Turn Your Workflow Puzzle Into a Fully Unified Fluidic Solution

Designing your fluidic workflow should not be a tangled mess or take months to figure out. What you need is a partner who can turn your application idea into a fully unified solution designed to meet your specifications. Untangle the mess and skip the guesswork by partnering with IDEX Health & Science. Instead of piecing together your workflow components, we can provide sub-system solutions to enhance your systems performance with no compromises.

We bring your solution to life in a variety of sectors:

- Environmental including PFAS-free

- Food and Safety

- Biopharma

- Diagnostics

- Next Generation Sequencing

- Alternative Energy

- Semiconductor

IDEX Health & Science enables your complete analytical workflow with our extensive portfolio of fluidic components, including:

Use the quick links below to learn more.

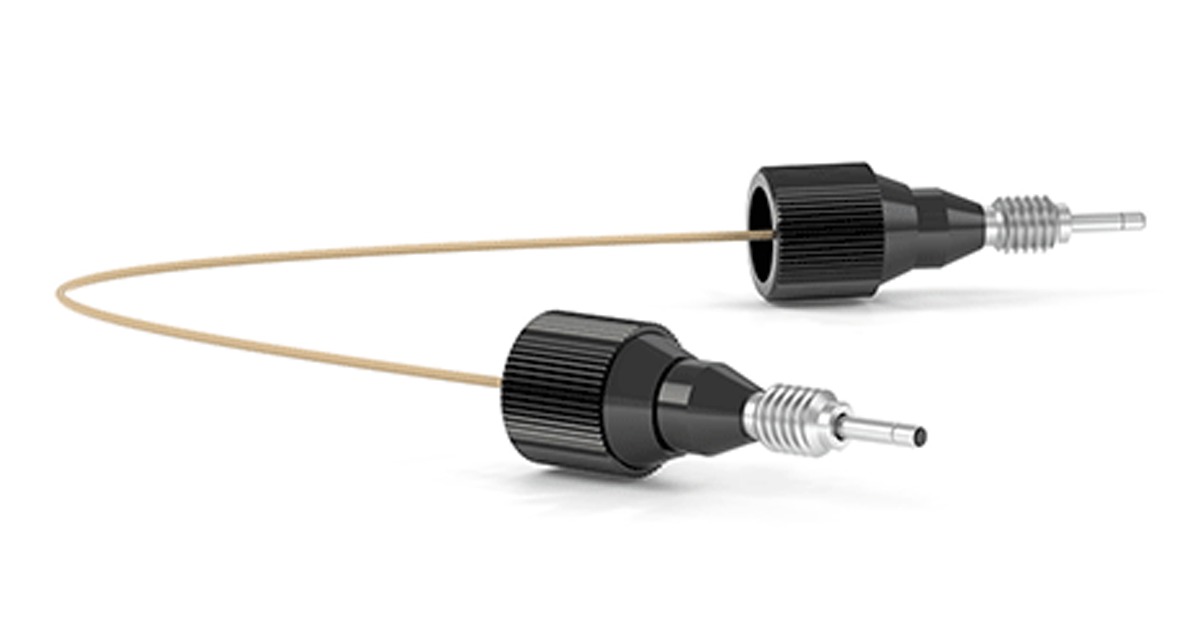

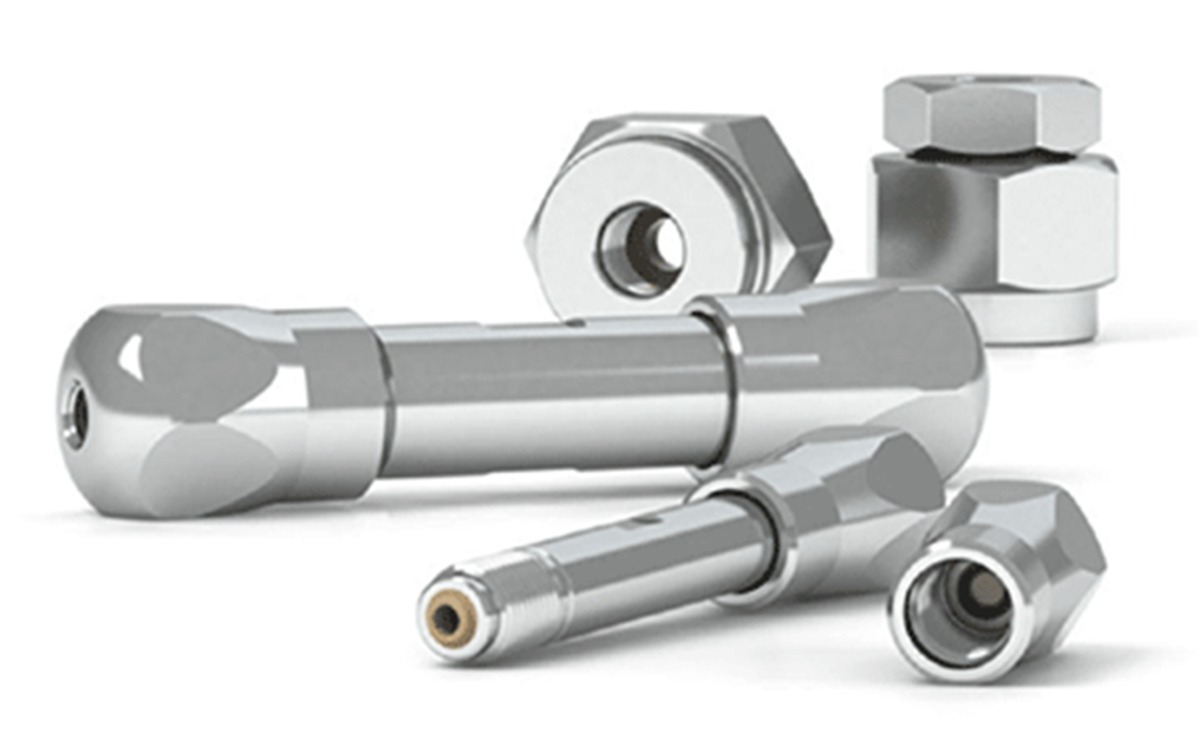

Fittings

Our experts ensure our fluidic connections meet the highest level of quality and margin of safety, so you can have peace of mind.

We have a wide selection of high-pressure HPLC / UHPLC and low-pressure fittings to meet your requirements. We offer many options including bioinert, stainless steel, finger tight, micro, torque limiting, super flangeless, coned, flat bottom fittings. We also offer a portfolio of PEEK tubing fittings, peek connectors, and more.

