Microfluidic Definitions & Specs

Learn about Microfluidic Definitions and Specifications to assist in your understanding of Microfluidic applications.

Listed below are property definitions related to charts on our material properties pages.

Thermal

Annealing PointThe temperature at which internal stresses are substantially removed in a short period of time.

Glass Transition Temperature

The temperature range in which a material transitions from a true solid to a very viscous liquid. This definition applies to non-crystalline solids.

Melting Point

The temperature at which a material turns suddenly from solid to liquid.

Softening Point

The temperature at which a glass deforms at a specific rate under its own weight.

Specific Heat

The amount of energy a body stores per unit mass for each degree increase in temperature (at constant pressure).

Strain Point

The temperature at which internal stresses in glass are substantially relieved in approximately 1 hour.

Thermal Conductivity

The rate at which heat flows through a unit area of homogeneous material for a given temperature difference.

Thermal Expansion

The change in length per unit length of a material corresponding to a unit change in temperature.

Thermal Shock

A parameter that characterizes the material cracking resulting from the temperature gradients caused by rapid change in temperature. A reduction in temperature is usually used for brittle materials.

Optical

Refractive IndexRatio of the speed of monochromatic light in a vacuum to the speed of light through a material.

Transmission Range

Wavelength range light will transmit through a unit length of optical material without significant optical attenuation.

Mechanical

Bulk ModulusRatio of stress to change in volume of a material subjected to axial loading. It is related to the Modulus of Elasticity and Poisson’s Ratio by the following equation: Bulk Modulus = (Modulus of Elasticity)/(3x(1-2xPoisson’s Ratio)).

Compressive Strength

The maximum compressive stress a material can withstand before failure.

Density

Mass per unit volume.

Elastic Limit

Greatest stress that can be applied to a material without causing permanent deformation.

Flexural Strength

Maximum stress developed in a specimen just before it cracks or breaks in a flexure test.

Poisson’s Ratio

The negative ratio of the thickness decrease divided by the length increase resulting from a tensile stress applied to a material.

Porosity

The proportion of the non-solid volume to the total volume of material.

Shear Modulus

The proportionality constant between elastic shear stress and elastic shear strain of a solid material subjected to shear loading.

Shore Durometer

Shore Durometer is a measure of hardness commonly used with rubbers, elastomers and polymers. Like all hardness testers, the Shore Durometer test measures the depth of an indentation under a given

test force. There are no less than 12 Shore Durometer scales, with the two most common being the Durometer Shore A and D scales. The Shore A scale used for softer materials and the Shore D scale is for harder ones. The primary differences

between the two scales are the force range and indenter shape used during the tests.

All scales range in numbers from 0 to 100, with higher numbers indicating harder materials. For reference, provided below are the Durometer values for a few common materials:

- Rubber Band: 25 Shore A

- Automotive Tire Tread: 70 Shore A

- Hydraulic O-Rings: 70 – 90 Shore A

- Hard Hat: 75 Shore D

Tensile Strength

The maximum tensile stress a material can withstand before rupture.

Torsional Strength

The maximum torsional stress that a material can withstand before rupture.

Yield Strength

Maximum stress that can be developed in a material without causing plastic deformation. It is the stress at which a material exhibits a specified permanent deformation and is a practical approximation

of elastic limit. The amount of permanent deformation used depends on the material (for metals it is 0.2% strain).

Young’s Modulus

The proportionality constant between elastic stress and elastic strain for a solid material subjected to uniaxial loading. This property describes the inherent stiffness of a material.

Reference MIL-O-13830 Optical Components for Fire Control Instruments; General Specification Governing The Manufacturing, Assembly, and Inspection of Glass and BSR/OEOSC OP1.002 Optics and Electro-Optical Instruments – Optical Elements and Assemblies – Appearance Imperfections.

Scratch-Dig refers to the quality of optical surfaces. Owing to their relative complexity, many misconceptions exist about the meaning of scratch-dig specifications, and how they are applied. Conceptually, scratch-dig specifications attempt to set a limit on the amount of area surface defects occupy relative to the overall clear aperture of the optical element. Because assessments are made relative to the size of the part, a scratch that is unacceptable for a small part may be acceptable for a large part.

Much of the confusion about scratch/dig requirements finds its origins in the fact that there are actually two distinct standards – the “visibility method” and the “dimensional method”. These two standards differ only in the way scratch widths are categorized. The dimensional method, which is less prevalent, characterizes scratches by width measurements; whereas, the visibility method uses comparisons to commercially available visual references.

Scratch: Any marking or tearing of the part surface.

Dig: A small rough spot on the part surface similar to a pit in appearance. A bubble is considered a dig. Surface stains are also considered digs.

Visibility Method

Scratch/Dig: Surface quality is specified by a number such as 60/40. The 60 defines a scratch width according to a visual standard (it does not mean a scratch can be 60 um wide). For reference, scratch numbers of 60 typically refer to maximum allowable scratch widths of ~7um to 8um. With this in mind, the scratch part of the specifications includes the following four requirements:- The combined length of the scratches with the specified scratch number shall not exceed 25% of the smallest dimension of the clear aperture (*).

- When scratches with the maximum allowable scratch number are present, then the sum of the products of the respective scratch numbers times the ratio of their length to the smallest dimension of the clear aperture for all scratches cannot exceed 50% of the maximum allowable scratch number.

