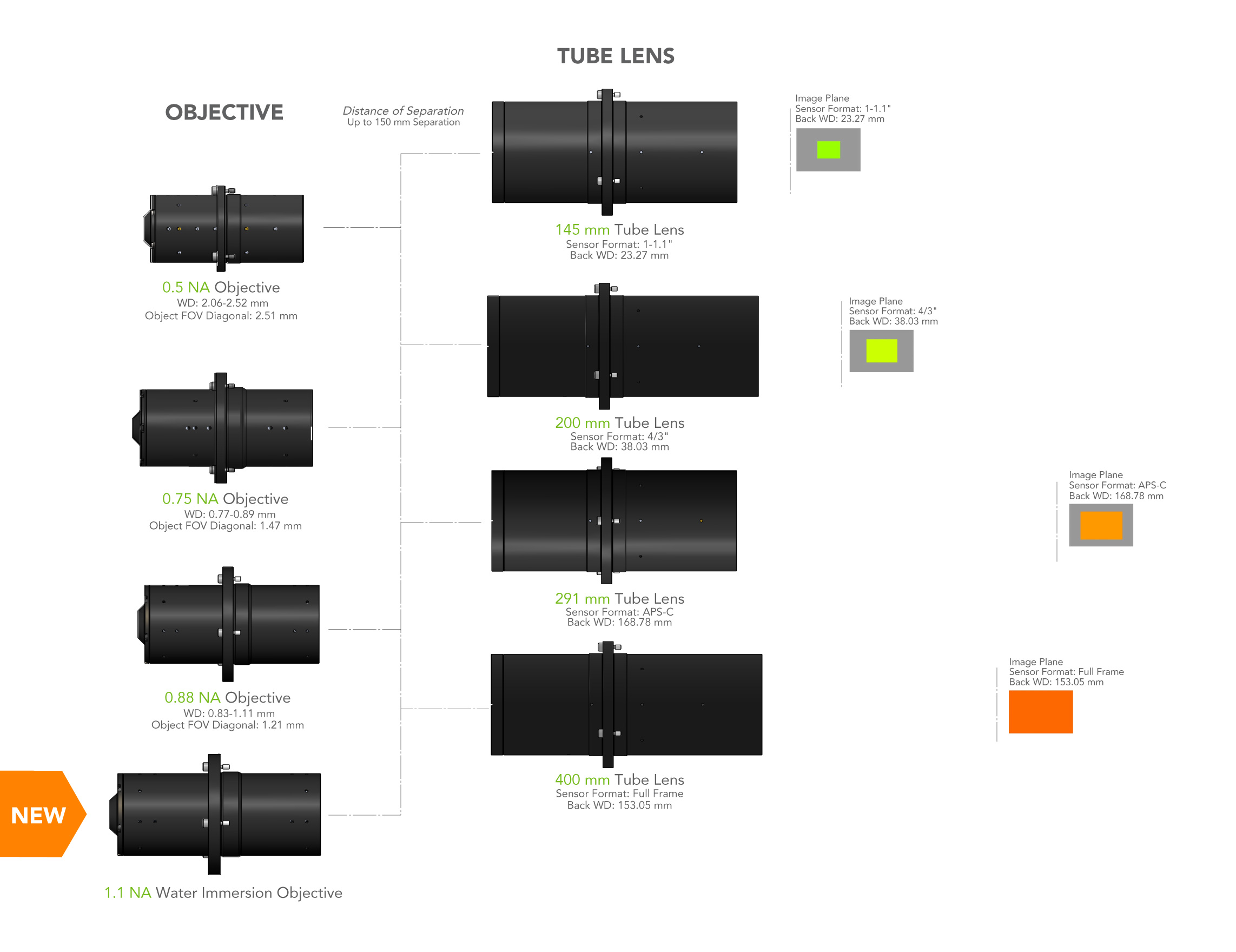

Tube Lens Features

Designed around standard camera formats, the XPLAN tube lens offers edge to edge relative illumination, superior visible wavelength correction and impressively low distortion. All tube lenses offer precision mounting points, specified in the lens outline drawing.

| Tube Lens | ||||

| 145 mm Download Drawing (PDF) | 200 mm Download Drawing (PDF) | 291mm Download Drawing (PDF) | 400mm Download Drawing (PDF) | |

| Sensor Compatibility | 1 - 1.1" | 4/3" | APS-C | Full Frame |

| Maximum Field of View (mm) | 17.6 | 24.2 | 35.2 | 48.4 |

| Focal Length (mm) | 145 | 200 | 291 | 400 |

| Mass (g) | 1000 | 1053 | 918 | 775 |

| Wavelength Correction (nm) | 438 - 790 | |||

| Back Working Distance (mm) | 23.27 | 38.03 | 168.78 | 153.05 |

| Transmission | > 93% @ 633 nm | |||

| Distance from Objective | Up to 150 mm | |||

When Configuring Optics, Consider the Following:

- How can I improve imaging throughput in spatial biology or NGS instruments?

- How do XPLAN lenses compare to traditional off-the-shelf microscope lenses?

- Field of View: XPLAN lenses offer up to four times the field of view, dramatically increasing imaging area and throughput.

- Usable Imaging Area: XPLAN lenses are diffraction limited edge to edge and together with the IDEX Health & Science Laser engines with flat-top even Illumination beam shaping to match the sensor enables 100% usable area.

- Cover Glass Flexibility: The configurable cover glass thickness (0.17 mm to 1.1 mm) eliminates the need for correction collars, simplifying integration.

- How does IDEX Health & Science support optical design for high-throughput imaging platforms?

- Feasibility Phase: During this phase, the feasibility of a concept or technology is demonstrated. This demonstration may be in the form of Concept Demonstration Units (CDUs) which are representations of components, sub-assemblies, or products and how they will function. CDUs are sent to prospective customers for evaluation and feedback.

- Design Phase: During this phase, the product is designed to meet the specified design outputs and end user requirements given the design inputs. This may be a highly iterative process depending on the complexity of the product or technology used. New processes required to manufacture and/or test the product should be tested and proven effective and repeatable in this phase. This phase is characterized by the production of prototypes (as necessary) that are used to assess the degree to which the design inputs match the design outputs and intended use of the product. The results of the assessments are documented by conducting Engineering Verification Testing (EVT) and issuing a formal report of those results. Prior to exiting the Design Phase, Design Verification Testing (DVT) is conducted as an independent verification of EVT results. In addition, product lifetime, the usability of any peripherals associated with the product, and reliable operation of the product in a real-world environment are confirmed.

- Pre-Production Phase: This phase and is used to simulate full scale production, providing the opportunity to make adjustments/changes prior to product release

To improve imaging throughput in these applications, IDEX Health & Science offers the Melles Griot® XPLAN™ CCG Lens Series. This imaging lens offers a field of view four times off-the-shelf premium lenses, 100% usable field of view across the sensor, sub-diffraction limited performance and high numerical aperture (NA) options. These features help support high data throughput, faster run times, and more usable data.

XPLAN lenses outperform traditional off-the-shelf microscope lenses in several key areas:

IDEX Health & Science supports OEM customers through a comprehensive Product Development Process.

Interested in Learning More about the Melles Griot XPLAN CCG Lens Series?

Fill out the form to get started and request access to CAD models.

*Required Field

Upon submission of this form, you will receive an email from IHSmarketing@idex-hs.com to verify your email address. Please open the email with subject line: "Please confirm your email address" and click "I confirm" to complete the request.

Accelerate your development process with this game-changing technology. The IDEX Health & Science Melles Griot XPLAN CCG Lens Series enables the next generation of life science tools design and manufacturing.