Contact us today to start a conversation about your next fluidic solution

*Required Field

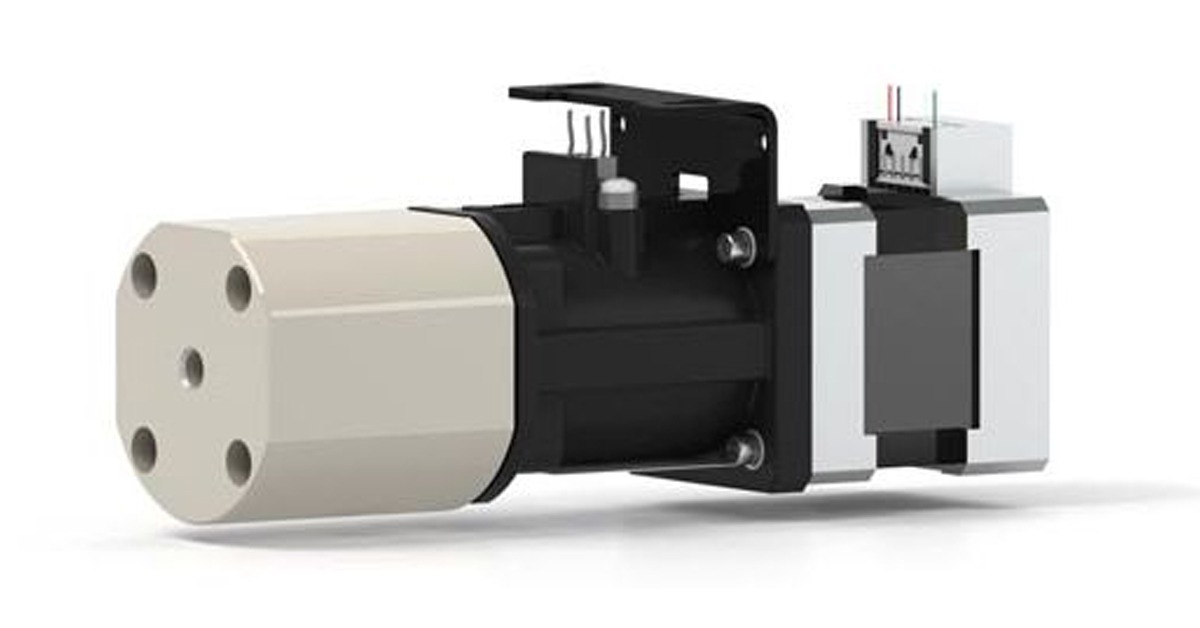

Degassers

Reduce air bubble and dissolved gas interference in your fluidic system and improve the analysis result quality with IDEX Health & Science degassers.

We have developed cutting-edge vacuum pump technology that when paired with our film degasser chamber enables user friendly interface to select a fixed degassing efficiency for a wide flow rate range. This helps reduce pervaporation and extends the life of the pump.

Valves

Whether you are injecting a sample into a HPLC / UHPLC, automating your sample prep dilution, or incorporating a mixing/washing function, our valves can help you direct the flow. Our valves will maintain controlled fluidic conditions to ensure the proper execution of your application.

We are experts in complex flow control, directing your flow path where it needs to go.

Sample Loops

The BioVersal sample loops utilize our unique patented MarvelX technology to auto-adjust to various port depths. The outcome — zero dead volume and better chromatographic results. Our BioVersal™ sample loops are 100% bioinert, making them ideal when injecting biological or “sticky” samples. Loops are available in a variety of volumes to enhance application flexibility.

Zero Dead Volume Connection Systems

MarvelX and MarvelXACT connection utilize advanced face-sealing technology which eliminates additional internal volume, and minimizes carryover risk, peak tailing, and peak broadening.

Our expertly designed UHPLC Connection Systems y eliminate the risk of under- or over-tightening, with our patented torque-limiting mechanism. Built with sturdy, bioinert PEEK, PEEKsil, or stainless steel flow paths, our UHPLC connection systems can be connected and disconnected more than 100 times.

Pumps

We engineer standard and customized pumps to handle your high-throughput demand. Whether your application calls for pumping deionized water or high salinity, detergent-containing fluids, our reliable motorized pistons deliver a consistent flow. Long lifetime is delivered through a highly engineered sealing solution. With wide chemical compatibility, IDEX Health & Science pumps move fluids precisely in your fluidic system while reducing downtime.

To provide flexibility in your workflow design we also offer pump components like piston assemblies, ball seats, and check valves of various material combinations to suit the application need.

Column Hardware

Our column hardware products are designed for optimal packing to deliver the highest efficiency and chromatographic results. Column hardware systems cover pressure ratings from 5,000 psi to 25,000 psi, and are offered in a wide variety of materials, including stainless steel, PEEK, and PEEK-lined stainless steel. They are ideal for a broad range of applications and provide superior separation performance—a crucial factor in reproducibility of analytical data.

Tubing

Our high-quality, versatile tubing is offered in a variety of materials and styles to meet your system requirements. From multiple colors and materials (FEP, PEEK to PFA tubing), our expertise and technology are unmatched.

We can design tubing assemblies to your exact specifications, saving you time and reducing complexity. We extrude, cut, form, test, and label every piece, so you receive a single tubing assembly so they are ready to integrate directly into your system.

Sensors

Easily integrate our sensor into your system for precise pressure monitoring and fluid control.

Our inline pressure sensor provides simplicity and convenience featuring extremely low internal volume and negligible pressure difference. This component combines an entirely separated fluidic pathway, electronics, and I2C communication into a small package.