- When scratches with the maximum allowable scratch number are not present, then the sum of the products of the respective scratch numbers times the ratio of their length to the smallest dimension of the clear aperture for all scratches cannot exceed the maximum allowable scratch number.

- Surface with scratch letter requirements between 10 and 20 can have no more than 4 separate scratches in any 0.25 inch circular area.

The second number of the Scratch-Dig specification refers to digs, and establishes a limit to the actual size (diameter) of the digs in hundredths of a millimeter. The dig part of the specifications includes the following three requirements:

- The maximum number of digs must be less than 1 per 20mm diameter circle.

- For every 20mm diameter clear aperture, the sum of the diameters of all digs exceeding 2.5um in diameter cannot exceed 2 times the specified dig letter.

- Digs with a dig number less than 10 must be at least 1mm apart.

Dimensional Method

Scratch/Dig: Surface quality is to be specified by letters such as E/D. The first letter relates to the maximum width allowance of a scratch as measured in microns. The next digits indicate to maximum diameter allowance for a dig in hundredths of a millimeter. A surface quality callout of E/D would permit a scratch width of 60 microns (0.0024″) and a dig diameter of 400mm (0.0158″). The table below provides the correspondence between letters and physical sizes. Note that the scratch and dig accumulation rules for the dimensional and visibility methods are the same, but are repeated below for completeness. With this in mind, the scratch part of the specifications includes the following four requirements:- The combined length of the scratches with the specified scratch number shall not exceed 25%of the smallest dimension of the clear aperture (*).

- When scratches with the maximum allowable scratch width are present, then the sum of the products of the respective scratch widths times the ratio of their length to the smallest dimension of the clear aperture for all scratches cannot exceed 50% of the maximum allowable scratch width.

- When scratches with the maximum allowable scratch width are not present, then the sum of the products of the respective scratch widths times the ratio of their length to the smallest dimension of the clear aperture for all scratches cannot exceed the maximum allowable scratch width.

- Surfaces with scratch letter requirements between B and C can have no more than 4 separate scratches in any 0.25 inch circular area.

The second letter of the Scratch-Dig specification refers to digs, and establishes a limit to the actual size (diameter) of the digs in hundredths of a millimeter. The dig part of the specifications includes the following three requirements:

- The maximum number of digs must be less than 1 per 20mm diameter circle.

- For every 20mm diameter clear aperture, the sum of the diameters of all digs exceeding 2.5um in diameter cannot exceed 2 times the specified dig letter.

- Digs with a dig letter less than B must be at least 1mm apart.

(*) – Note that the length descriptor of the clear aperture is not always simple. MIL-O-13830 defines the length descriptor as the diameter of a circle with the same area as the clear aperture of the part being evaluated. Often times, however, optical industry prefers to use the smallest dimension of the clear aperture.

Dig Identification

| Dig ID | Maximum Dig or Bubble Diameter | Dig or Bubble Separation Distance | ||

| Letter | mm | inch | mm | inch |

| A | 0.05 | 0.0020 | 1.0 | 0.040 |

| B | 0.010 | 0.0039 | 1.0 | 0.040 |

| C | 0.20 | 0.0079 | 20 | 0.787 |

| D | 0.40 | 0.0158 | 20 | 0.787 |

| E | 0.60 | 0.0236 | 20 | 0.787 |

| F | 0.80 | 0.0315 | 20 | 0.787 |

Surface roughness is a measure of the texture of a manufactured surface. Although there are many definitions of surface roughness, all of them are based on a statistical representation of the high frequency surface deviations (peaks and values) from the local mean surface height. Filtering is used to separate the high frequency texture data from lower frequency machining features.

Surface roughness can be measured using contact methods involving dragging a stylus across the part, or using non-contact optical methods. CiDRA® Precision Serivces, LLC uses both measurement methods.

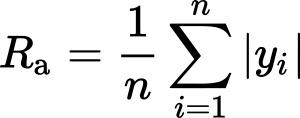

Ra, the most commonly used surface roughness definition, is expressed mathematically by

where n is the total number of data points used in the calculation and Y is the vertical surface position measure from the average surface height. To be applied properly, this line measurement should

be made perpendicular to machining lay marks. Visit Wikipedia.org/wiki/Surface_roughness for a more in-depth explanation

of surface roughness.

Materials We Machine

We have developed capabilities to easily fabricate precise custom products from glass, ceramic, sapphire, hard metal, and many other materials. Our capabilities enable machining of a wide range of materials, of which the most common selections are listed below. If your material of choice is not listed, please don’t hesitate to contact us. We realize that tomorrow’s high-tech products will require the most advanced material technologies, and we at IDEX Health & Science are always up for a challenge!For a list of definitions of terms used in the material charts on each page, please visit our Material Property Definitions section above.

Glass

- BK7 Glass

- Borosilicate Glass

- Crown Glass

- Fused Silica

- Fused Quartz

- Infrared Transmitting Glass

- Soda Lime Glass

- Vycor®

Glass Ceramics

- AREMCOLOX™

- Foturan®

- Macor®

- Robax®

- ULE® Glass

- Zerodur®

Ceramics

- Alumina Silicate

- Boron Nitride

- Ferrites

- Silicon Carbide

- Silicon Nitride

- Zirconia

Crystalline Materials

- Sapphire

Other

- Carbon Fiber Composites

- Ceramic Matrix Composites

- Metal Matrix Composites

Biology & BioPharma

- Linscott’s Directory of Biological and Immunological Reagents

- Microbe Magazine

- In-pharmatechnolovies.com

- Bio-IT World