-

IDEX Health & Science Releases BioTight™ Fittings for Low-Pressure Fluidics

Feb 29, 2024 by IDEX Health & ScienceBioTight is ideal for bio markets including genomics, next-generation sequencing, spatial biology, IVD Bio, and Chromatography. BioTight is easy to use, compact, versatile, and metal-free. It’s made with all PEEK components to ensure chemical and biological compatibility.

Full story

-

IDEX Health & Science Releases Melles Griot XPLAN CCG Lens Series

Feb 1, 2024 by IDEX Health & ScienceAttain higher data and sample throughput, lower cost and superior image quality for applications such as next generation sequencing, next generation proteomics, and spatial biology. Learn more about our new product, Melles Griot XPLAN CCG Lens Series.

Full story

-

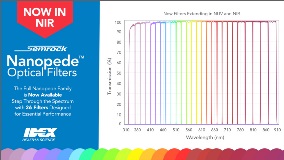

IDEX Health & Science Launches Flow Cytometry Optical Filters

Jan 31, 2024 by IDEX Health & ScienceIDEX Health & Science has launched the new Semrock line of Nanopede Optical Filters specifically designed for flow cytometry applications. These optical filters cover the visible spectrum in 20 nm Full-Width, Half-Max (FWHM) steps. Learn more.

Full story

-

IDEX Health & Science Life Science Optics Team Supports Rochester Community

Jan 25, 2023 by IDEX Health & ScienceIn 2022 alone, the Life Science Optics (LSO) team—working in conjunction with the IDEX Foundation—donated $168,900 to local organizations and hundreds of volunteer hours.

Full story

-

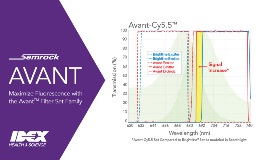

IDEX Health & Science Launches Innovative Avant™ Optical Filter Set Family

Nov 3, 2022 by IDEX Health & ScienceIDEX Health & Science has extended its line of Semrock™ brand optical filters with the launch of the new Avant™ filter set family. This new filter set has been designed to provide significant improvement in fluorescence performance for corresponding short Stokes Shift fluorophores.

Full story

-

IDEX Health & Science Donates $14,500 to Meals For Neighbors Program in Bristol

Sep 23, 2022 by IDEX Health & ScienceIDEX Health & Science’s fluidics team in Bristol, CT recently made a $14,500 donation through the IDEX Foundation to the Meals for Neighbors program at Zion Lutheran Evangelical Church in Bristol.

Full story

-

IDEX Health & Science Donates $15,000 to the Boys & Girls Club of Metro South

Jul 12, 2022 by IDEX Health & ScienceEmployees at the IDEX Health & Science Middleboro facility participated in a clean-up day at the Boys and Girls Club Metro South’s Camp Riverside where they helped prepare the camp for the summer season with various activities. They also made a $15,000 donation through the IDEX Foundation to the Boys and Girls Club of Metro South.

Full story

-

IDEX Health & Science Donates $15,000 to the New York Special Olympics

Jun 20, 2022 by IDEX Health & ScienceIDEX Health & Science’s Life Science Optics Team recently made a $15,000 Donation through the IDEX Foundation to the Special Olympics of New York.

Full story

-

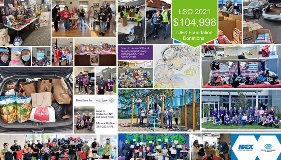

IDEX Health & Science Champions Giving Back to Local Communities

Mar 11, 2022 by IDEX Health & ScienceIDEX Health & Science’s Life Science Optics Team—comprised of units in Rochester, NY Lima, NY and Carlsbad, CA—donated $104,998 in 2021 to local organizations.

Full story

-

IDEX Health & Science Launches Verona™ Optical Filters for Raman Instruments

Jan 19, 2022 by IDEX Health & ScienceThe Verona™ optical filters product line was designed from the ground up specifically for Raman instruments. Understanding that crucial spectroscopic data lies within the fingerprint region close to the excitation laser line, IDEX Health & Science designed the VLP01-785 with a transition width < 29 cm−1 at 785 nm.

Full story

-

IDEX Health & Science Receives the Laser Focus World Innovators Award for their Kola Deep™ Spectral Measurement System

Sep 27, 2021 by IDEX Health & ScienceRohnert Park, California, September 27, 2021— IDEX Health & Science (IH&S), the global leader in optofluidic components and subsystems, announced today that its Life Science Optics business unit has received the Laser Focus World Innovators Award for their Kola Deep™ Spectral Measurement System. This award recognizes excellent innovation, the benefits of which are clear and represents substantial improvement over previous methods employed, approaches taken, or products/systems used, was determined by an esteemed and experienced panel of judges from the optics and photonics community.

Full story

-

IDEX Health & Science Introduces New Partnership Personality Survey

May 18, 2021 by IDEX Health & ScienceRohnert Park, California, May 18, 2021 – IDEX Health & Science (IH&S), industry leader in optofluidic components and subsystems, introduces a new Partnership Personality survey that allows individuals to learn about their view of supplier partnerships as well as, the partnership view of the company they work for.

Full story

-

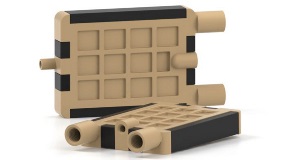

IDEX Health & Science Launches New Intuitive™ Torque Limiting Fitting System

Jan 22, 2021 by IDEX Health & ScienceRohnert Park, California, January 22, 2021 – IDEX Health & Science, industry leader in fluidic connections for life science applications, has launched the Intuitive™ Torque Limiting Fitting System which is a patented torque limiting true “Finger Tight” fitting for low pressure connections. The torque limiting technology provides a haptic “click” feedback when it reaches the optimum torque, assuring a perfect connection every time. This universal fitting can be used with 1/16” & 1/8th” OD tubing.

Full story

-

IDEX Health & Science Launches New MarvelXACT™ PEEKsil™ Connection System

Nov 30, 2020 by IDEX Health & ScienceRohnert Park, California, November 30, 2020 – IDEX Health & Science, industry leader in fluidic connections for life science applications, has launched the new MarvelXACT™ PEEKsil™ Connection Systems. Employing patented MarvelXACT™ connections technology, these new bioinert tubing and fitting connection systems are designed to be compatible with low flow applications at high pressures that require low contamination and minimal flow resistance. The new connection systems have an extremely smooth internal diameter and provide a secure dead volume connection which helps avoid carryover and blockage.

Full story

-

VersaChrome® Tunable Filters from IDEX Health & Science Now Enabling Tunable Raman Spectroscopy

Oct 12, 2020 by IDEX Health & ScienceRochester, New York, October 12, 2020 — IDEX Health & Science (IH&S), industry leader in optofluidic components and subsystems, announces the market expansion of its patented Semrock line of VersaChrome® tunable bandpass and tunable edge optical filters beyond fluorescence microscopy into tunable Raman spectroscopy and hyperspectral imaging applications.

Full story

-

IDEX Health & Science Introduces New Constant Performance Degassing Pump System

Aug 28, 2020 by IDEX Health & ScienceRohnert Park, California, August 28, 2020 — IDEX Health & Science (IH&S), industry leader in fluidic components and subsystems, introduces a new Constant Performance Degassing Pump (CPDP) system that enables a new method of in-line HPLC degassing control that delivers greater HPLC instrument performance and reliability.

Full story

-

IDEX Health & Science Launches BioVersal™ Bioinert Sample Loops

Jul 22, 2020 by IDEX Health & ScienceRohnert Park, California, July 22, 2020 — IDEX Health & Science, industry leader in fluidic connections, introduces its newest addition to their BioVersal™ line of products; zero dead volume bioinert sample loops for use in Ultra High-Pressure applications.

Full story

-

IDEX Health & Science Ships 5 Millionth Semrock® Optical Filter as Demand Increases Due to COVID-19

Apr 24, 2020 by IDEX Health & ScienceRochester, New York, April 22 2020— IDEX Health & Science (IH&S) announced it has reached a major milestone, shipping its 5 millionth Semrock optical filter. IH&S design and process control of Semrock optical filters provides the life science market with an important and robust component that has become widely accepted as the industry standard. More recently, Semrock optical filters have played a role in detecting (through PCR instruments) and monitoring (through sequencing instruments) the SARS-CoV-2 virus that causes COVID-19 resulting in a significant increase in demand.

Full story

-

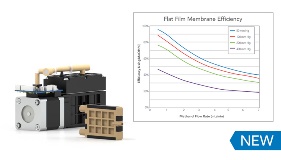

IDEX Health & Science Launches Revolutionary Film Degasser for Enhanced HPLC Performance

Dec 17, 2019 by IDEX Health & ScienceRohnert Park, CA, December 17, 2019 — IDEX Health & Science, LLC (IH&S), the global leader in life science fluidics and optics, today unveiled its new Flat Film Membrane Degasser. In a radical transition from traditional lumen designs, IDEX presents a new cutting-edge technology that provides powerful performance control with increased solvent compatibility. The film degasser provides improved performance and efficiency in a smaller footprint device and the control methodology shifts the emphasis from ‘constant vacuum’ to ‘constant performance’, by allowing users to select an optimal degassing efficiency for any HPLC methods.

Full story

-

IDEX Health & Science Opens New Optics Center of Excellence in Rochester, NY

Nov 14, 2018 by IDEX Health & ScienceRohnert Park, CA, November 12, 2018 — IDEX Health & Science, LLC today announced the official opening of its new state-of-the-art facility in Rochester, New York that will enable scalable future growth of its optical components, sub-systems, and filters business.

Full story