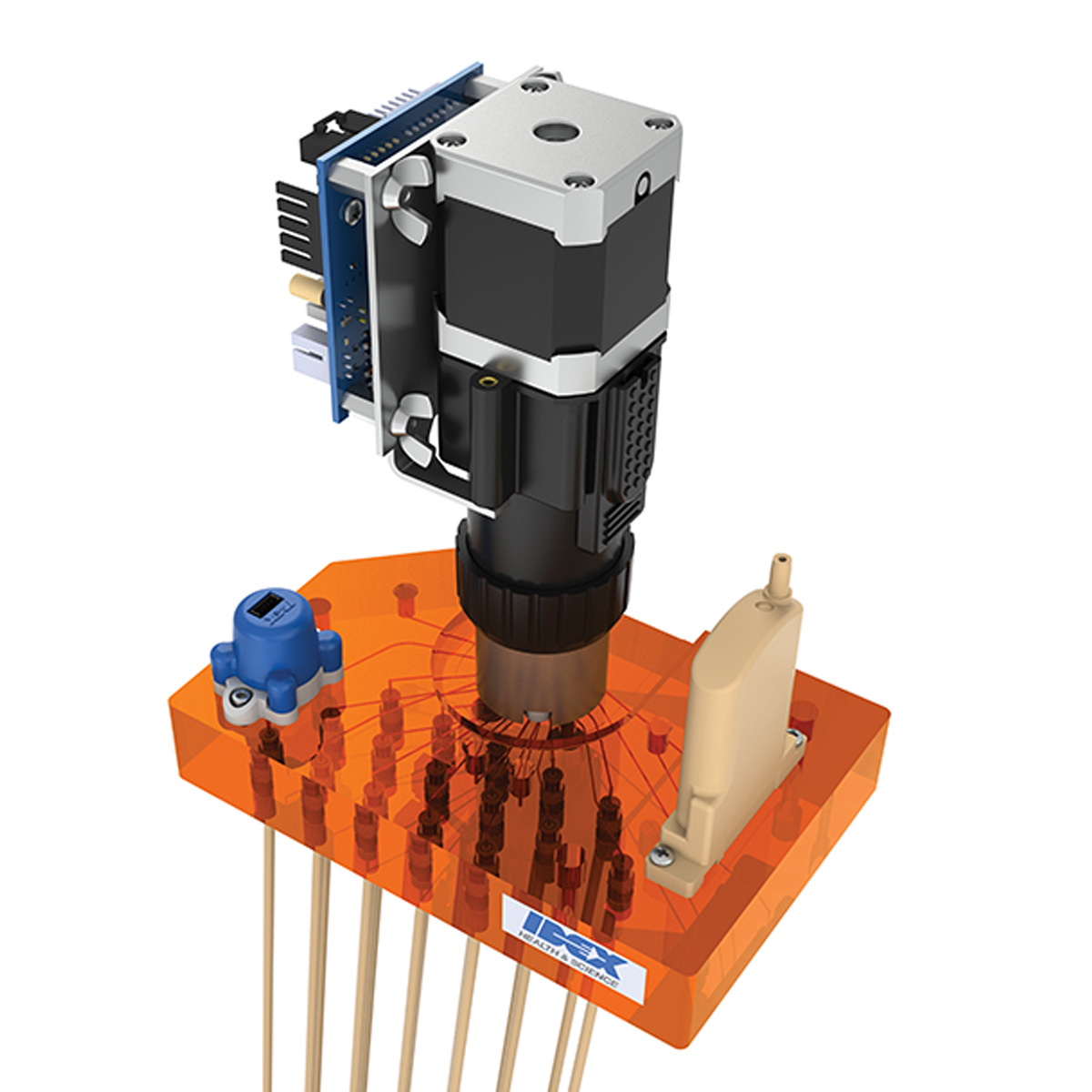

Manifolds

Instrument design may begin as a simple sketch on a whiteboard, but how it comes to life will impact reliability and uptime. We are your full partner for all aspects of fluid movement and plastic machining. Whether you are designing a custom wash station, a fluidic junction point, or connecting to an instrument flow cell, we offer a wide range of materials for custom options to ensure system reproducibility while maintaining tight cost control. Your customized manifold will unify instrument architecture and reduce plumbing complexity, minimize the risk of leak points, and save time during instrument assembly and servicing.

Your Complete Fluidics Subsystem Partner

Don’t waste time tweaking your system with only off-the-shelf components that are not designed to meet your specific needs. Partnering with us can unleash a world of possibilities. We are a one-stop-shop offering turn-key fluidic solutions—your single-source partner for the entire custom fluidic pathway.

Untangle the mess and skip the guesswork by partnering with IDEX Health & Science. We optimize what’s inside the box so you’re free to think outside the box.

IDEX Health & Science develops custom solutions for a wide variety of life science applications, including: