-

Machining of Plastic Manifolds for Life Sciences

Apr 3, 2024 by IDEX Health & ScienceWhether you are looking for a custom cross-drilled component, a larger diffusion bonded manifold, or anything in between, we can create a solution for you.

Full story

-

IH&S Rohnert Park Honored with Great Teams & Culture Award

Mar 28, 2024 by IDEX Health & ScienceOur Rohnert Park site received IDEX Corporation’s Great Teams & Culture award for their efforts to continuously develop and uphold their premier culture.

Full story

-

MyLight™ Tutorial

Mar 21, 2024 by IDEX Health & ScienceWelcome to MyLight™, our online optical filter modeling tool that allows you to quickly characterize the theoretical spectral behavior of our Semrock filters under various conditions.

Full story

-

Custom Part Builder Tutorial

Mar 20, 2024 by IDEX Health & ScienceExplore the newest feature of our Custom Part Builder: instantly check the availability of in-stock optical filter products with this step-by-step tutorial.

Full story

-

IDEX Health & Science: Proteomics Video Series

Mar 12, 2024 by IDEX Health & ScienceProteomics is a new frontier in life science research that will reveal invaluable scientific insights to detect and treat a wide range of diseases. Watch our video series to learn more and how IDEX Health & Science can help you develop your Proteomics platform.

Full story

-

Six Benefits of the BioTight Fitting

Feb 29, 2024 by IDEX Health & ScienceBioTight™ is the newest fitting combination from IDEX Health & Science. While it may be small and compact, it boasts several key benefits that are ideal for low-pressure fluidic applications.

Full story

-

Meet the Experts: Elizabeth Bernhardt

Feb 23, 2024 by IDEX Health & ScienceMeet one of the experts behind our innovations and technologies: Elizabeth Bernhardt, Ph.D.. Elizabeth joined the IDEX Health & Science team three years ago as an Application Scientist.

Full story

-

BrightLine LED-Optimized Fluorescence Filter Sets

Feb 7, 2024 by IDEX Health & ScienceOver the past decade, LED-based light engines have largely replaced gas-discharge lamps (or arc lamps) for fluorescence imaging because LEDs enable faster channel switching, deliver discrete output wavelengths, consume less energy, and offer significantly longer lifetimes. Explore Semrock solutions with our BrightLine Filter Sets.

Full story

-

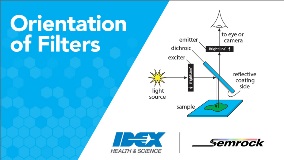

Orientation of Filters

Feb 7, 2024 by IDEX Health & ScienceExplore our guide for how to properly orient your filters. Because of the durability of Semrock filters, you can easily populate filter cubes, filter sliders, and filter wheels yourself without fear of damaging the filters.

Full story

-

Step Up Your Research and Instrument Performance

Feb 5, 2024 by IDEX Health & ScienceStep up your research and instrument performance. Scientists trust Semrock quality: explore the published work of those who have cited Semrock optical filters in their research.

Full story